Additive Manufacturing

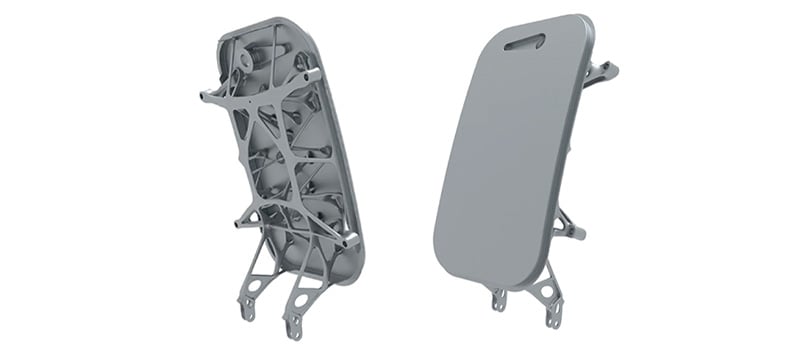

No longer a curiosity destined for mere prototyping and R&D, additive manufacturing (AM) is now a full-scale solution in many industries focused on bespoke or short-production runs. To many manufacturing companies, the solution means a rapid transition into generative design for AM components. Altair provides a powerful, complete solution that helps designers unleash the full potential of AM to create functional, optimized, intricate, organic shapes that would be impossible to develop with traditional manufacturing methods.

Generative Design

Generative design is your next-gen digital copilot for the design journey. Altair’s solutions integrate structural optimization with advanced techniques like topology, topography, and size/shape optimization for the development of lightweight, structurally efficient designs. No other solution on the market combines these capabilities with meshless finite element analysis (FEA), complete kinematic motion simulation, and advanced rendering. Leveraging artificial intelligence (AI) capabilities such as data mining, predictive models, and machine learning, Altair offers comprehensive design exploration through design of experiments (DoE) tools, efficient data storage, and streamlined process automation.

In all, whether considering lattice structures, alternative materials, or thermo-mechanical performance analyses, Altair provides a one-stop shop for industry-leading design intelligence that helps users harness the power of simulation, AI, and high-performance computing (HPC) to develop validated, manufacturing-ready designs.

Implicit Modeling

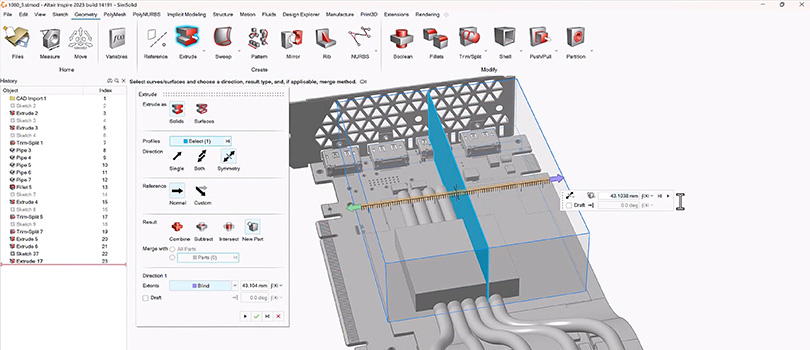

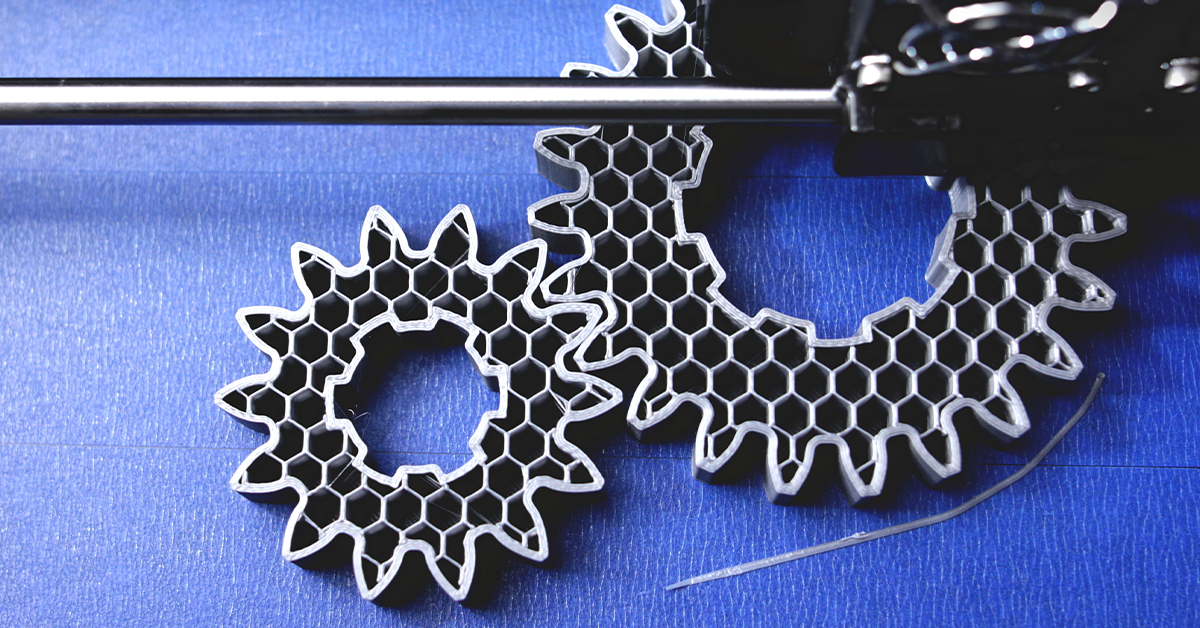

Implicit modeling plays a crucial role in modern engineering simulation and AM. With field-driven design, it enables engineers to generate and optimize aspects of complex systems with unprecedented speed, accuracy, and computational efficiency. Ideally suited for complex geometries, engineers can easily run FEA for complex lattice structures using embedded solvers in Altair® Inspire™ for validation.

Unlock even more possibilities with Inspire’s ease of use and real-time editing to benefit from a novel, modern approach to field-driven design that’s seamlessly integrated with traditional geometry representations such as B-rep and solids.

With familiar CAD workflows, Python API support intuitive Python scripting for unlimited customization, and lightning-fast geometry creation powered by GPU acceleration, Altair's solution brings the power of implicit modeling to designers. Designers can explore and create complex structures optimized for performance and manufacturability using AM processes.

Altair announces material collaboration with HP Inc.

Learn MoreManufacturability

With Inspire’s unique set of simulation tools, users can quickly and easily explore and evaluate product feasibility to select the best manufacturing method for parts. For AM, simulation of the part, its orientation, and the necessary support structures are essential to ensure materials are used efficiently and to avoid thermomechanical problems. Simulate manufacturing for metal binder jetting or powder bed fusion 3D printing processes, then create machine-ready outputs with 3DXpert by Oqton, available via the Altair Partner Alliance.

Unmatched Additive Manufacturing Performance

Embedded early in the design process, Altair combines powerful structural solvers with an extensive design for manufacturing (DfM) platform that enables anyone to create elegant, functional solutions for manufacturability.

Find the best functional shape and material distribution for traditional or advanced manufacturing processes and compare designs while considering multiple manufacturing constraints. Generative design, leveraging the power of AI, surpasses conventional designs by utilizing complex lattice structures to enhance performance, reduce mass, and save costs.

Altair delivers fast design exploration, improved development productivity, and opportunities for part consolidation across various industries. Whether it's aerospace and defense, automotive, state-of-the-art thermal control systems for electronics or energy sectors, or enhancing the quality of medical implants, Altair is at the forefront of driving innovation in design for additive manufacturing (DfAM).

Featured Resources

Designing the Future: Leveraging Simulation, Additive Manufacturing, Generative Design, and AI for Cost-Effective and Sustainable Products

In this panel discussion, Maoz Barkai, Product Manager at Oqton; Dr. Bastiaan Oud, Head of Strategy at SIMCON; and Joseph Flynn, Senior Specialist Simulation & Design Development at Altair, will delve into the latest innovative technologies and techniques used to create high-performing, sustainable, and cost-effective products. Drawing on their expertise, our panelists will explore how simulation, additive manufacturing, generative design, and AI can be leveraged to optimize product performance, reduce design and manufacturing time and costs, and advance sustainability goals. They will also examine the challenges and opportunities associated with incorporating these technologies into product development workflows. Whether you're a product designer, engineer, or sustainability professional, this discussion promises to offer valuable insights and inspiration for harnessing cutting-edge technologies to develop products that meet your performance, cost, and sustainability objectives.

Presented as part of Altair's 2023 Future.Industry conference.

The presentation is in English by default. The following languages are available by clicking on Audio Description 'AD))' on the video screen: DE, ES, FR, IT, ES, PT, KO, and CN.

Duration: 32 minutes

Boosting 3D Printing Design with Simulation

Ford Motor Company began working with Altair more than 30 years ago to support the company’s product development activities. Today, the company employs Altair software globally to support the development of Ford cars, trucks, and heavy equipment. In this customer story, Ford Mexico team using Altair Additive Manufacturing and Optimization Solutions, created brackets with a better mechanical behavior and a more effective heat dissipation.

Expert Chat: Simulation-Driven Design for Manufacturing

Ravi Kunju, Chief Product and Strategy Officer at Altair, discusses simulation-driven design for manufacturing.

Presented as part of the virtual ATCx Simulate at Speed of Design on June 28, 2023.

Duration: 22 mins