Process Manufacturing

Any industry that produces bulk quantities of goods, including pharmaceuticals, food, chemicals, or cosmetics is seeking to improve product quality and get their products to market quicker. Simulation is increasingly used by engineers and scientists during research, development, and through to process improvement to achieve these goals. The use of computer-aided engineering (CAE) tools reduces development time and dependence on costly physical prototyping and testing.

Increase Process Efficiency

The use of computer simulation in the process manufacturing industries can help improve understanding of processes and provide key insight into operations otherwise difficult or sometimes impossible to obtain. This can result in increased process efficiency and help drive product and process innovation.

Improve Product Quality

Numerical simulation provides the means to control product consistency and quality. It can help companies develop new process strategies and evaluate the effects of process design and scale up on product characteristics. It is a powerful predictive tool that can support the adoption of continuous manufacturing.

How can we help you optimize your processes?

Contact UsMixing

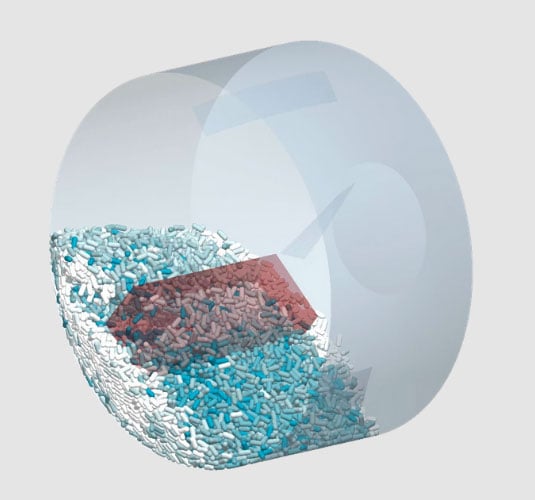

Altair® EDEM™ can simulate the mixing process of powders, tablets, aggregates, and other granular materials. It provides fundamental information such as the particle velocities and trajectories and allows for the prediction of mixing and segregation rates as well as the identification of dead zones. This enables operators to make informed decisions on the optimal process operational parameters for their equipment regarding the impact of speed, fill level, tilt angle, etc., and to assess mixing efficiency.

Tablet Coating

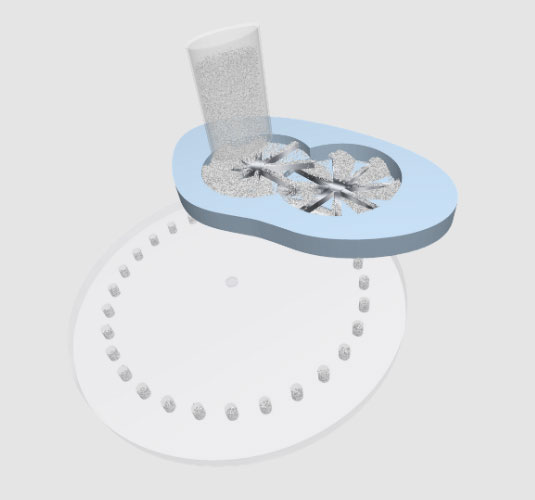

Coating uniformity is of critical importance for the tablet-coating process. With EDEM it is possible to obtain key parameters such as the residence time of the tablets under the coating spray, intra-tablet coating variability, and tablets velocities pattern – many of these are difficult or even impossible to get by experimentation. EDEM can also be used to investigate how the shape of a tablet, the drum’s speed, and the fill level are influencing the coating process.

Die Filling

Die filling is a common step in many industries including pharmaceuticals and powder metallurgy. A consistent and uniform process is very important as it influences the quality of the final product or component. EDEM can be used to assess the effect of various key parameters, understand micro-macro dynamic of particles inside the feed frame, and visualize segregation inside the feed frame and during die filling.

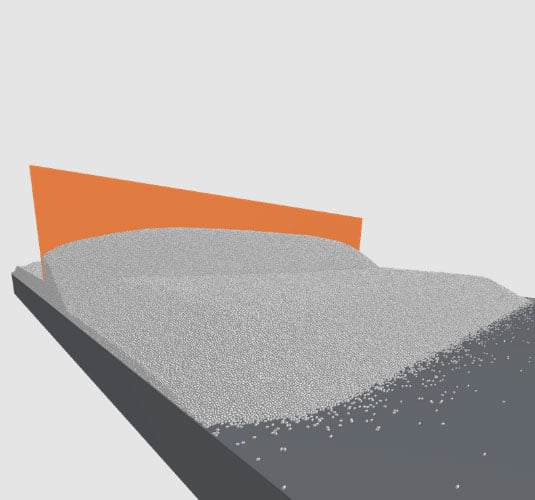

Powder Spreading and Raking

The powder spreading process in additive manufacturing (AM) has a major impact on the characteristics and quality of the final product. EDEM can be used to simulate that process and investigate the impact of different operational parameters such as roller speed on the quality of the powder bed as well as evaluating powder spreading uniformity. EDEM can be applied to various aspects of the AM process including powder delivery, spreading, and cleaning operations.

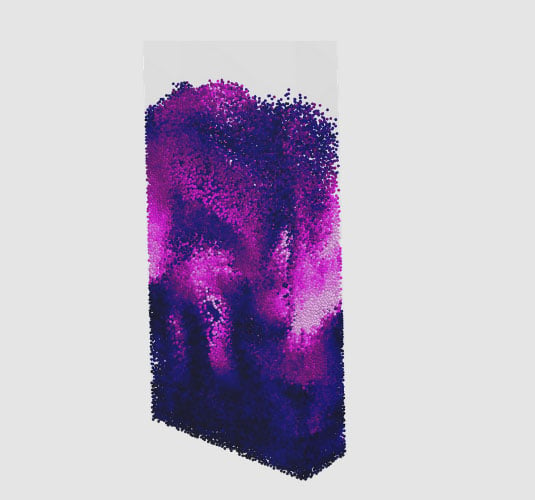

Fluidized Beds

Fluidized beds are commonplace in industry – particularly in chemical processing – and are used in a wide variety of processes such as freezing, cooling, heating, and coating. By coupling computational fluid dynamics (CFD) with discrete element modeling (DEM) using Altair CFD™ with EDEM companies can accurately simulate fluidized beds and other particle-fluid systems. DEM-CFD provides key information and can be used to assess the quality of fluidization and to understand mixing and segregation phenomena.

Conveying Equipment

Screw conveyors are frequently used in a range of industries to transport granular materials. With EDEM, companies can analyze the flow rate of different materials in the conveyor and get information on the forces and wear on equipment. EDEM can be used to predict any risk of blockages, assess the mixing and compression of the material, and obtain information on system capacity and power requirements.

Featured Resources

Guide to Process Manufacturing

Any industry that produces bulk quantities of goods such as pharmaceuticals, food, chemicals, or cosmetics, is seeking to produce these products consistently while reducing cost factors like waste and down time. Due to the nature of process manufacturing, multiple ingredients are combined to be mixed, coated, or sorted, so understanding the behavior of these processes is of paramount importance for manufacturers. Through the use of simulation modeling and Smart Manufacturing principals, manufacturers are now able to optimize these processes, leading to greater productivity and profitability.

Virtual Panel - Using the Discrete Element Method to Simulate Pharmaceutical Manufacturing Processes

Using EDEM at Astec, Inc.

Andrew Hobbs, Chief DEM/CFD Engineer at Astec, Inc. shares his experience using EDEM software. Astec is a global leader in the hot mix asphalt plant industry and Andrew's main focus in on applying fluid and particle simulation to better understand and improve hot mix asphalt equipment design.

In this video he discusses what key applications he uses EDEM for, the key benefits Astec gets from it as well as his thoughts on the future of simulation.

Go With the Flow: When DEM Meets CFD

Experimentations on multiphase flow systems are of crucial importance in research and engineering. However, they are lengthy, expensive, tedious and challenging. In many cases, it is not possible to conduct experiments on the micro and meso scales and that is why most industrial processes fail at the early stages of development, design and operation. With the constant evolution of efficient computational tools, we now can analyze these issues and provide solutions. CFD-DEM has found a wide range of applications in nearly all systems dealing with solids of various fields of science, engineering and technology such as chemical, food, pharmaceutical, biochemical, mechanical, energy, material and mineral engineering. The concepts of CFD and DEM are introduced along with their coupling. The commercial tools - EDEM (DEM) and AcuSolve (CFD) are reviewed and their key features are detailed.

Presented as part of the virtual ATCx DEM in November 2022.

Speaker: Jerrin Job Sibychan, Application Engineer, Altair

Duration: 15 minutes