Heavy Equipment

Heavy equipment manufacturers for construction, mining, agriculture, and off-highway industries face many demanding challenges. Most of all, their equipment must be precise and have the ability to withstand massive loads in extreme environments. To meet the market’s demands and stay competitive they need to continuously improve their machines’ performance and reliability. With Altair’s simulation, artificial intelligence (AI), high-performance computing (HPC), and data analytics solutions, manufacturers can create reliable, high-quality products while reducing costs and the development life cycle. Whether on farms, highways, construction sites, or elsewhere, Altair technology helps you innovate like never before.

Contact UsRevolutionizing Heavy Equipment Design

Accelerate Virtual Prototypes

Large assemblies of thin-walled sheet metal structures, often incorporating various assembly techniques like welding and bolting, are common in the virtual prototypes of construction equipment, agricultural machinery, and trucks. Altair® HyperWorks® is the leading solution for efficiently modeling, simulating, and evaluating both structural integrity and frequency-dependent dynamic behavior in these complex systems.

Get the Most Out of the Season

Cost and performance pressure are always present, especially when facing seasonal testing windows. Altair’s suite of complementary technologies enhances the efficiency of development teams, accelerating the overall process. Leveraging unique AI-Physics predictions, CAD variations can be refined ahead of further validation, while Altair SimSolid® enables designers to reduce CAE iterations. Altair® HyperMesh® empowers CAE analysts with tailored workflows for automated model building, batch meshing, connector technology, model organization, representation handling, and seamless PLM integration. With Altair® OptiStruct®, optimization-driven structural analysis enables the creation of lightweight, structurally efficient designs. Coupled with advanced computational fluid dynamics (CFD) and discrete element modeling (DEM) tools, engineers can simulate and analyze material flow with unparalleled precision.

Revolutionize CAE with Altair® HyperMesh®

Learn MoreAccelerate Digital Twins with Efficient System Models

Altair’s digital twin technology combines AI-powered simulation and Internet of Things (IoT) insights to optimize equipment performance and reduce costs. By leveraging reduced order models (ROMs), these physics- and data-driven digital twins deliver real-time predictions and insights that minimize downtime and warranty expenses. Altair's low-code AI solutions generate ROMs using sensor and simulation data, and our open architecture lets you deploy digital twins on the edge or in the cloud.

Dig Deeper into Design Optimization

Topology optimization opens countless opportunities for lightweighting in an industry dominated by large cast components and weld constructions. Altair’s structural design technology reduces vehicle weight while improving performance. Optimization-enabled structural analysis of advanced noise, vibration, and harshness (NVH) ensures equipment operators always perform at their best.

Early-Stage Simulation-Driven Design

Altair’s simulation-driven design tools enable manufacturers to make informed, reliable product design decisions faster. With intuitive tools designed for geometry creation, simulation, and optimization, organizations can ensure designs’ manufacturability and streamline equipment development. Advanced simulation technology helps organizations perform structural analysis of complex parts and assemblies early in the product development cycle, allowing them to make rapid design iterations and reduce costs.

AI Solutions for a Sustainable Future

Data Analytics for Heavy Equipment

In the heavy equipment industry, where efficiency, safety, and profitability are paramount, embracing cutting-edge AI technologies is no longer optional. Altair RapidMiner, powered by Altair’s groundbreaking AI fabric approach, empowers organizations to address their toughest challenges with transformative AI agents. From optimizing operational workflows to improving customer experience, Altair gives you the tools to enhance productivity, scalability, and decision-making, enabling domain experts to deploy across areas like Smart Factory, supply chain optimization or fleet monitoring.

Transform Heavy Equipment with AI Agents

Altair® RapidMiner® offers a transformative platform for heavy equipment organizations to design and deploy AI agents tailored to their unique needs. By merging advanced data fabric and AI technologies into a cohesive architecture, the platform simplifies complex data ecosystems while enabling scalable, secure, and future-ready AI solutions. Altair RapidMiner enhances this by enabling the creation of knowledge graphs and a semantic layer, allowing users to map, visualize, and analyze relationships within data. This empowers organizations to uncover insights from complex, interconnected data sources. Whether you're addressing specific challenges or pursuing enterprise-wide transformation, Altair RapidMiner’s modular approach and flexible deployment options ensure success at every stage—maximizing the value of your current investments.

Want to accelerate your development with AI-powered engineering?

Learn MoreDriving Heavy Equipment Innovation

High-Fidelity Physics Realtime Ready

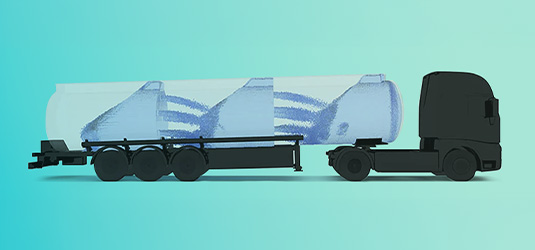

Many control systems – especially those supporting autonomous driving capabilities – require complex high-fidelity system models. Physical simulations, together with AI-powered system-level modeling, can deliver high-fidelity synthetic data to capture the interactions between the equipment and the material, soil, and the ground.

Want to improve your CFD capabilities?

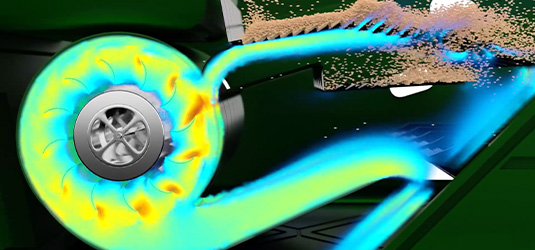

Comply with Noise Regulations

Noise emissions are rigorously regulated in the heavy equipment industry, significantly influencing the development process. By directly simulating fan noise, we can greatly reduce the risk of failure in the physical experiment, leading to lower development costs, faster project timelines, and improved reliability. CFD simulations provide the accuracy required to precisely predict aero-acoustic noise, ensuring optimal performance and compliance.

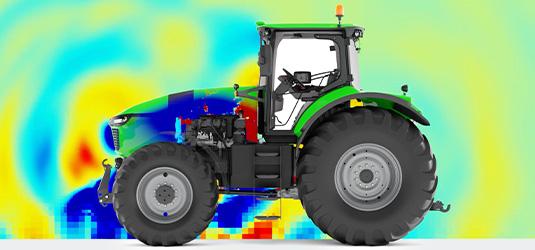

Keep Operators Safe and Comfortable

Operator comfort drives purchase decisions and is a key development goal. Advanced CFD and NVH solutions help keep operators cool and performing at their best. Structural analysis tools model roll-over protection structure (ROPS) and falling object protective structure (FOPS) events to ensure vehicle integrity and protect operators.

Boost Performance with Realistic Loads

Together with DEM applications, customers can optimize designs before building a prototype to quickly and accurately simulate the behavior of bulk materials such as coal, mined ores, soils, fibers, and grains. Coupled together, realistic material loads can be extracted for structural and system dynamics analysis.

Simulate Bulk Material Interactions for Smarter Equipment Design

Manufacturers must design machines that can handle dynamic forces and interact with bulk materials. DEM allows users to simulate material behavior and multibody simulation software models mechanisms’ dynamic responses. Together, these tools help manufacturers optimize designs, extract realistic material loads, and perform structural and system dynamics analysis— all before building physical prototypes.

Evaluate Vehicle Performance

Companies of all sizes – from startups to multinational OEMs – leverage Altair’s DEM applications to test their vehicles virtually in a nearly infinite range of terrain types. Integrating these solutions with multibody dynamics tools provides excellent realism in vehicle mobility simulations. Engineers can accurately predict the behavior and performance of off-road vehicles in a variety of environments and study complex maneuvers.

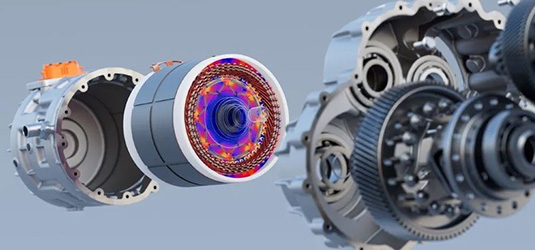

Optimize Electric Powertrain Development

The shift toward hybrid and fully electric powertrain systems presents manufacturers with challenges and opportunities. To align electric equipment development cycles with program timelines, engineering teams must adapt their structures and tools. Powertrains must be optimized for efficiency and lightweight design while also meeting evolving regulations and rising customer expectations. Altair’s solutions for electric powertrain development and integration, battery design simulation, and safety ensure seamless innovation and performance.

Ensure Design Efficiency

Engineering Class A trucks requires a thorough understanding of the dynamics specific to heavy-duty vehicles, including analysis of performance characteristics, mechanical and geometric properties, and overall behavior. Manufacturers are increasingly focused on NVH solutions to improve performance. Investing in advanced end-to-end CAE workflows enhances design outcomes, accelerates development, and reduces cost. These tools help manage greenhouse noise and water wading by simulating flow behaviors and their interactions with heavy vehicles.

Want to improve your efficiency?

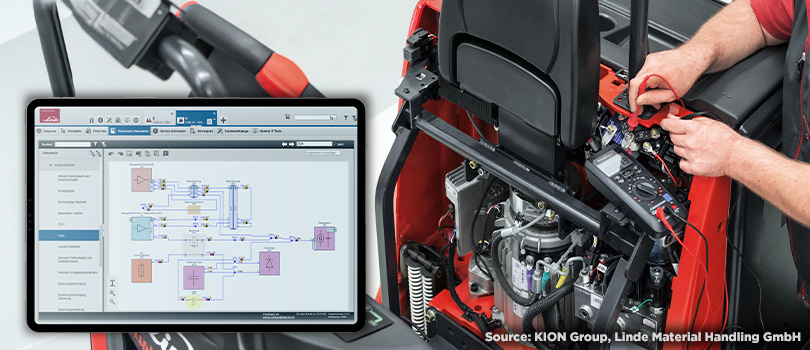

Discover MoreTaming Electrical System Complexity

Electrical system complexity is accelerating. Smart electrical system visualization simplifies this complexity by dynamically isolating and visualizing critical regions. System-rendered displays show up-to-date schematics for system connectivity, wiring harnesses, and component attributes to help development teams, manufacturing teams, and service operations quickly understand complex electrical systems in real time.

Smart Mining, Construction, and Farming

By leveraging versatile and robust AI-powered technology, manufacturers can transform product development processes by making simulations more efficient and more accurate.

Featured Resources

Making Virtual Simulations More Efficient and Accurate with the use of Artificial Intelligence

Giuseppe Gullo, FEA Design Analysis Engineer at CNH Industrial presents at the 2024 ATCx Digital Twin conference.

The use of artificial intelligence is changing virtual simulations, and this presentation will demonstrate how it is possible to speed them up and enhance their capabilities, also considering effects that were much more difficult to include.

The Challenges of Implementing a Simulation Journey in the Off-Highway Industry, presented by Dr. David Panni

The Off-Highway Industry presents many exciting opportunities and challenges for simulation in the Engineering design and development process. This presentation will outline some of the products and the technical challenges in this specific industry.

The presentation will reflect on how simulation tools are currently used in the industry, how they may be used in the future and the key characteristics of the tools to meet the technical and economic challenges ahead.

Applying Machine Learning Augmented Simulation to Heavy Equipment

Simulation-driven design changed heavy equipment product development forever, enabling engineers to reduce design iterations and prototype testing. Increasing scientific computing power expanded the opportunity to apply analysis, making large design studies possible within the timing constraints of a program. Now engineering data science is transforming product development again.

Augmented simulation features inside Altair® HyperWorks® are accelerating the design decision process with machine learning (ML). The power of ML-based AI-powered Engineering combined with physics-based simulation-driven design leveraging the latest in high-performance computing is just being realized.