Altair® Radioss® Applications

Altair Radioss is a powerful, industry-proven, open-platform structural solver for crash, impact, blast, and other nonlinear scenarios. Radioss is used throughout many different industries to resolve numerous explicit dynamics challenges to enhance product safety. Integrating Radioss into the design process helps companies innovate faster, reduce physical prototyping costs, and deliver more advanced products that meet the ever-evolving requirements of their industry.

Learn More About RadiossCrash and Safety

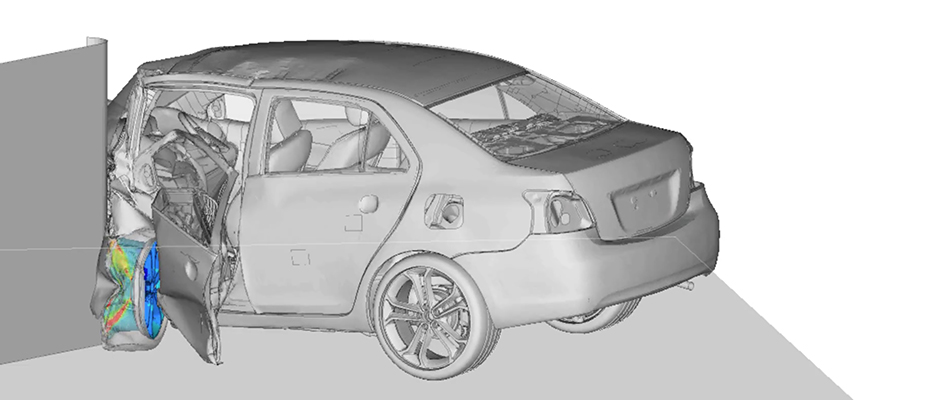

Radioss is a recognized solution for crash testing, safety analysis, and vehicle design optimization. To ensure transportation methods meet ever-stringent safety standards, Radioss' advanced solver technology enables engineers to simulate complex scenarios such as full-vehicle crash, high-speed impacts, and vehicle rollovers. Radioss supports the broader industry shift toward electrification with dedicated material and failure models for detailed analysis of applications like battery systems for electric vehicles (EVs) and urban air mobility concepts (UAM).

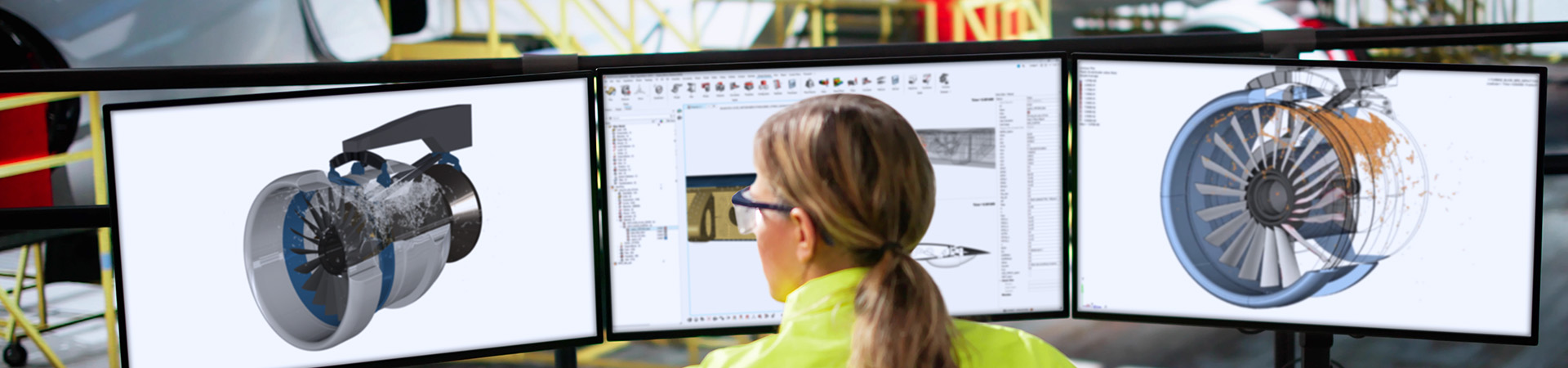

High Velocity and Dynamic Event Analysis

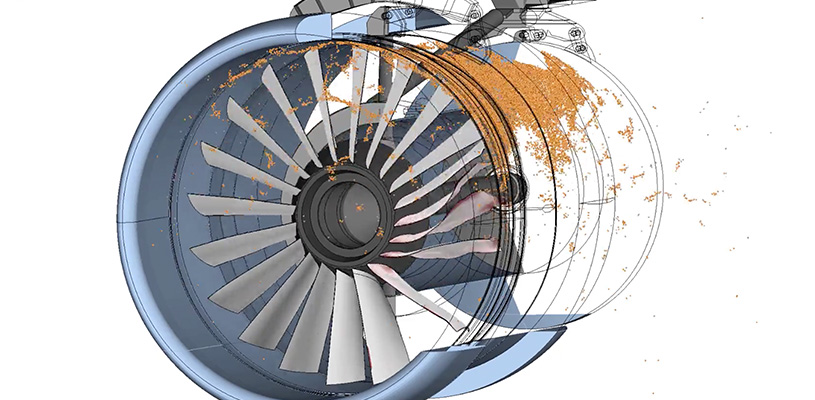

Crucial for ensuring the safety and reliability of large-scale components, Radioss enables accurate simulation of extreme events such as bird strikes, jet engine blade containment, and structural failures. Radioss offers a range of composite material models that are used to ensure performance and efficiency. Validated models for high-impact scenarios, such as bird models, help engineers design for safety and reliability for critical applications such as aircraft windshields and engines.

Blast and Ballistic Analysis

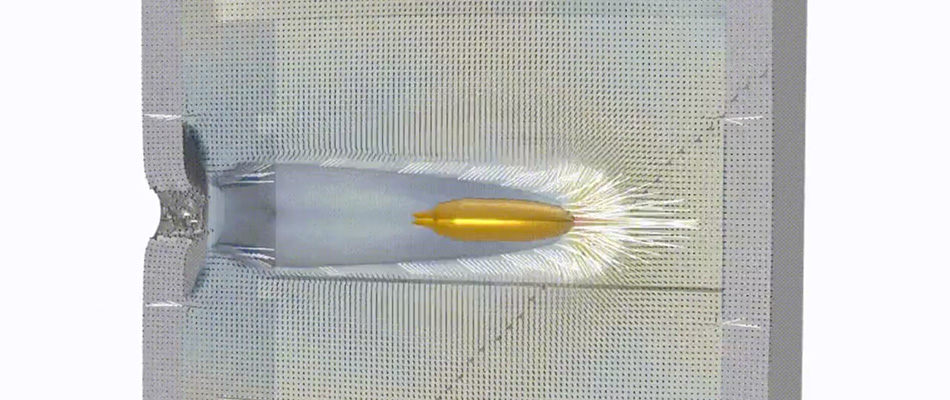

Originally developed to address the extreme load cases found in defense applications, Radioss has evolved into a versatile solution for simulating high-energy events. From blast analysis to ballistic impacts, Radioss helps engineers design safer, more resilient protective systems. With advanced techniques such as the Arbitrary Lagrangian-Eulerian (ALE) method and smoothed-particle hydrodynamics (SPH), Radioss enables accurate simulation of complex interactions in scenarios for protective systems and equipment and critical infrastructure.

How can we help you optimize your product performance?

Contact UsRenewable and Sustainable Energy

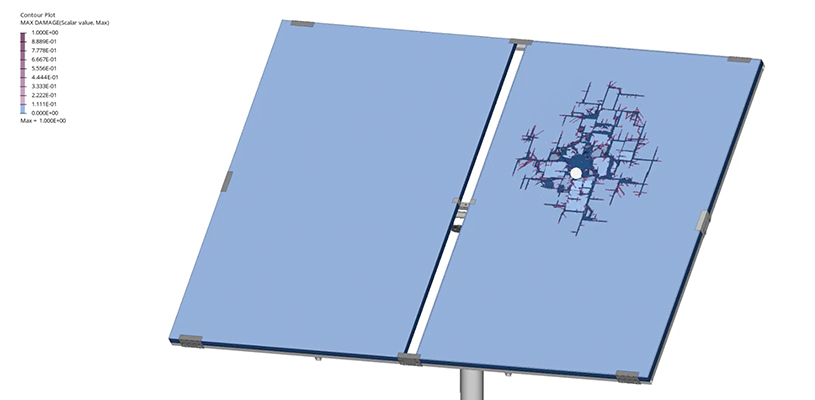

Radioss enables the design and validation of energy systems that must perform reliably under harsh environmental and operational conditions. Engineers can simulate seismic activity and other large, sudden forces that influence the safety and longevity of energy infrastructure. To address climate-driven risks, Radioss also supports detailed simulation of scenarios such as hailstone impacts, helping improve the resilience of components like solar panel surfaces.

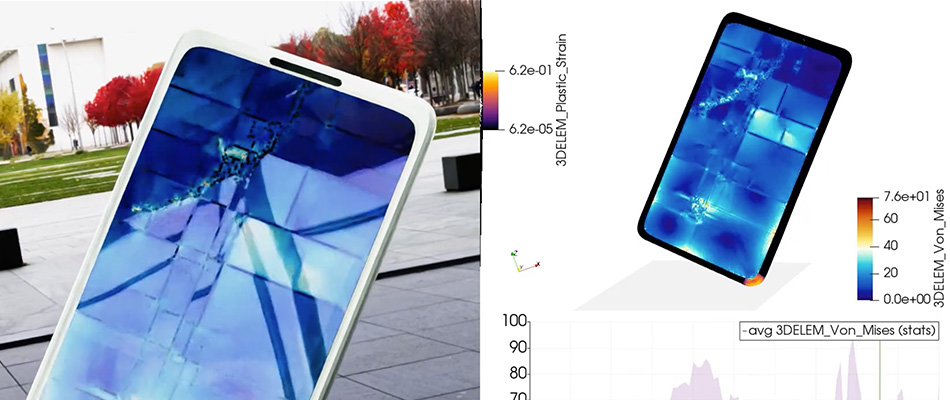

Drop and Impact Testing

Radioss helps engineers enhance the performance and reliability of complex devices by simulating real-world scenarios such as drop tests, impacts, and misuse. These insights enable teams to assess how components like screens, batteries, product casings, and their packaging will behave under shock before physical prototypes are built.

Using advanced material modeling and structural analysis, Radioss also supports the simulation of fabrics, rubbers, and foams to ensure products are durable, comfortable, meet user expectations, and help reduce injury risk.

Material Performance and Fluid-Structure Interaction

Simulating how complex materials behave and interact with fluids under dynamic conditions is critical for designing high-performance systems. Radioss enables detailed analysis of complex nonlinear material behavior, large deformations, and fluid-structure interactions (FSI) to improve safety, reliability, and functionality. These capabilities support a wide range of applications—from bespoke medical and wearable devices to systems where soft materials and fluid dynamics play a key role.

Featured Resources

Improving Comfort and Robustness of Jabra Headsets with Simulation-driven Design, by GN Audio

The usability of a headset is largely determined by a comfortable fit and its resistance to everyday use. Learn from Alice Lin, Manager of Mechanics at GN Audio R&D how she introduced FEM simulation capabilities at Jabra. The presentation shows how product design benefits from structural analysis, design for comfort, and drop test simulation. A future extension of simulation capabilities intends to address more areas and improve the simulation-driven design process efficiency.

Speaker: Alice Lin, Manager of Mechanics, GN Audio

Duration: 22 minutes

Click the AD icon to select alternative audio translations - French, German, Portuguese and Spanish.

Presented as part of Altair's 2021 Future.Industry Conference.

Safety System Simulation with MADYMO-Radioss

The Webinar will outline how engineers can combine the best of both worlds in a single co-simulation environment and gain considerable time saving in vehicle developments. The Radioss-MADYMO coupling solution enables engineers to use the same MADYMO dummy and restraint models in occupant safety analysis as well as in the RADIOSS structural analysis. This removes the need to create intermediate FE models of the restraint system, which reduces development time and provides higher confidence in simulation results.

Assuring Scalability: Altair Radioss™ Delivers Robust Results Quickly for Crash-Safe Vehicle Designs

In the race to deliver safe new vehicles, efficient and accurate simulation of structural performance under different crash scenarios is a key alternative costly physical testing. With growing model complexity, the demand for CPUs is increasing. To assure a fast job turnaround time, HPC and solver scalability is critical. This article shows that by working together with market-leading hardware developers to keep one step ahead of customer needs, Altair Radioss™ offers fast, efficient structural analysis irrespective of the hardware the solver is running on: scalability is proven and assured.

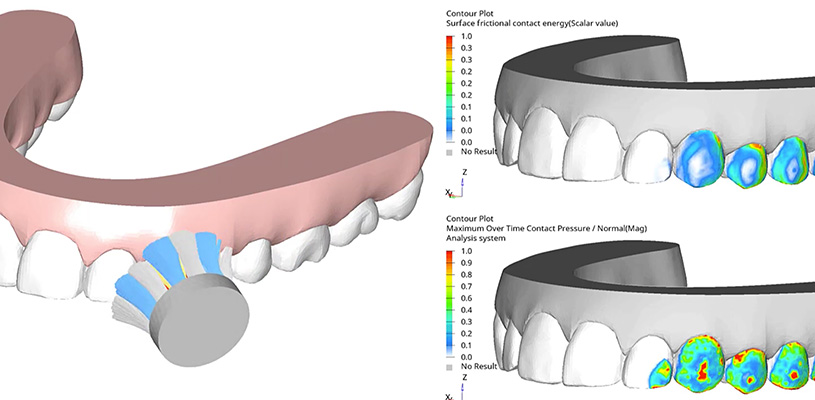

Digital Transformation in Oral Healthcare - iLittleMiracle Uses Digital Twin Powered by Altair® Radioss® for Oral Healthcare Analysis

iLittleMiracle (iLM) was founded in 2011 and is headquartered in Beijing, China. The company is a leading brand that focuses on the early correction of malocclusion and deformity in children between 5 and 12 years old. Through digital innovation, iLM is committed to promoting the continuous innovation and popularization of medical technology for full-cycle facial development management in children.

Orthodontic treatment is one of the biggest categories in dentistry, comprising the highest number of cases each year. As cases increase, it’s crucial to address the shortcomings of traditional, non-digitized methodologies. iLM employs Altair Radioss, Altair RapidMiner, and Altair Monarch, which allow orthodontists to make predictions in a faster, easier way thanks to the tools’ unparalleled simulation and visualization capabilities.