Designing with Engineered Plastics

Engineering plastics offer the design freedom manufacturers need to meet lightweighting and cost requirements for complex parts. High-quality plastic materials can be produced quickly and at high volume, but holistic simulation is needed to tailor materials to the individual product requirements. Altair offers a comprehensive set of engineering plastic solutions to produce innovative plastic parts quickly and reliably.

Sustainability and Climate Protection Through Digitalization

Investing in digitization means investing for success, and the plastic industry needs powerful tools for the development process and beyond. Altair’s broad, powerful technology portfolio enables sustainable product design, helps organizations transform the plastics value chain, and meet the industry’s sustainability and climate protection goals. It also helps organizations:

- Substitute materials

- Increase recycled material usage rates

- Assess and reduce carbon footprint

Optimize Plastic Parts

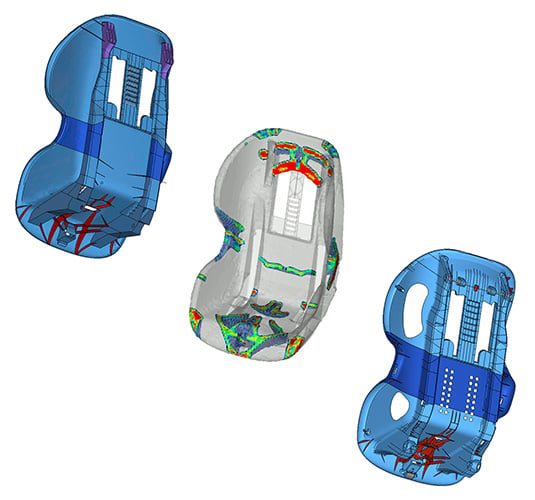

Simulation is often used to validate the performance of a mature component, but if a part has the wrong shape, even the best material cannot compensate for the losses in performance. Modern materials reach their potential in combination with optimal geometric layout, derived from designs tailored to withstand the stresses and strains experienced in operation.

With topology optimizaton, ideal components are designed by determining the most effective material placement and load paths. In later development phases, shape optimization can be used for dimensioning, considering local material effects and allowing for further improvement of the component design.

Master Process-dependent Material Behavior

Modern thermoplastic component development requires companies to consider the manufacturing process, part geometry and material in an integrated simulation approach.

Plastics reinforced with short glass or carbon fibers have anisotropic properties depending on how the fibers align during injection molding Modern optimization methods support part design and development through accurate numerical material description, which considers the typical characteristics of the plastic in the simulation.

Balance Performance and Manufacturability

Simulation offers greater insight into how the modification of manufacturing process parameters may affect component material behavior.

Modern injection molding enables product quality control to ensure part manufacturability during the design process. Engineers can analyze and modify part design while optimizing for form, fit and function.

With Altair’s manufacturing simulation tools, users can analyze mold and feed system designs, single and multi-cavity family mold layouts. They can also improve sprue, runner, and gate position to influence fiber orientations and avoid weakening weld lines.

Holistic Carbon Footprint Assessment and Reduction Technology Demonstrator

Read Article

Accurate Performance Prediction

How can the manufacturing process be taken into account?

The final material is "made" during the manufacturing, so are the final properties and all variations of them. Altair’s integrated simulation-driven design approach starts with the injection molding of the plastic component to improve the prediction of its mechanical performance. Using a modern injection molding simulation as a basis, the anisotropic fiber orientation distribution at each point of the component are transferred to the corresponding areas in the mechanical component. This is provided by a new description of the material which takes the properties typical of the plastic into account in the mechanical analysis including: anisotropy, non-linearity, strain rate dependence, tension-compression asymmetry, failure performance, and dependence on temperature.

Efficient Material Modeling

Altair® Multiscale Designer® increases the precision by capturing micromechanics effects of a fiber reinforced material in a macroscopic FEA representation with reasonable numerical costs. Based on the direction-dependent fiber distribution induced by the injection molding process, the mechanical performance is also described anisotropic using an integrated simulation approach.

Combining a 3D model a single fiber in the plastic, the plasticity and damage laws of the fiber and the plastic materials, and the statistical distribution of the fibers in the plastic, the behavior of the reinforced plastic can be characterized accurately. The fiber orientation distribution of the whole component needed is determined with a beforehand analysis of the injection molding process. Multiscale Designer's material models can be used in implicit and explicit analyses in Altair® OptiStruct® and Altair® Radioss® as well as other 3rd party FEA solvers like ABAQUS, Ansys, and LS-Dyna.

Predict Failure

Plastic components behave very different when they are compressed or tensioned. Properties are nonlinear elastic, load-rate dependent, cyclic loading can cause heating and softening. The same applies for loads along and perpendicular to the fiber direction: plastic fails in terms of anisotropy. These effects require a special modelling of the failure tailored to the plastic.

Fatigue prediction for plastic parts is also crucial in the design process and must consider factors including local component strength, multiaxiality, aging, condition, temperature, and load duration. S-Life Plastics by PART Engineering conducts a short-term, long-term, and fatigue strength assessment for plastic components.

Need a single material resource for your team?

It's Here

Seamless Design Process

Altair offers an open process for the entire development of injection molded components. Using the multiscale technology for the material modeling ensures high accuracy of results. All necessary simulation steps can be done using Altair tools within Altair One™ through the use of Altair's patented licensing system. Proprietary solution for injection molding or structural assessment can be seamlessly integrated. So does the Altair Workflow support your existing process and interfaces with Moldflow, Moldex3D, as well as Abaqus, LS-Dyna or Ansys seamlessly.

CAMPUS® the Plastics Database

Altair GmbH is the official software supplier to Computer Aided Material Preselection by Uniform Standards (CAMPUS), the world’s most successful plastic material database adhering to rigorous international standards

CAMPUS is the only database which exclusively offers truly comparable material data measured according to binding international standards. It offers valuable material data, including single point values for all relevant categories and extensive multipoint data (curves) with engineering data, chemical resistance and aging properties, powerful search and compare features, and datasheet print functions in ten languages.

CAMPUS is a registered trademark of Chemie Wirtschaftsförderungsgesellschaft mbH (CWFG), Frankfurt/Main.

Featured Resources

Sustainability and Climate Protection Through Digitalization

How to choose the right material, the right design, and the right process to develop solutions that minimize carbon emissions and bolster your bottom line.

A step-by-step guide for transforming your plastics engineering value chain to develop solutions that optimize performance, minimize carbon emissions, and gain a competitive edge.

What you will learn:

- Material selection and testing to minimize carbon emissions with Global Warming Potential evaluations alongside traditional performance and cost metrics

- A step-by-step simulation-driven approach to accelerate design space creation, explore variants, and better optimize lightweight plastic parts

- Ways to predict and prevent critical problems such as injection mold core fractures or failures to optimize production operations

- Improve manufacturability using multiscale material modeling

- How to gain a competitive edge with faster time to market through first-time-right injection molding methods, simulation and rapid variant analyses to optimize part, mold and parameters for manufacturing

Designer and Simulation: A Perfect Fit for Sustainable Products

When it comes to plastics, the topic of sustainability is increasingly coming into focus in the industry. The packaging solutions and recycling specialist ALPLA Group, an Austrian company operating internationally has set itself high standards in this regard. To achieve its goals, the company relies on virtual product design to drive its development, with Altair’s adaptive simulation solutions playing a vital role. This article features an actual customer solution to demonstrate the value of simulation and provides an outlook on ALPLA’s future virtual product development strategy, within which the democratization of simulation is particularly important.

Lighter, Stronger, Quieter Vehicles - New Design Space Workflow for Structural Inserts at Sika

Sika is a specialty chemicals company, and a leader in developing and producing systems and products for bonding, sealing, damping, reinforcing, and protecting in the building sector and automotive industry. Offering a wide range of BIW noise reduction and vibration damping solutions and addressing problems encountered in automotive development, Sika is a key development partner for OEMs and suppliers. Sika’s structural systems team focuses on solutions reinforcing the customer’s BIW and NVH issues.

Using the Altair design space workflow, Sika engineers eliminated time-consuming steps in their workflow. This let them make faster decisions - instead of hours in the prior standard workflow, it now only takes minutes. Modeling time was reduced by 70%, giving the team to spend more time gaining a deeper knowledge of the part and its improvement.

Sika won the 2018 Altair Enlighten Award with its ultra-lightweight constrained layer material composite for structure-borne noise reduction.

From Metal to Plastics: Sustainability, Lighter Weight at Lower Costs

Altair solutions enable X-Plast to improve a structural part for Knorr-Bremse Rail Systems. Owing to its low environmental impact, rail is one of the most sustainable means of transportation. To ensure a safe and reliable operation of railway components for more than 30 years these parts have to be strong and durable to meet the many requirements. They must withstand extreme temperature and climate conditions, as well as vibrations and high mechanical loads, even impact from stones.