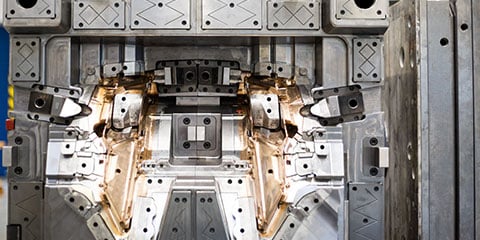

Altair® Inspire™ Mold

Injection Molding Simulation

Injection molding of plastics is an established, proven industrial manufacturing process for the mass production of identical components. Inspire Mold provides a modern integrated approach to streamline design for manufacturing (DfM) of injection molded components. Simulation is finally democratized and placed in the hands of designers and product engineers early in the development cycle, enabling easy exploration of options and delivering improved products, reduced scrap, and tooling rework costs.

Understand how the mold fills with a fast analysis, then dig deeper into the process with a detailed simulation of all the advanced physics.

Virtual testing, validation, correction, and optimization of molding designs can be easily performed through a five-step workflow, providing access to evaluation of injection molded part manufacturability that mitigates common manufacturing defects (warping, sink marks, short shots, etc.) long before a mold is made.

Altair offers a comprehensive set of solutions to develop innovative, manufacturable products faster: from the initial design of the part and understanding the injection molding process, to material mapping of reinforced engineering polymers and efficiently analyzing and optimizing the structural and fatigue performance of complex parts.