Smart Manufacturing

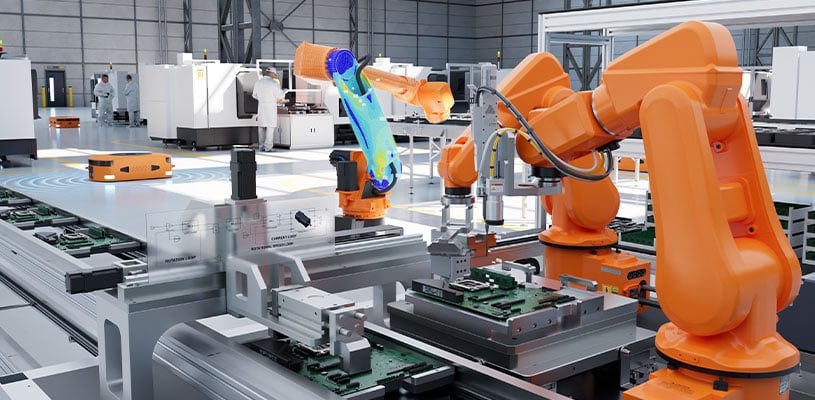

Altair’s software and cloud solutions power smart manufacturing by seamlessly integrating Industry 4.0 technologies, including Industrial Internet of Things (IIoT). We help manufacturers overcome key challenges—real-time data processing, production flexibility, and downtime reduction—through advanced simulation, data analytics and artificial intelligence (AI), and high-performance computing (HPC).

Our digital twin technology optimizes operations, while AI-driven analytics enhance predictive maintenance and efficiency. By enabling end-to-end digital transformation, we deliver the intelligence and computational power needed to maximize productivity and innovation across the entire supply chain.

Benefits of Altair’s Smart Manufacturing Technology

Production Quality and Yield Improvement

Predictive Maintenance and Asset Optimization

Operationalizing AI at Scale

Data Integration Across OT and IT Systems

Our Technology Partners

Generative AI on the Factory Floor

Build intelligent copilots and AI agents effortlessly with a code-optional interface that allows users to create advanced AI-driven solutions without extensive programming knowledge. Design and deploy these smart assistants to automate tasks, provide real-time support, and enhance operator experiences. Additionally, enable seamless interaction with complex documentation by querying it using natural language, making it easier to access and understand critical information quickly and efficiently.

Digital Twins

Digital twins optimize performance, improve in-service visibility, predict maintenance needs, and extend product life. Physics-based twins enhance insights, while real-time-compliant reduced-order models (ROMs) enable faster, more accurate decisions. By integrating AI, machine learning, and advanced analytics, digital twins also help detect inefficiencies, automate tasks, and simulate improvements without disrupting operations. Our complete, open, flexible approach empowers your digital transformation—enabling scalable, continuous optimization.

Quality Monitoring

In fast-paced manufacturing, even minor defects can lead to recalls, delays, and lost customer trust. Traditional quality checks are too slow and reactive to keep up. Altair’s smart manufacturing solutions provide real-time defect detection, advanced root cause analysis, and predictive insights that prevent scrap, rework, and downtime. From raw materials to finished goods, quality is always monitored, controlled, and improved—without disrupting your production flow.

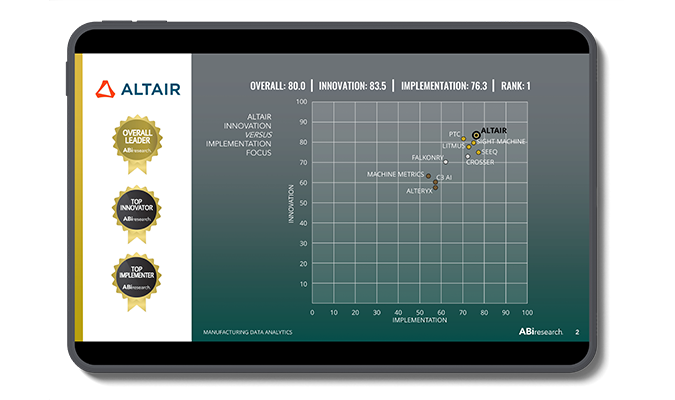

Manufacturing Analytics

IIoT is increasing connectivity, generating data, and unlocking potential. Altair takes full advantage of data and manufacturing analytics to fuel innovation, drive new opportunities, and accelerate your smart manufacturing transformation.

Process Optimization

Altair has pioneered simulation-driven design for manufacturing (SDfM), integrating fast solvers, intuitive interfaces, and predictive models into early concept design. This empowers engineers to explore while enabling real-time optimization and informed decision-making. By integrating automation, AI-driven efficiency, and digital twins, Altair enhances design quality and production performance.

Additive Manufacturing

Organizations are leveraging advanced solutions to design and optimize components for additive manufacturing. With Altair’s tools, designers can unlock the power of additive manufacturing, creating intricate, organic shapes that meet functional requirements—free from the constraints of traditional manufacturing methods.

Altair® AI Edge™

Deploy machine learning models to the edge with drag-and-drop operators—no complex coding required. Seamlessly integrate with the Altair® RapidMiner® platform to streamline AI workflows. Orchestrate hundreds of devices with advanced fleet management for real-time insights and optimal performance.

IoT Technology

Build smart, connected IoT projects with ease. Integrate and manage all your smart devices and sensors in a unified environment, enabling seamless communication, real-time data sharing, and enhanced automation. Unlock new possibilities with a scalable, flexible platform designed to power intelligent IoT solutions.

Master complex concepts with ease with our Blueprint series, a comprehensive learning initiative that simplifies technical concepts into easy-to-follow modules.

Featured Resources

Altair AI Edge: Scalable Solutions for Industrial Vision Use Cases

Altair AI Edge is a groundbreaking solution that enables engineers of all kinds – even those with little to no coding experience – to tackle complex industrial vision challenges. By using intuitive drag-and-drop workflows, engineers can easily design customized solutions and deploy them to a fleet of rugged, standalone, low-cost devices. These devices are equipped with secure, tightly integrated software, making it possible to implement solutions in any company plant with minimal effort and maximum efficiency.

Data-Driven Root Cause Analysis With Advanced Analytics and AI

In today's data-driven world, understanding and resolving problems efficiently is crucial for businesses across industries. Root cause analysis (RCA) is a systematic approach to identifying the underlying reasons behind issues and anomalies, helping organizations improve quality, optimize operations, and mitigate risks. While many companies already perform some form of RCA, leveraging advanced tools and methodologies can enhance the process.

This white paper explores key stages of RCA, discusses various analytical techniques, and highlights how data analytics and artificial intelligence (AI) platforms like Altair® RapidMiner® can drive more effective data-driven investigations.

Scissors to Streaming: AI-Driven Manufacturing Quality Revolution

A leading global specialty materials company is focused on filtration and advanced materials. Their expertise extends across water purification, HVAC and industrial air filtration, industrial packaging, cutting-edge extrusion nettings, and nonwoven coating technologies.

In this use case, we’ll explore the company’s challenges and how AI-driven solutions reduced startup downtime and waste, optimized operations, streamlined production processes, and helped them boost the efficiency of their manufacturing line.

AI Agents Powered by Altair RapidMiner

In today’s fast-paced world, organizations in every industry face countless challenges like operational inefficiencies, customer expectations, compliance, cost management, and beyond. Artificial intelligence (AI) agents can help organizations tackle these challenges head-on. By blending the power of AI and seamless integration into existing systems and processes, AI agents unlock a world of transformative change and sustainable growth.