Simulation-Driven Design with Altair® HyperWorks® is a Slam Dunk

Basketball season is upon us, with teams and fans alike filled with boundless optimism for their chances of achieving great things this season. Players are grinding their game and putting in extra work to perfect their craft as the season wears on. If your neighborhood is fairly typical, you’re likely to see that seemingly every other house has a portable basketball hoop pulled out into the street, replete with players heaving up 3-pointers from all directions. As any neighborhood basketball player can attest, not all portable hoops are built equally. Some are much too flimsy, with a forgiving rim that helps almost any shot go in. On the other hand, some hoops send the slightest miss flying into adjacent driveways. Ideally, you want a hoop that replicates the ones the finest collegiate and professional players use.

But such a task is much easier said than done. For a design that meets this criteria, some hoops can cost more than $3,000. Ones in lower price ranges can be very hit or miss. Thankfully, with the Altair® HyperWorks® design and simulation platform, we can design our own hoop and bypass this frustrating, but all-important choice.

Setting the Criteria

First, we need to define the design criteria for the system. Below is the list our team devised, along with what these characteristics entail:

- Rim height adjustability: Users must be able to easily and safely vary the rim height from 7 to 10 feet to permit various ages and skill levels to enjoy the system.

- Playability: Structure should have the right amount of stiffness so the ball plays off the rim and backboard properly. Structure’s mass distribution should keep the system stable and grounded.

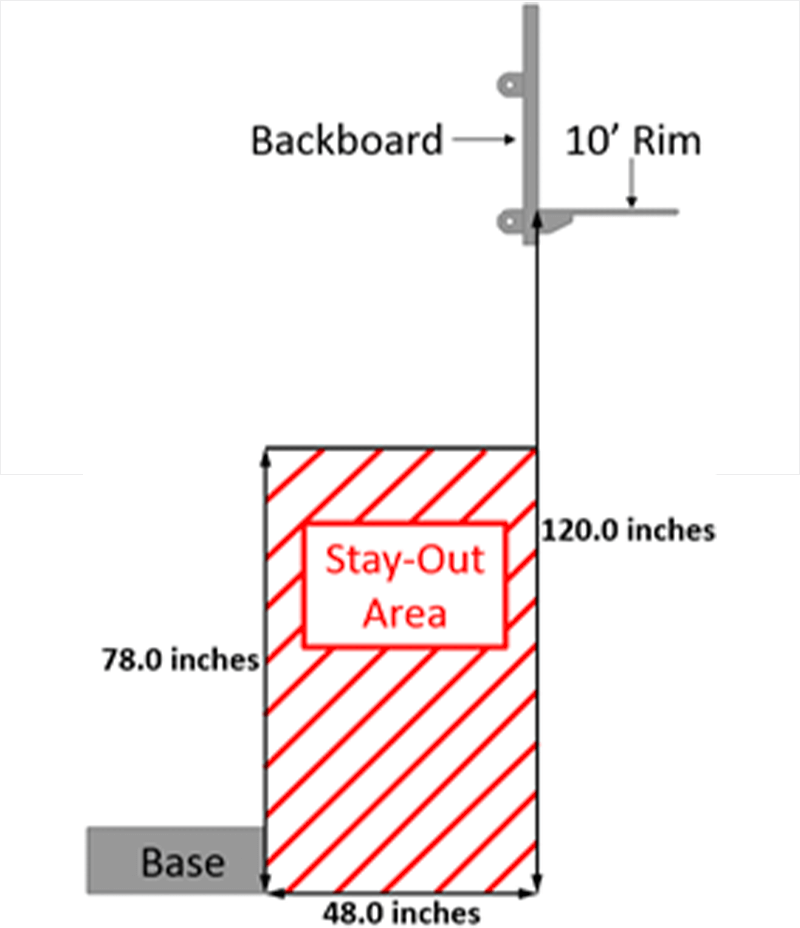

- Safety: Distance from the plane of the backboard to the base and structure should be 48x78 inches; center of gravity should be as low and as far away from the rim as possible.

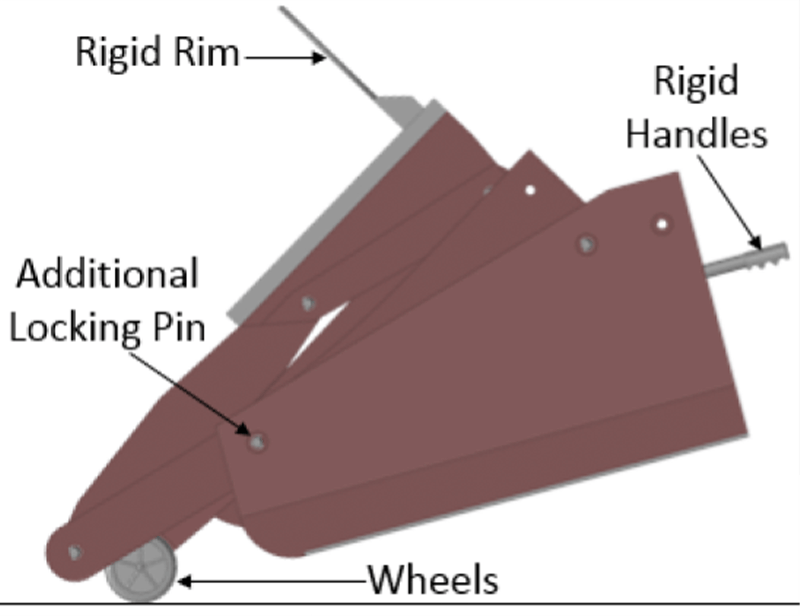

- Compactness and portability: Users should be able to fold the structure to fit into a standard garage door (84 inches high) and it should be easy to position in different locations.

- Durability: Structure should last between 8-10 years and be able to withstand an array of outdoor conditions (sun exposure, rain, snow, wind, etc.).

- Affordability: Must utilize inexpensive manufacturing, materials, and standard off-the-shelf products to minimize material use and cost.

- Assembly and manufacturability: Must be easy to properly assemble for users and easy to make for manufacturers.

Designing the Hoop

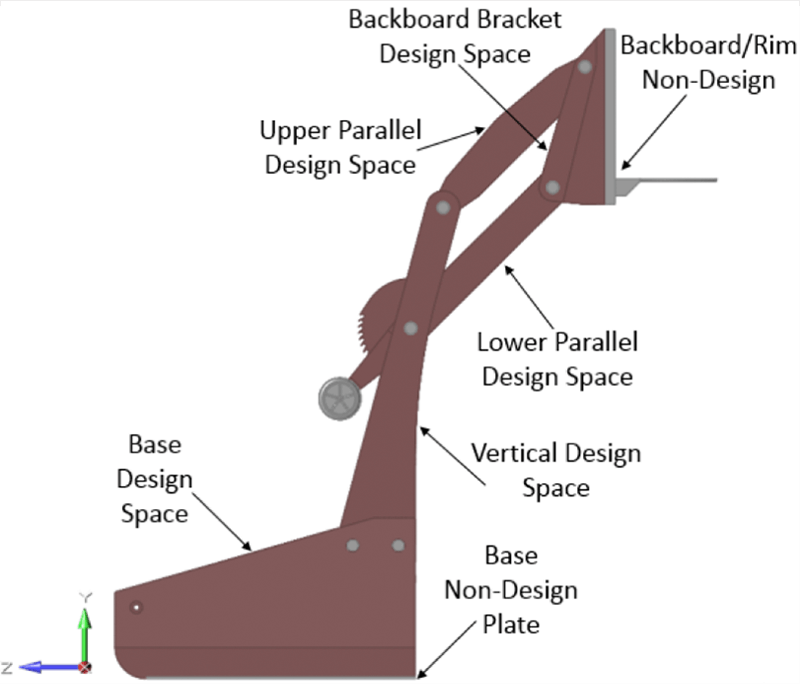

Since these are the initial steps in the simulation-driven design process, we didn’t attempt to meet all the design goals in this first stage. Our main focus was on the mechanism, structure, and mass distribution. Cost and manufacturing were considered but weren’t yet driving the design at this point.

There were several challenges to tackle with this system that we categorized into three main buckets: geometrical, structural, and analytical. Early steps address several of the geometrical challenges and many of the design goals were achieved through careful geometrical design of the structure and mechanism. This included creating a mechanism which keeps the backboard perpendicular to the ground at any height; folding the assembly into a compact structure small enough to fit in a standard garage; and maintaining the 48x78 inch “stay-out” area. Altair® Inspire™ has intuitive geometry creation tools and Altair Inspire Motion has motion simulation technology to visualize the kinematics. These were the perfect tools to quickly mock up designs, evaluate motion, and troubleshoot.

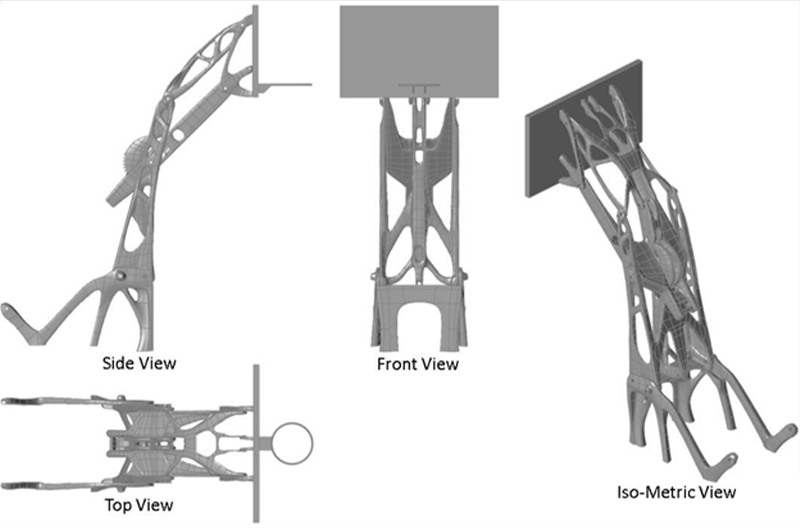

Once the layout of the mechanical system was complete, the focus turned to the structural challenges. These included ensuring the hoop was sufficiently stiff, minimizing the amount of material, and making it strong enough to withstand common wear and tear. These challenges inherently clashed with each other. Typically, a structure with more material is stiffer and stronger, meaning minimizing the amount of material used would (generally) make it weaker and less stiff. The key is to put material only in the necessary places to support the expected loads the system will experience throughout its life cycle. It can be tricky to find these locations – but luckily, our team didn’t have to guess because Altair® OptiStruct® did it for us.

The last set of challenges were the analytical challenges. This difficulty occurred because the assembly experiences various loads in several different configurations. Typically in finite element (FE) analysis, one configuration is analyzed and optimized at a time. To optimize the structure, all load cases in all configurations needed to be considered simultaneously during the topology optimization. This required at least five different FE models to evaluate the five different configurations (7 feet, 8 feet, 9 feet, 10 feet, folded) and load cases. During the topology optimization, the five models were analyzed concurrently to determine optimal material placement. With OptiStruct’s multi-model optimization (MMO) this was possible with very little effort.

We think this design is progressing well, but still has some work to do if we want to accomplish all our design goals. The next steps will include pinpointing which materials work best for the different components, identifying what manufacturing methods make the most sense, and continuing to optimize stability and performance. Simulation-driven design with Altair HyperWorks accelerates the design process and produces better products. This basketball hoop is a fun example of how simulation-driven design can be applied, but this same process could be applied to countless other products and structures. Using simulation to speed up the design cycle, troubleshoot and visualize the mechanisms, and optimize structural components are just a few of Altair HyperWorks’ many capabilities.