A Digital Twin for Low-Risk Virtual Commissioning

With digital twins and system-level modeling tools, virtual commissioning is becoming an even more powerful technique in the Industry 4.0 toolbox.

Imagine a manufacturing system that, on first glance, might function like any other modern system. While seemingly ordinary, the automated machines in this system experience significantly less downtime than you’d expect. This is because each

machine is being operated alongside a virtual, real-time model that corresponds to all of the dynamics and components inside the real machine. Whenever the machine might be close to malfunctioning, the virtual model is two steps ahead, either

making slight adjustments to its controllers, or notifying a maintenance staff before the issue causes downtime.

This approach to modern, efficient machine design is quickly becoming a key technology for reducing costs and ensuring smarter products. The technology behind this process uses what Industry 4.0 is calling a digital twin, and by using modern system-level modeling tools, they are becoming an important part of the virtual commissioning process.

For those who are just getting started, a digital twin

is a dynamic, virtual representation of a corresponding physical product. These models can range widely in their purpose and fidelity, but they serve as a powerful connection to the product for diagnostics, design changes, and an important new process

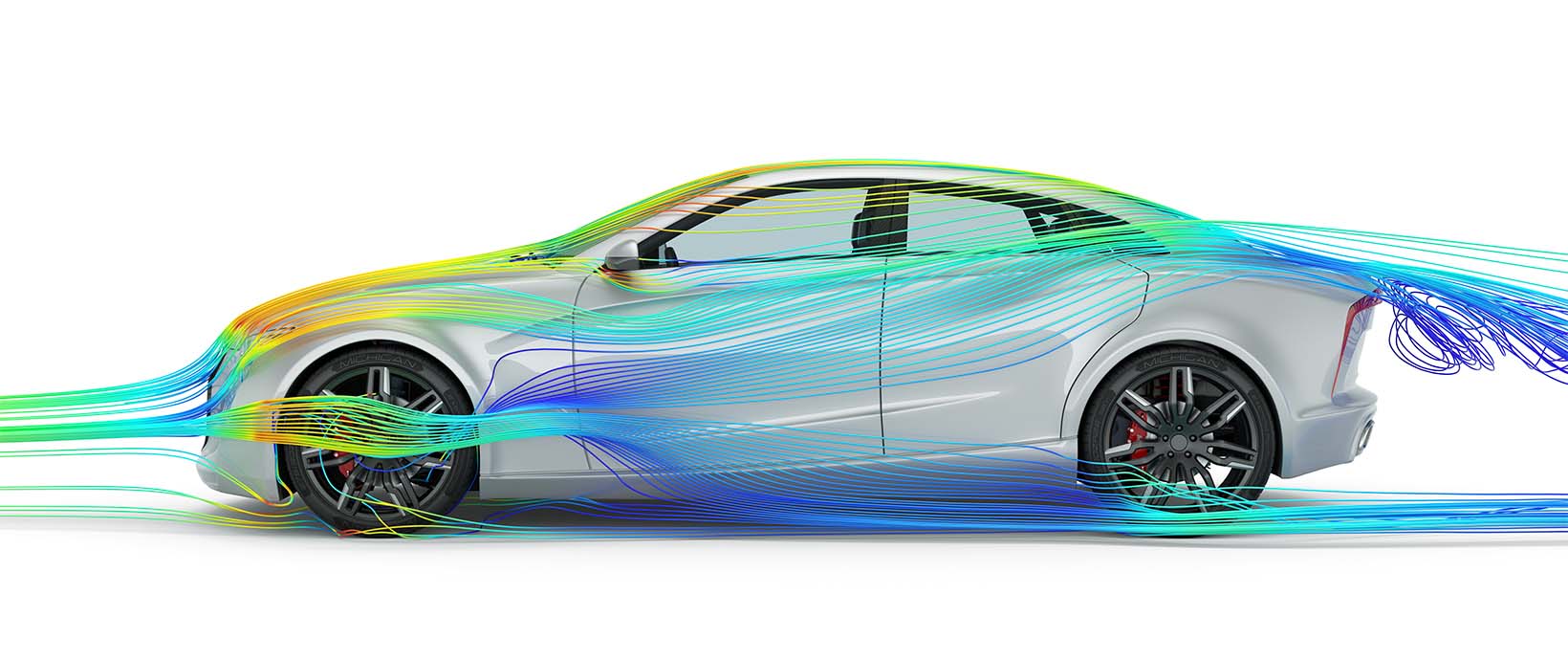

called virtual commissioning. Companies are using digital twins across industries, allowing them to optimize their products in ways that were previously impossible.

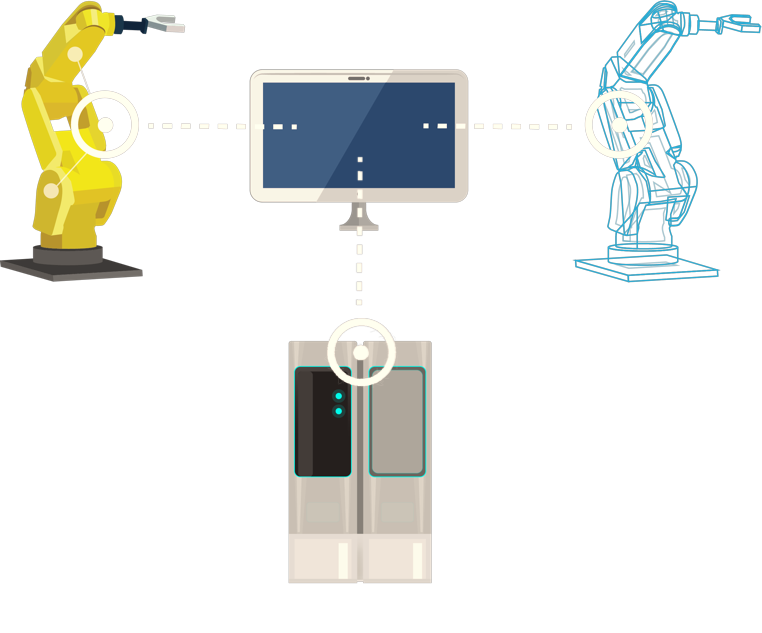

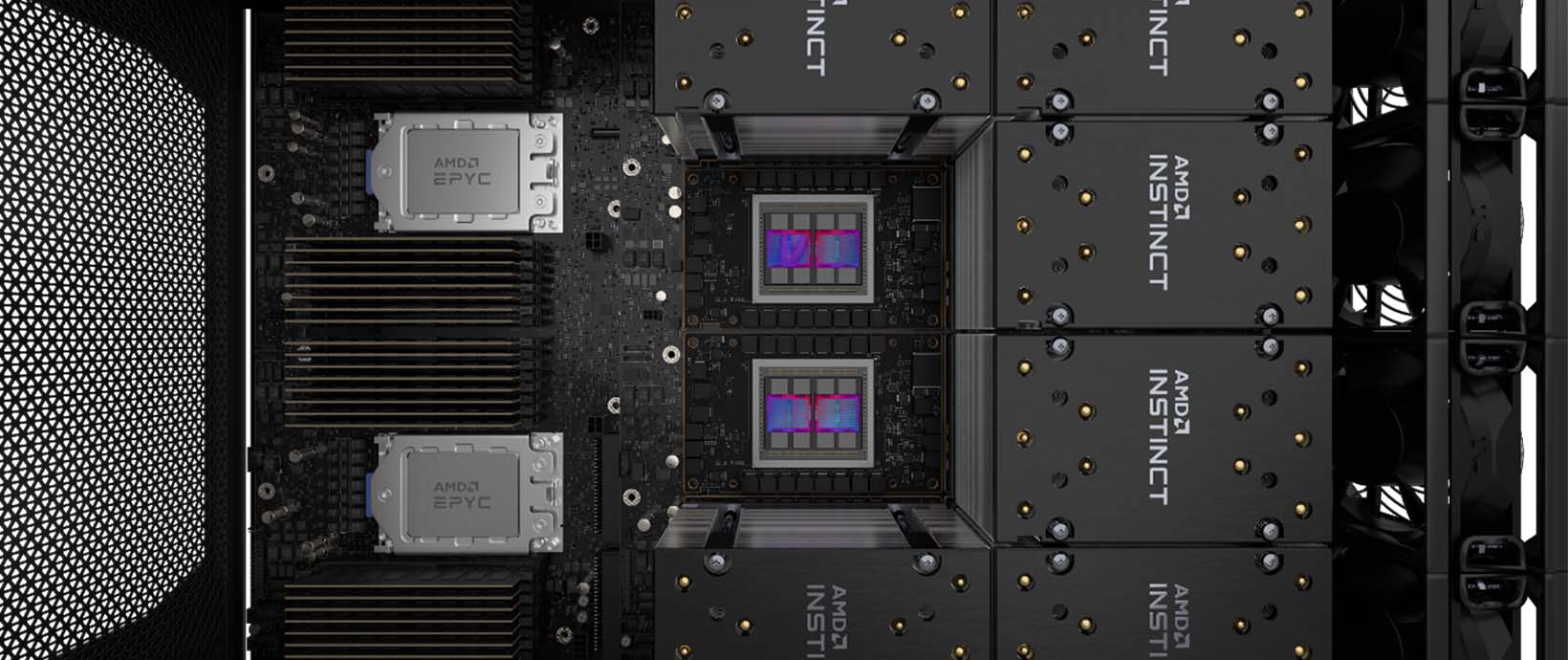

Figure 1: With the advent of digital twins and common integration standards, virtual models can connect with virtual control code, PLC hardware, and even the physical product itself

Initially, digital twins were typically created once the physical product was in operation. Using vast amounts of data from sensors on the product, predictive models could be created to assist with diagnostics and improvements. By using a system-level modeling tool like MapleSim, the creation of a model-driven digital twin can begin alongside the design process. Meaningful digital twins can be created before a physical product is finalized, allowing for a powerful test platform to validate product performance earlier than ever.

A key technology ushered in by Industry 4.0 is the process of virtual commissioning. This technology is addressing the most common pains faced by engineers during the system integration phase of their product design. Often, the commissioning phase of product design is one of the most uncertain and expensive phases. When it’s time to bring together all of the hardware and the programmable logic controllers (PLC), there are often a variety of bugs and design kinks that need to be worked out. Companies are often forced to resolve these issues on tight deadlines, lest they delay their project and risk both their reputation and their bottom line.

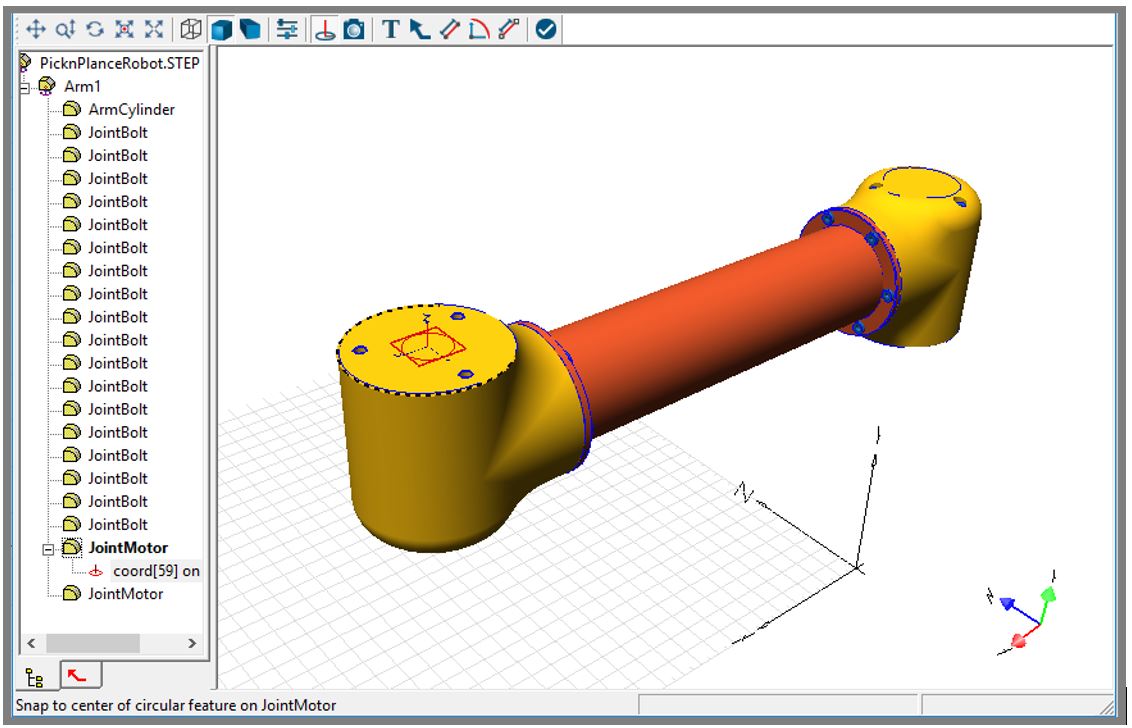

During virtual commissioning, engineers can import their CAD designs directly into a tool like MapleSim, and create a high-fidelity model of their system dynamics. This model gives the engineer new abilities to get quick insight into system integrations issues, long before the expensive commissioning stage. They can import their motor parameters, define their product’s motion profiles, and have easy access to a full set of results after simulation.

Now, the engineer is ready to move to the key process of virtual commissioning. They can export their MapleSim model to the industry-standard Functional Mock-up Interface (FMI), and connect it to standard automation tools for virtual integration testing. With the digital twin model and the PLC design in the same environment, it’s now possible to test for integration issues long before the physical commissioning is required. The PLC systems are tested against a high-fidelity, functional model of the physical product, giving engineers a much clearer expectation of how their automated designs will perform after physical deployment. Every issue caught at the virtual commissioning stage then becomes one less unexpected issue that might crop up during physical commissioning. Catching even a handful of issues early can often save companies huge amounts of time and money, as fixing issues on a virtual platform is far easier than revising physical products.

The power of model-driven digital twins doesn’t end with virtual commissioning. By having a high-fidelity model paired with the physical product, there are benefits along the entire design process – even after the commissioning process itself.

Companies who have adopted model-driven practices with digital twins are using these models throughout the operation of their machines. They use them for real-time diagnostics, as the inline digital twins can provide information about torques, inertias,

and more. This helps ensure less downtime, as issues can be spotted early and fixed faster. Many companies also experience the cost-savings of using a digital twin, as the high-fidelity model can give them much of the information that they’d

previously need to obtain from expensive physical sensors.

The increasing utility of model-driven digital twins is fast cementing them as a necessary technology for Industry 4.0. While digital twins seem to offer incredible insight at many stages

along the design process, they can still be met with hesitation. The adoption of digital twin-driven design techniques like virtual commissioning calls for changes to an engineer’s design process. Often, it can feel as if the promises of digital

twins are too good to be true, and the path forward is unclear.

To overcome these barriers, many companies undergo a pilot project in partnership with their digital twin tool vendor. Using a tool like MapleSim, companies will work with the vendor to create the digital twin, ensure it connects to their automation software,

and provide training at each step of the way. This process can help a company see success with a single project, and give them the internal skills to build digital twins into other products at their own pace.

As the cycle of innovation quickens,

digital twins are becoming increasingly popular across industries to reduce risks and get new products to market faster. With a growing Industry 4.0, and advanced modeling tools, model-driven digital twins are securing their place as an essential

component for the modern design process.

This post is a guest contribution from Altair Partner Alliance member Maplesoft, written by Chad Schmitke, Senior Director of Product Development and Graham Jackson, Engineering Specialist.