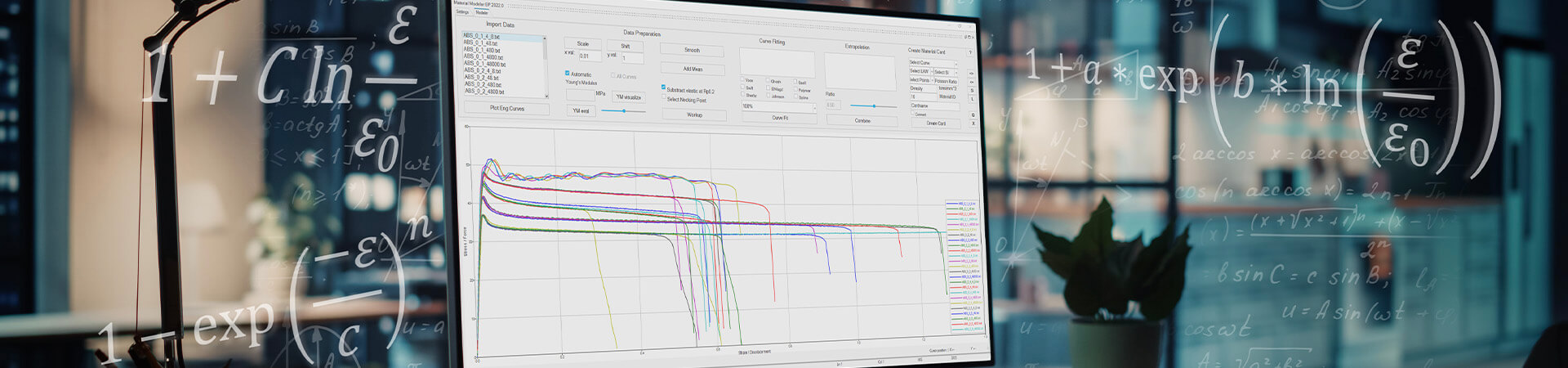

Altair® Material Modeler™

Comprehensive Multiphysics Material Modeling Framework

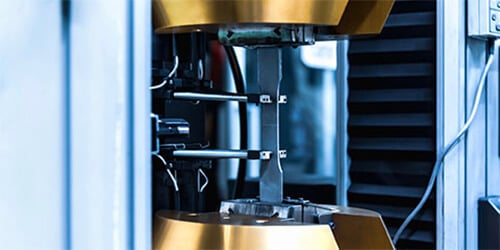

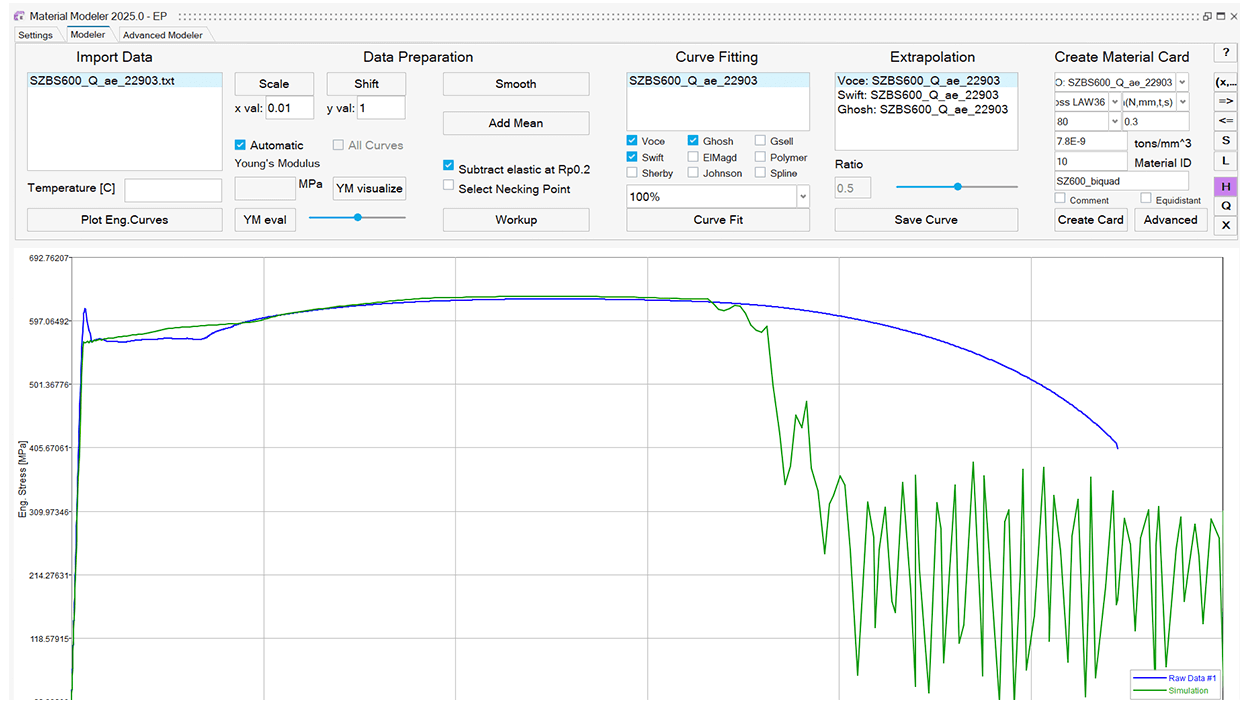

Accurate material modeling is key to performing reliable simulations, yet generating simulation-ready material data from raw test data can be time-consuming and inconsistent. To make well-informed decisions, high-quality material data is essential. Altair® Material Modeler™ is a modeling software that empowers users to efficiently process raw material test data and generate robust, simulation-ready material cards for an array of physics.

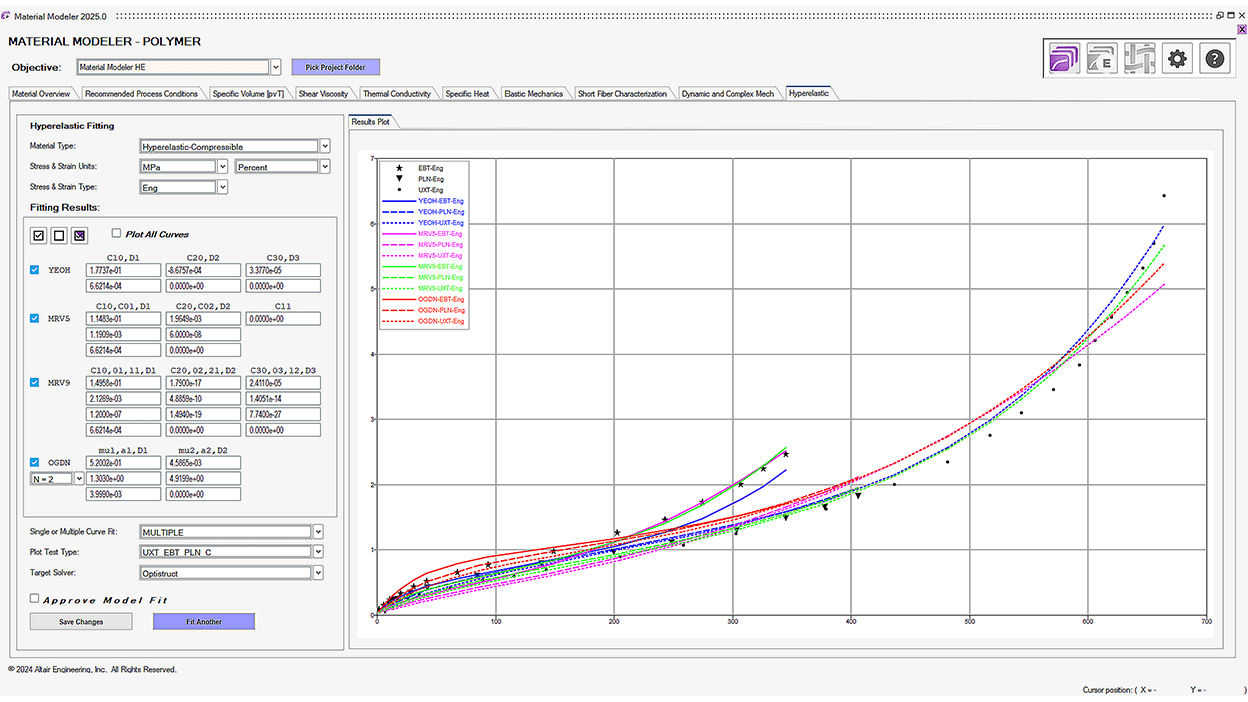

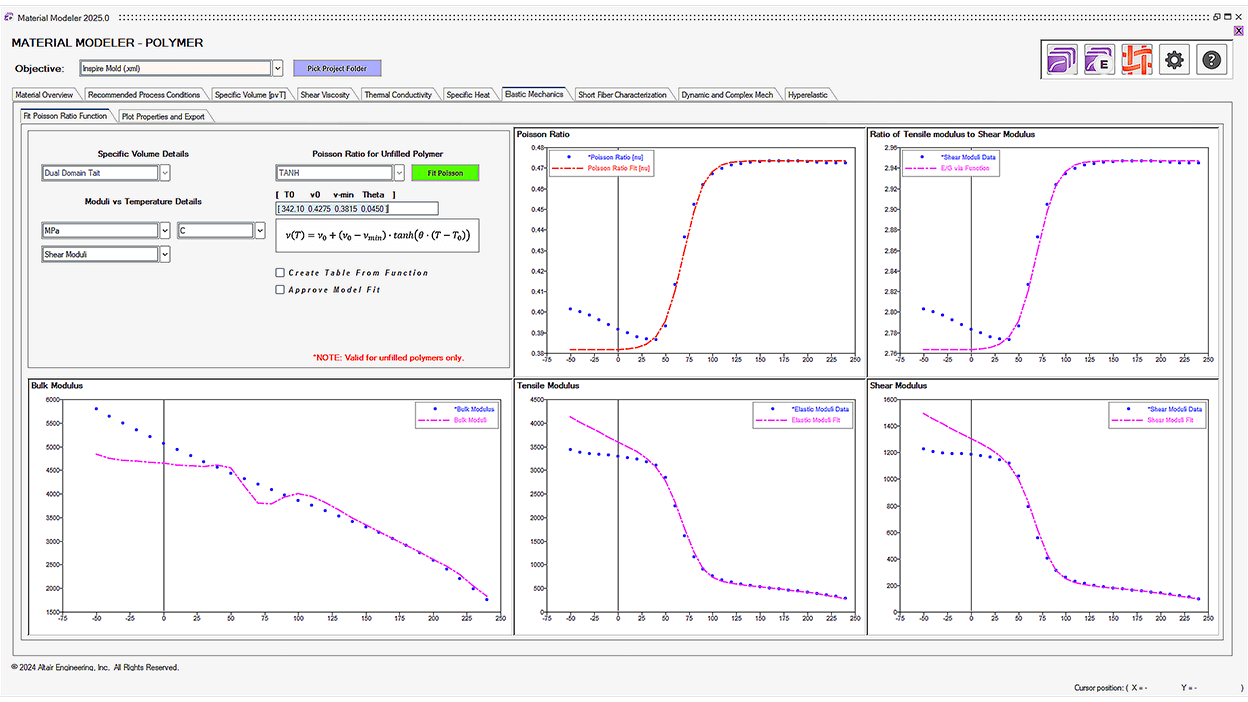

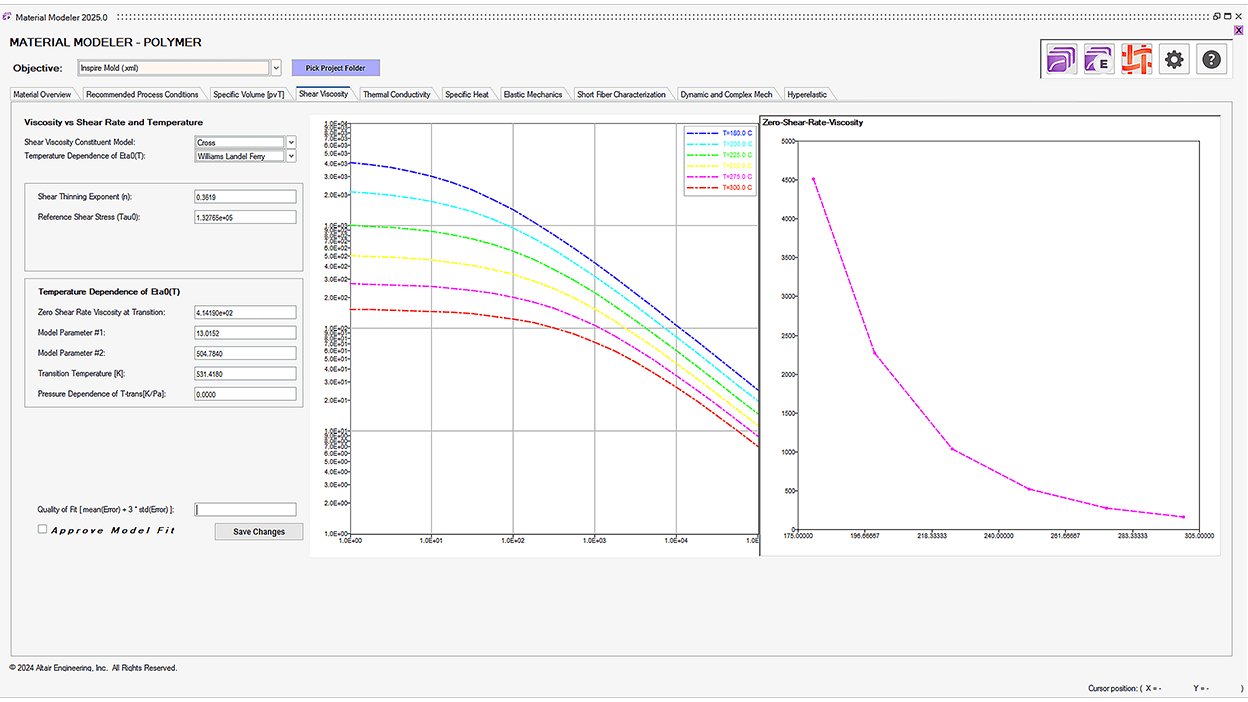

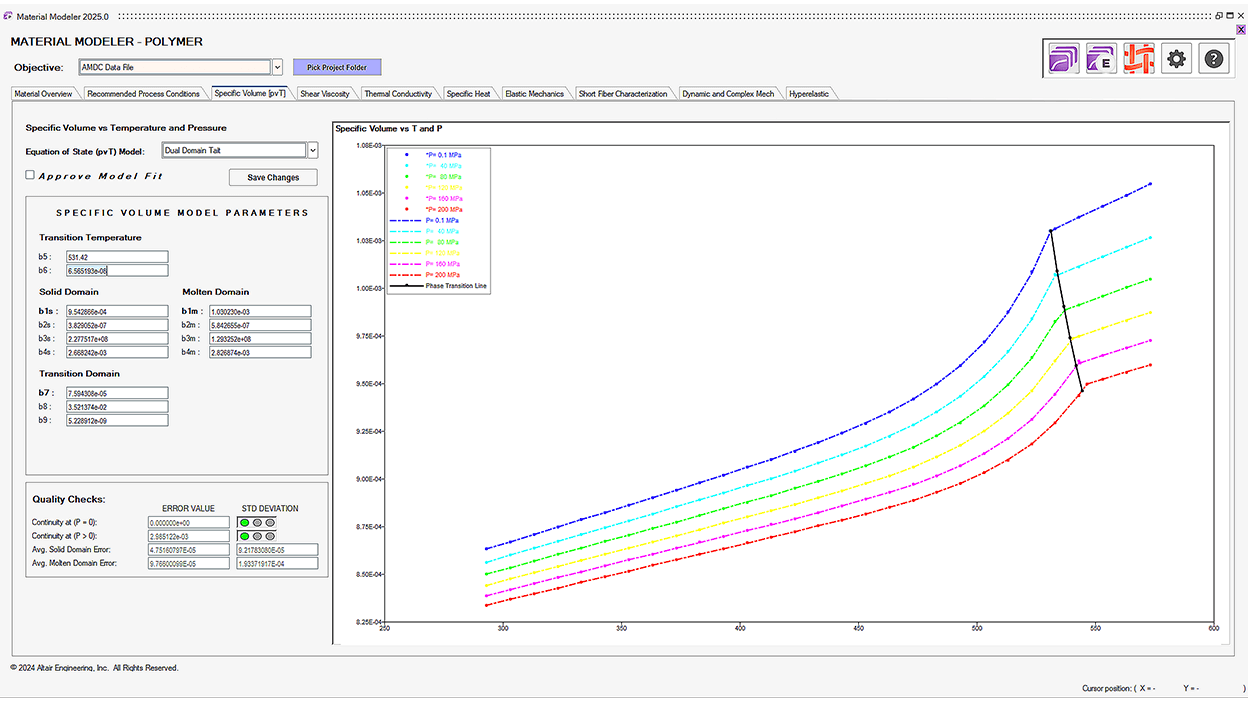

Automated, intuitive workflows let users create material data for thermomechanical, elasto-plastic, and hyperelastic material models in record time. Built-in tools enable virtual validations to ensure confidence in data. Seamlessly integrated with Altair®

Material Data Center™, users can access solver-neutral data from an extensive material library, refine and process within Material Modeler, and securely store data in a private organizational database. Simulation-ready material cards are generated

dynamically, delivering precise, application-specific data for various solvers – ultimately streamlining the design process.