Altair® Inspire™ Print3D

Efficient Design for Additive Manufacturing

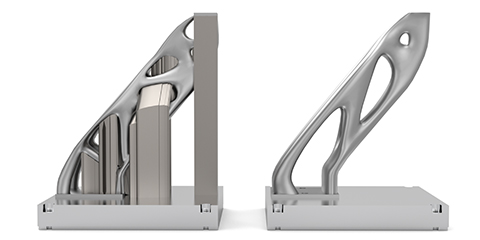

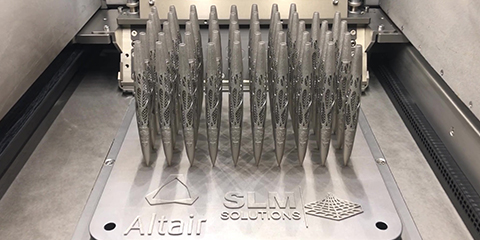

Join the additive manufacturing (AM) revolution of optimized 3D part design and fabrication, which is rapidly being adopted across numerous industries worldwide. Inspire Print3D accelerates the creation, optimization, and study of innovative, structurally efficient additive manufactured parts, providing a fast and accurate toolset for the design and process simulation of parts made by powder bed fusion (PBF) and metal binder jetting (MBJ). By quickly understanding changes to processes or designs that affect manufacturability, engineers can then export the part and support structure geometry to major 3D printer preparation software to produce the part. As a result, Inspire Print3D significantly cuts product development and additive manufacturing costs by reducing material usage, print times, and post-processing.