Material Solutions

Leverage Altair’s material engineering, data organization, and consolidation expertise using the latest database technologies with Altair material solutions. Our material solutions use high-quality reference data and enables the consolidation of extensive proprietary material information intelligence into one secured private source. The solutions cover the processes to collect, prepare, create, share, collaborate, and consume material information from anywhere.

Enhance your virtual product development with data-enabled workflows that are fully integrated into computer-aided processes. Fill gaps and digitalize new material development with artificial intelligence (AI). Control material compliance, reduce lead time, accelerate time to market, and minimize business risks through consolidated data and processes like never before.

Data and Simulation-Driven Sustainable Product Design

Investing in digitalization means investing in success. Altair’s broad, powerful technology portfolio enables sustainable product design, helps organizations transform value chains, and allows users to meet the industry’s sustainability and climate protection goals.

Solve Business Challenges

Universal Material Data Consolidation

Consolidate your material data with a flexible, format neutral material intelligence management framework based on the latest database technology.

Holistic Decarbonization of Mobility

Address mobility challenges and meet ambitious carbon footprint goals with Altair’s broad materials, simulation, data, cloud, and high-performance computing (HPC) solutions portfolio.

Circular Product Lifecycle Management

Increase the use of recyclates and biodegradable materials to achieve product sustainability and circularity.

Comprehensive Material Intelligence Management Framework

Robust Raw Test Data Processing

Generating material properties can be inconsistent, expensive and time-consuming. Altair® Material Modeler™ is a modeling framework that allows users to quickly and accurately process raw test material data and generate required inputs for data export in .txt and CAE formats.

Enterprise-Wide Material Intelligence

Created for any stakeholder, the Altair® Material Data Center™ provides a role-based, enterprise-wide single source of data with full traceability to the source. With it, searching, comparing, and exporting materials from a web-based interface or through direct integration with other applications is easy.

Advanced Material Modeling

Fully integrated with Altair's simulation products, Altair® Multiscale Designer® is a comprehensive framework for developing highly predictive advanced material models. It reduces time and costs thanks to its minimal experimental data requirements.

Altair announces material collaboration with HP Inc.

Learn MoreMaterial Solutions for Sustainable Innovation

Innovate New Materials with AI

Material producers continuously develop and enhance new materials to meet their customers' needs, sustainability goals, and technological challenges. Altair's solutions portfolio optimizes processes, evaluates new material grades, and provides the necessary documentation while enabling global product consolidation and gap-filling with advanced material modeling and AI. Altair’s secure web interface makes sharing datasets with customers’ organizations easy. Best of all, users can also leverage Altair® RapidMiner® – Altair’s game-changing data analytics and AI platform – alongside Altair’s material solutions.

Sustainability and Climate Protection Through Digitalization

Altair offers a robust framework that can be connected to CAD/CAE, product data management (PDM), and enterprise resource planning (ERP) systems, allowing industries to achieve their sustainability and climate protection objectives through:

- Informed material selection

- Sustainable material substitution

- Increased recyclate materials usage

- Bio-based and biodegradable materials

- Holistic carbon footprint assessment

CAMPUS® the Plastics Database

Altair GmbH is the official software supplier to Computer Aided Material Preselection by Uniform Standards (CAMPUS), the world’s most successful plastic material database adhering to rigorous international standards

CAMPUS is the only database which exclusively offers truly comparable material data measured according to binding international standards. It offers valuable material data, including single point values for all relevant categories and extensive multipoint data (curves) with engineering data, chemical resistance and aging properties, powerful search and compare features, and datasheet print functions in ten languages.

CAMPUS is a registered trademark of Chemie Wirtschaftsförderungsgesellschaft mbH (CWFG), Frankfurt/Main.

Comprehensive Plastic Components Development Ecosystem

Altair offers an ecosystem for plastic component development through an extensive high-quality polymer material database, simulation services, and through the Altair Partner Alliance with companies like SIMCON and PART Engineering. This creates the most comprehensive plastics material solution on the market today. The Altair Units licensing model gives users full access to our software at market-leading value, the flexibility to run software anywhere, and the freedom to choose tools from the Altair One Marketplace when needed.

Featured Resources

Product Design for a Global Supply Base, with Confidence in the Material Data, by DuPont

In every development project, choosing the suitable material is a crucial decision with many interdependencies, and especially in globally distributed value chains, this becomes a challenging task. Material Data Access and availability affect engineering, sourcing, technical purchasing, and needs to address many interests.

Beyond material properties to improve performance predictions, more and more sustainability aspects have to be addressed. Learn from Julien Lebranchu, Head of Technical Data Management, how DuPont manages material data, distributes material data to their clients, and their way forward to improve material data comprehensiveness and availability.

Presented as part of Altair's 2021 Future.Industry Conference.

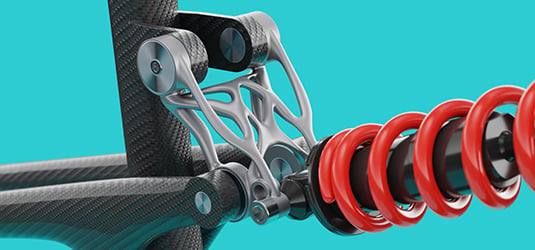

Altair Enlighten Award Webinar Series - Lightweighting Enabling Technology, and Future of Lightweighting

What are some of the innovative technologies/methodologies under R&D to support lightweighting? How have some the latest solutions demonstrated advancements over current industry state-of-the-art standards? What are the lightweighting trends driving the development of technologies in automotive engineering? Meet a few of the Altair Enlighten Award winners for answers to these questions and more! Moderated by Altair's Richard Yen, the webinar highlights the success of the Altair Enlighten Award in elevating initiatives to advance vehicle lightweighting. A panel discussion with leading industry pioneers Frank Billotto from DuPont, Matt Murphy from MSC, Marco Goia from Marelli, and Dr. Stefan Herrmann from csi Group reviews how technology advancements in materials, production processes, design methods, and joining technologies have advanced the impetus for vehicle lightweighting. The panel explores novel, emerging technology solutions, and how they are significantly advancing lightweighting for vehicles.

The webinar and panel discussion was hosted by Altair in conjunction with the Center of Automotive Research (CAR) on March 24, 2021, and is about an hour long.

Sustainability and Climate Protection Through Digitalization

How to choose the right material, the right design, and the right process to develop solutions that minimize carbon emissions and bolster your bottom line.

A step-by-step guide for transforming your plastics engineering value chain to develop solutions that optimize performance, minimize carbon emissions, and gain a competitive edge.

What you will learn:

- Material selection and testing to minimize carbon emissions with Global Warming Potential evaluations alongside traditional performance and cost metrics

- A step-by-step simulation-driven approach to accelerate design space creation, explore variants, and better optimize lightweight plastic parts

- Ways to predict and prevent critical problems such as injection mold core fractures or failures to optimize production operations

- Improve manufacturability using multiscale material modeling

- How to gain a competitive edge with faster time to market through first-time-right injection molding methods, simulation and rapid variant analyses to optimize part, mold and parameters for manufacturing

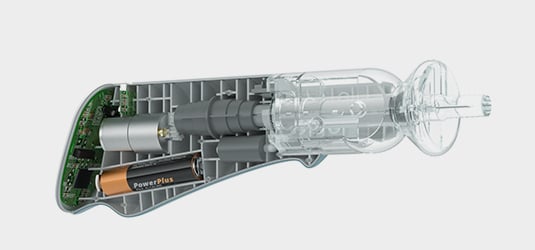

From Metal to Plastics: Sustainability, Lighter Weight at Lower Costs

Altair solutions enable X-Plast to improve a structural part for Knorr-Bremse Rail Systems. Owing to its low environmental impact, rail is one of the most sustainable means of transportation. To ensure a safe and reliable operation of railway components for more than 30 years these parts have to be strong and durable to meet the many requirements. They must withstand extreme temperature and climate conditions, as well as vibrations and high mechanical loads, even impact from stones.