Efficient Use of Resources in Manufacture of Metal Components

In the newly opened 3D-Printing Lab for Metals and Structural Materials at the Fraunhofer Institute for High-Speed Dynamics, Ernst-Mach-Institut, EMI, researchers have investigated how resource- efficient an Additive Manufacturing process is when lightweight aluminum components are manufactured using additive methods. They discovered that even marginal reductions in the material and resources used per component yield high cost savings in series manufacturing.

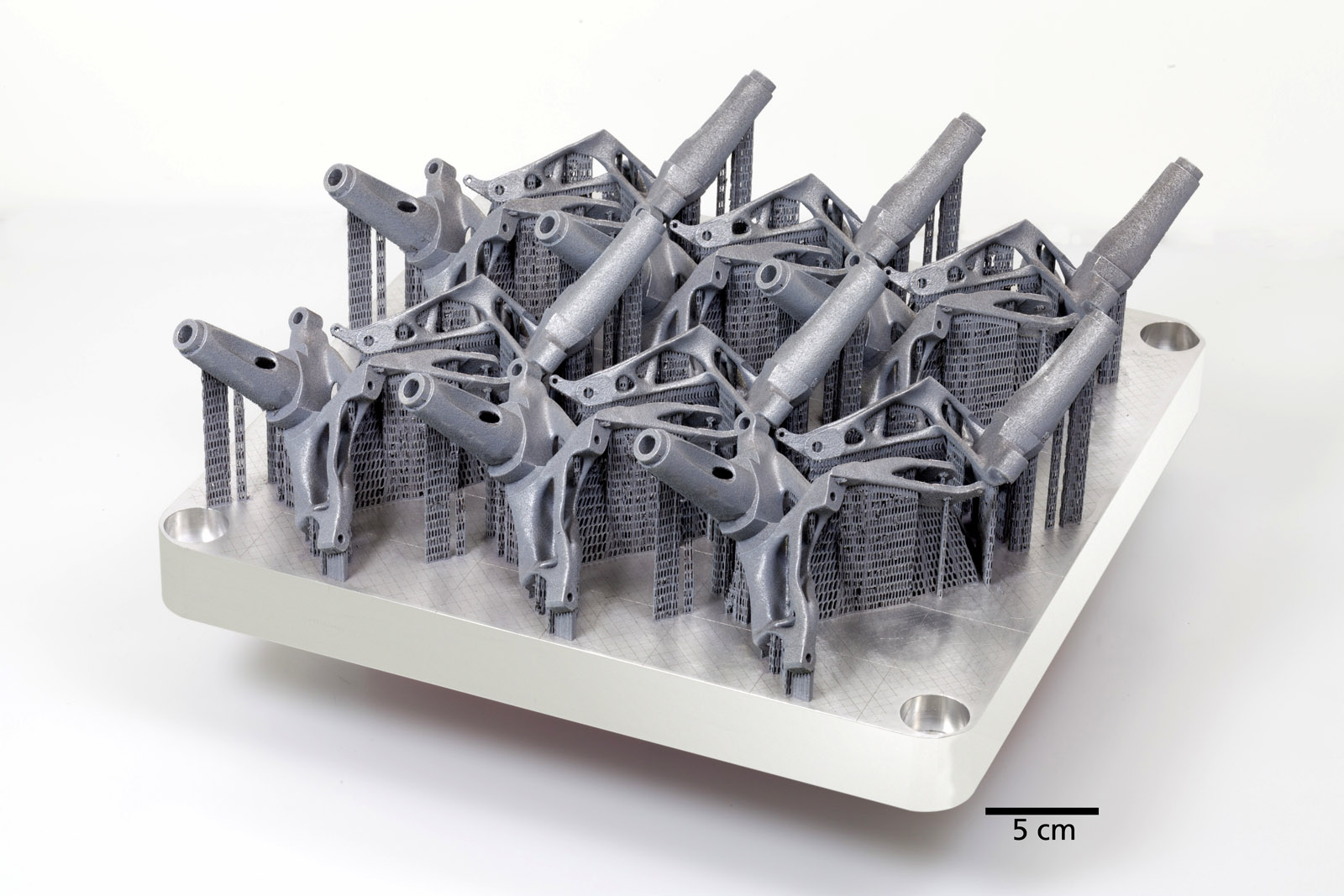

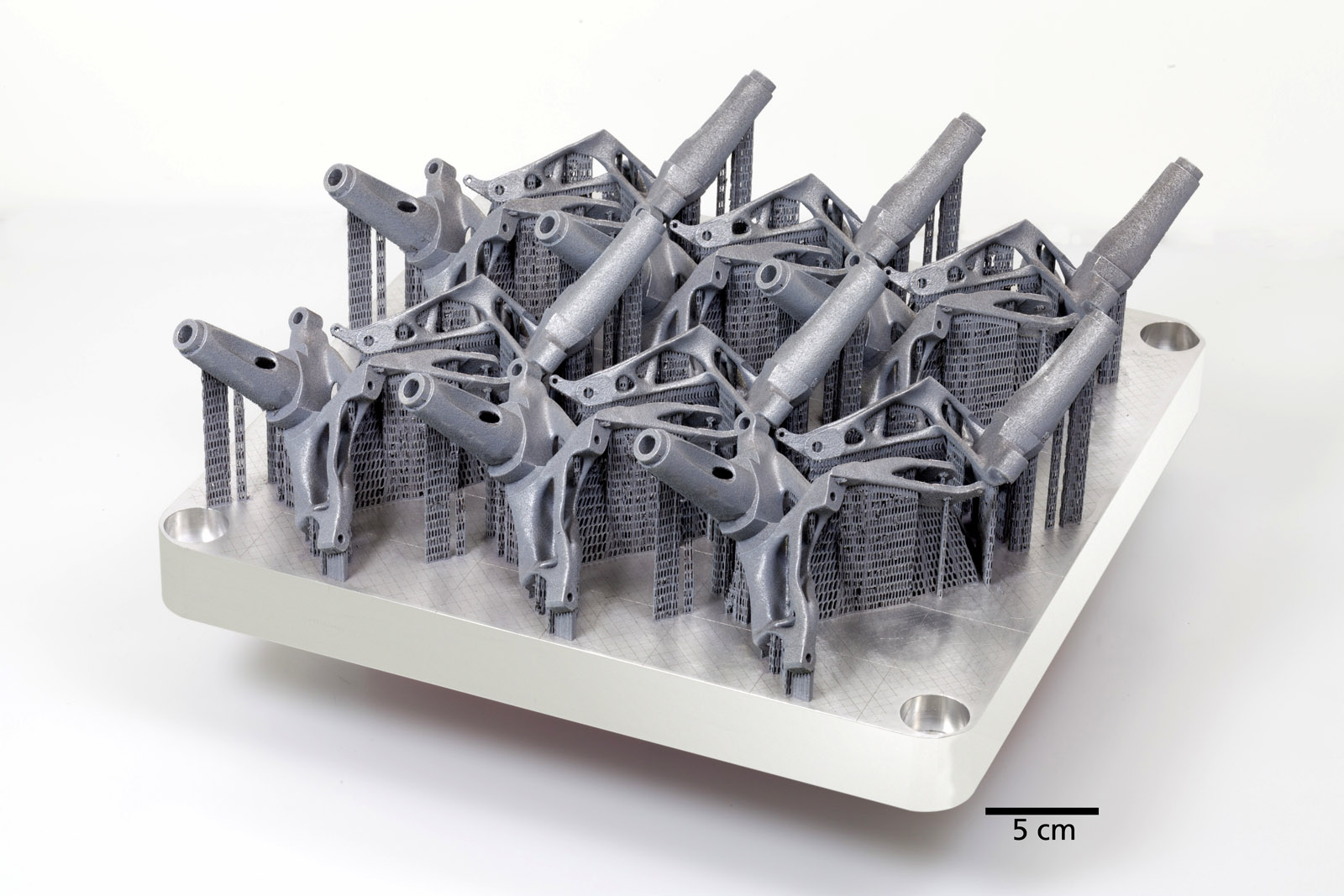

The 3D-Printing Lab for Metals and Structural Materials at Fraunhofer EMI in Freiburg houses one of the largest commercially available 3D printers for metal currently in existence. In the research sector, an apparatus of this size is unique. Using the selective laser melting technique, metal structures with dimensions of up to 40 centimeters can be made by additive manufacturing. 3D printing offers completely new ways of designing components with highly complex shapes and optimizing their weight.

But it is only by combining Additive Manufacturing and intelligent lightweight design that you can maximize resource efficiency in manufacturing. Fraunhofer researchers in the 3D-Printing Lab have investigated just how economical the manufacturing process is in terms of resources, and whether material and operating costs can be minimized compared to conventional industrial methods. To do this, they took a practical, widespread component for their tests: a wheel carrier such as might be used in a lightweight vehicle. “We were able to quantify the effect lightweight construction – and specifically the use of structural optimization methods – has on the resources used in the SLM manufacturing process,” says Klaus Hoschke, scientist and group leader at Fraunhofer EMI. The focus was on energy and material consumption, the manufacturing time and the CO2 emissions that arise during the small-scale production of twelve wheel bearings.

After the researchers had used the numerical finite element method (FEM) to simulate and analyze a draft design and determine the right geometric shape with structural optimization methods, they constructed the wheel bearing in an optimized lightweight design. The result was a wheel bearing designed for the defined load scenarios and offering maximum performance. Because of their geometric complexity, structures produced in this way cannot be manufactured by conventional methods such as milling or turning. “With the lighter model, we were able to save hugely on resources during production, as less material has to be produced per component. If you multiply this by the number of units in a small-scale run, then you require less time, material and energy for manufacturing. Reducing volume through the use of higher-strength materials offers the greatest potential for energy savings here,” says the researcher. Using the numerically optimized version of the wheel bearing, 15 percent less energy was required for the additive process than for the conventional method: Twelve kilowatt hours of electricity were needed for the conventional design, whereas only ten kilowatt hours were needed for the numerically optimized design. (In each case, the measured value refers to a series-manufactured component.) Manufacturing time was cut by 14 percent and CO2 emissions by 19 percent. And where material consumption was concerned, it could be significantly reduced by 28 percent.

Although structure-optimizing algorithms and numerical optimization simulations are already being employed in the 3D printing of components today, they are only used when the component must be extremely lightweight, such as aircraft parts designed to reduce fuel consumption during operation. Components that lack these implications as regards structural optimization are still generally manufactured using conventional industrial methods. The results of the small-scale series production of the wheel bearing suggest that additive manufacturing can also be useful when a component does not have to be structurally optimized as such. “A heat exchanger or a tool mold, for example, do not have to be lightweight to improve their functionality. Nevertheless, it makes sense to design them with reduced weight and volume when manufacturing them additively, because this way you can bring down manufacturing costs,” explains Hoschke.

Forecasts on what effect the Additive Manufacturing of metals will have on global production vary widely. But everyone agrees on one thing: for many industries – such as aerospace, automotive engineering, medical engineering and toolmaking – it is a game changer. “Our positive results for resource efficiency in the manufacturing process should reinforce this,” says the scientist. In the future, Hoschke and his team want to research the extent to which other design heights, series sizes and materials such as titanium affect the resource efficiency of the manufacturing process.

The 3D-Printing Lab for Metals and Structural Materials at Fraunhofer EMI in Freiburg houses one of the largest commercially available 3D printers for metal currently in existence. In the research sector, an apparatus of this size is unique. Using the selective laser melting technique, metal structures with dimensions of up to 40 centimeters can be made by additive manufacturing. 3D printing offers completely new ways of designing components with highly complex shapes and optimizing their weight.

But it is only by combining Additive Manufacturing and intelligent lightweight design that you can maximize resource efficiency in manufacturing. Fraunhofer researchers in the 3D-Printing Lab have investigated just how economical the manufacturing process is in terms of resources, and whether material and operating costs can be minimized compared to conventional industrial methods. To do this, they took a practical, widespread component for their tests: a wheel carrier such as might be used in a lightweight vehicle. “We were able to quantify the effect lightweight construction – and specifically the use of structural optimization methods – has on the resources used in the SLM manufacturing process,” says Klaus Hoschke, scientist and group leader at Fraunhofer EMI. The focus was on energy and material consumption, the manufacturing time and the CO2 emissions that arise during the small-scale production of twelve wheel bearings.

After the researchers had used the numerical finite element method (FEM) to simulate and analyze a draft design and determine the right geometric shape with structural optimization methods, they constructed the wheel bearing in an optimized lightweight design. The result was a wheel bearing designed for the defined load scenarios and offering maximum performance. Because of their geometric complexity, structures produced in this way cannot be manufactured by conventional methods such as milling or turning. “With the lighter model, we were able to save hugely on resources during production, as less material has to be produced per component. If you multiply this by the number of units in a small-scale run, then you require less time, material and energy for manufacturing. Reducing volume through the use of higher-strength materials offers the greatest potential for energy savings here,” says the researcher. Using the numerically optimized version of the wheel bearing, 15 percent less energy was required for the additive process than for the conventional method: Twelve kilowatt hours of electricity were needed for the conventional design, whereas only ten kilowatt hours were needed for the numerically optimized design. (In each case, the measured value refers to a series-manufactured component.) Manufacturing time was cut by 14 percent and CO2 emissions by 19 percent. And where material consumption was concerned, it could be significantly reduced by 28 percent.

Although structure-optimizing algorithms and numerical optimization simulations are already being employed in the 3D printing of components today, they are only used when the component must be extremely lightweight, such as aircraft parts designed to reduce fuel consumption during operation. Components that lack these implications as regards structural optimization are still generally manufactured using conventional industrial methods. The results of the small-scale series production of the wheel bearing suggest that additive manufacturing can also be useful when a component does not have to be structurally optimized as such. “A heat exchanger or a tool mold, for example, do not have to be lightweight to improve their functionality. Nevertheless, it makes sense to design them with reduced weight and volume when manufacturing them additively, because this way you can bring down manufacturing costs,” explains Hoschke.

Forecasts on what effect the Additive Manufacturing of metals will have on global production vary widely. But everyone agrees on one thing: for many industries – such as aerospace, automotive engineering, medical engineering and toolmaking – it is a game changer. “Our positive results for resource efficiency in the manufacturing process should reinforce this,” says the scientist. In the future, Hoschke and his team want to research the extent to which other design heights, series sizes and materials such as titanium affect the resource efficiency of the manufacturing process.