Digital Solutions for Small and Medium Businesses (SMBs)

We know that small and medium businesses (SMBs) face a lot of daunting challenges in today’s hypercompetitive world. With disruptions such as inflation, continued supply chain hurdles, sustainability targets, talent acquisition and retention challenges,

time to market pressures, and more, SMBs face a myriad of challenges that test their resolve.

Altair and our channel partners understand these challenges and help SMBs achieve their goals with world-class technology, a wealth of experience

and expertise, and a dedicated approach that makes sure all our customers have the tools they need to make an impact. If you’re a brand-new startup or an established mid-size organization wanting to stay ahead of current and future product development trends, Altair’s unmatched portfolio

of simulation, artificial intelligence (AI), data analytics, and high-performance computing (HPC) solutions gives you the resources your growing organization needs to succeed.

Accelerate Simulation-driven Design

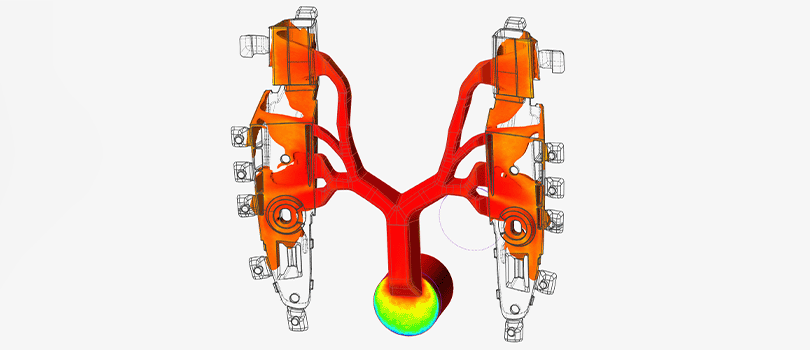

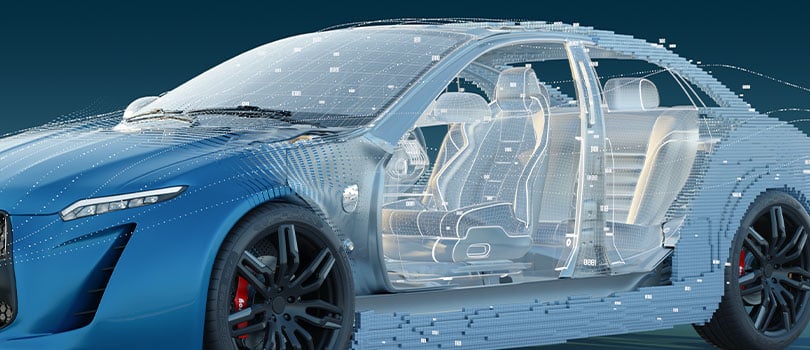

Altair knows digital transformation for small business like nobody else. Our simulation-driven design solutions changed product development forever, enabling engineers to reduce design iterations, minimize prototype testing, optimize designs,

enable lightweighting, and provide unmatched multiphysics solutions.

Today, Altair helps SMBs simulate at the speed of design with leading simulation tools like Altair® Inspire™, Altair SimSolid®,

Altair® SimLab®, and Altair® HyperWorks®.

With Altair’s multidisciplinary optimization and scalable HPC, you can solve real-world engineering problems quickly and effectively.

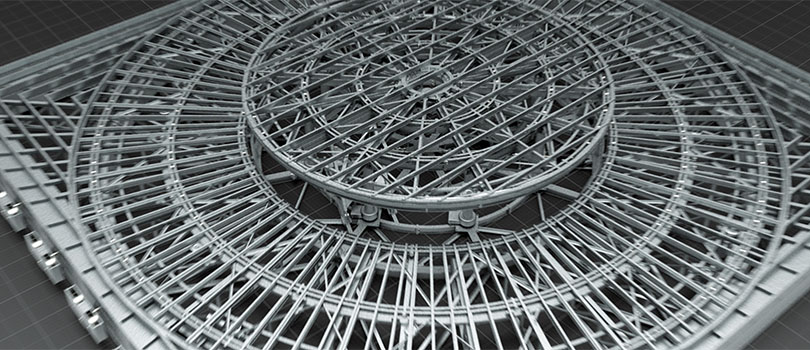

Design for Manufacturability

Connect and increase efficiencies and manufacturability with Altair’s solutions. We offer a unique set of simulation tools to evaluate product feasibility, optimize the manufacturing process, and run virtual try-outs for many traditional, subtractive, and additive manufacturing processes. With simulation, users can validate designs early in the manufacturing process and use optimization technology with specific manufacturing constraints to design better, more efficient products.

Operationalize Your Data

Altair’s data analytics solutions allow SMBs to harness data like never before in an intuitive, connected environment. Altair enables data-driven enterprises by providing SMBs with the power to use data analytics and AI solutions like Altair® RapidMiner®, to gain competitive advantages and drive next-level business results. Tools like Altair® Monarch® can help SMB finance departments connect, cleanse, and operationalize data with more than 80 pre-built data preparation functions and other advanced capabilities.

Solutions for SMB Organizations

To configure your preferred Altair suite, please visit altairone.com/marketplace.

Simulation-driven Design

The combination of physics-based simulation-driven design with machine learning – powered by the latest HPC technology – enables SMBs to explore and identify high-potential designs while rejecting low-potential concepts early in development cycles. Whether big or small, our SMB customers trust their decision-making to Altair, the pioneer of simulation-driven design.

Performance Analysis and Validation

Altair offers industry-leading tools that address structures, thermal, and fluid dynamics. Whether you’re an analyst performing finite element analysis (FEA) or computational fluid dynamics (CFD) modeling – or a design engineer who needs to understand the structural, fluid, and/or thermal effects on a design proposal – Altair has the tools for the job. Altair offers a comprehensive portfolio covering processes ranging from optimization tools to simulation-driven design concepts to detailed virtual product validation and simplified modeling workflows, advanced high-fidelity model building, and beyond.

Electronic System Design (ESD)

Altair’s simulation-driven ESD tools enable your team of specialized engineers to collaborate across all aspects of printed circuit board development from concept to manufacturing. Our products streamline your process, eliminate design iterations, and reduce time to market.

Data Analytics

Altair enables data-driven small and medium-sized enterprises by providing teams the power to use data analytics and AI to gain competitive advantages and drive next-level business results. Data isn’t just for the world’s largest organizations – with Altair, any SMB can take their data to the next level.

Altair works with channel partners worldwide.

Learn MoreWho We Serve

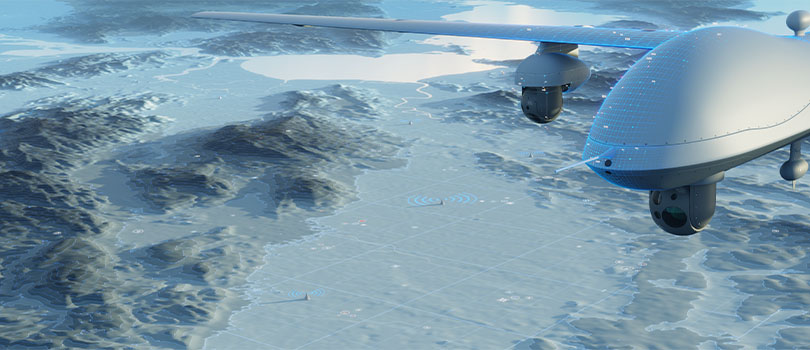

We work with SMBs in any industry. Click here to see where Altair products are making a difference.Aerospace and Defense

The aerospace and defense industry is a highly complex and demanding field, where safety, security, and sustainability are of utmost importance. Altair is at the forefront of addressing these issues. As new challenges and opportunities arise in areas like power system design, electrification, and supply chain management and manufacturing, Altair leverages its expertise in simulation, HPC, and AI to help organizations navigate this evolving landscape.

Automotive

Architecture, Engineering, and Construction (AEC)

To meet the global demand for more sustainable, more sophisticated structures – be they super-tall buildings, protective designs, industrial structures, factories, warehousing, transport infrastructure, communication towers or free-form façade systems – the construction industry is in a transformative period. When designing and building the world’s most innovative structures, teams can solve these challenges and more with Altair’s world-class design solutions. By modeling and predicting complex structural behavior, wind-induced actions, seismic responses, and other performance factors, Altair’s solutions optimize your structure’s performance, mitigate design risks, and ensure you meet code, safety, deadline, and cost specifications.

Technology

Watch the highlights from this year's “Simulate at the Speed of Design” event.

Watch NowAdditional Resources

Featured Resources

Predicting Product Quality at TEN TECH AERO

TEN TECH AEROSPACE & DEFENSE, INC. provides multi-discipline engineering services including high-end mechanical engineering design, analysis, physical testing support and hardware prototyping services.

Because speed and accuracy are top priorities, they selected Altair® SimLab® for its intuitive interface that allows them to stay in the same tool for the entire process from meshing and setup to solving and visualization. They are also able to use their legacy data efficiently, ensuring customers are fully protected.

Rolling Out a Better Process - Digital Twin Slashes Waste 15% and Runtime Hours to Seconds

Patrone and Mongiello wanted a solution to monitor and control its sheet metal forming process so that it could improve product quality and reduce production waste. The company selected Altair’s digital twin solution to achieve its goal and turned to Advanced Engineering (AE) Solutions, an Altair partner, to implement it. Altair’s digital twin solution gave Patrone and Mongiello the means to monitor quality and make corrections during all stages of its sheet metal forming process with respect to varying sheet metal material properties and equipment operating conditions. The digital twin solution, which leveraged Altair Inspire Form, Altair HyperStudy, Altair Activate, Altair romAI and Altair Panopticon, reduced production waste by more than 15%, reduced simulation time from hours to seconds, and enabled the company to monitor its forming process in a real-time environment.

The Way Forward to Improved Casting - Skaigh Engineering Uses Casting Simulation to Advance Process Development

Skaigh Engineering, based in Devon, U.K., specializes in high-quality aluminum gravity die castings for customers in various industries. To help its customers reduce development and manufacturing costs and grow in a highly competitive market, Skaigh set out to solve several typical problem areas such as wasted time spent improving customers’ poor manufacturing techniques and long lead times due to trial-and-error development methods involving inherited dies. Working with Origin Engineering Solutions, an Altair partner that provides design and simulation solutions, support, and training, Skaigh implemented Altair® Inspire™ Cast, which helped the company gain a better understanding of the casting process, let it try out theories without prototypes, and save money by reducing scrap and improving yields. In addition to producing an interface between product design and the casting process, simulation bridges skill and knowledge gaps and enables users to get things done right the first time.

Bringing Motor Control Design to Life at ZT Innovations

ZT Innovations is a motor control consulting firm that designs algorithms and software and hardware platforms. They pride themselves on their passion for motor control design as well as the out-of-box solutions they provide for products like electric bikes, medical drills, drones, compressors, and more. They found many software tools on the market were incomplete, requiring they employ multiple tools for different steps in the process that happened sequentially. As a result, their existing solutions needed significant simulation time to accurately represent the physical system and were extending overall time to completion for clients.

Altair® PSIM™ provides a complete solution for simulation of motor controls, microgrids, and power supplies that allowed them to run a full system simulation in a single step, rather than a linear process. PSIM shortens their simulation time exponentially, allows them to be a full-service provider and instills confidence in customers that their simulations realistically represent the actual system.