Featured Client: A Distinctly Different Racquet: Composites Simulation Technology and Sporting Goods

Wimbledon 2016; what a ride! The shocking departure of 4 Slams winner Novak Djokovic, Roger Federer’s exciting quarter final win, Andy Murray’s victory over Milos Raonic, Serena Williams’ win of her 22nd Grand Slam title tying Steffi Graf’s record of major honors in the Open era and many more….my Facebook newsfeed stayed abuzz with exciting updates from this year’s Wimbledon; the oldest, one of the most prestigious tennis tournaments in the world. The only major tournament to be played on grass courts, held every year at the All England Club in Wimbledon, London since 1877 and one of four Grand Slam tennis tournaments along with the US Open, the Australian Open and the French Open, it attracts the world’s best tennis players as well as spectators from around the globe.

So what is so interesting about watching racquet sports? Well, interesting is certainly a mild description of the excitement reaching fever pitch and the heart pounding exhilaration that these matches can cause as we stay glued to our television sets watching them to the exclusion of everything else as life comes to a grinding halt. I believe, apart from entertaining us, relieving us of our stresses, bringing out the best (and worst) of our competitive spirits, it is the athletes themselves. The "wow" factor is watching the superior, high caliber tennis. Simply fascinating!

Our featured client this month is Wilson Sporting Goods, one of the world's leading manufacturers of high performance sports equipment, apparel and accessories. Creating, designing and producing sports equipment for more than a century for athletes who play Tennis, Golf, Baseball, Basketball, Football, Soccer, Volleyball, Softball and more, Wilson has helped continually evolve how sports are played and enjoyed by millions.

In the world of sports, the competition is fierce, and the relationship between an athlete and their equipment is a powerful one: it can be the defining difference and provide the winning advantage over an opponent. With that dynamic association in mind, Wilson Labs, the innovation hub at Wilson, invents, designs and engineers game-changing products, employing state-of-the-art sports technologies and expertise. In its Racquet Sports business, Wilson Lab’s innovation initiatives include material enhancements, mechanical enhancements, and changes to physical parameters of the racquet to fit evolving trends of the player’s game.

Exploring Composite Finite Element AnalysisWilson Labs engineers were interested in reducing design cycle time and enhancing product value by taking advantage of simulation, automation, and optimization technologies in the development of tennis racquets while accomplishing something unique or organic looking in terms of geometry. Until now, FEA for composites has been almost non-existent in the racquet industry. However, recognizing its benefit as a better tool for lay-up design as well as optimization for weight, strength, stiffness and simplicity, Wilson has taken on a leading role in employing this technology in the industry.

Modeling of Tennis Racquets in a Virtual EnvironmentWhile exploring developments in Finite Element Analysis Wilson (FEA) for methods that could be applied to their composite tennis racquet lines, Wilson Labs Innovation Manager of Racquet Sports, Bob Kapheim first became familiar with Altair’s HyperWorks® and Altair ProductDesign engineering services. While composites simulation technology was relatively new and advanced for the Wilson Labs racquet team and the sporting goods industry in general, Altair has worked extensively on composites simulation methods within industries such as aerospace that have been routinely employing the technology. With this mature offering and experience base, it was fairly simple for Altair to adapt the technology to the composites simulation of tennis racquets. “We knew Altair would be a good partner for us because they were able to demonstrate exactly how their software would work for an engineer – that was significant for us. And they worked with us to show how their product could tackle what we are looking to do. ” said Mr. Kapheim.

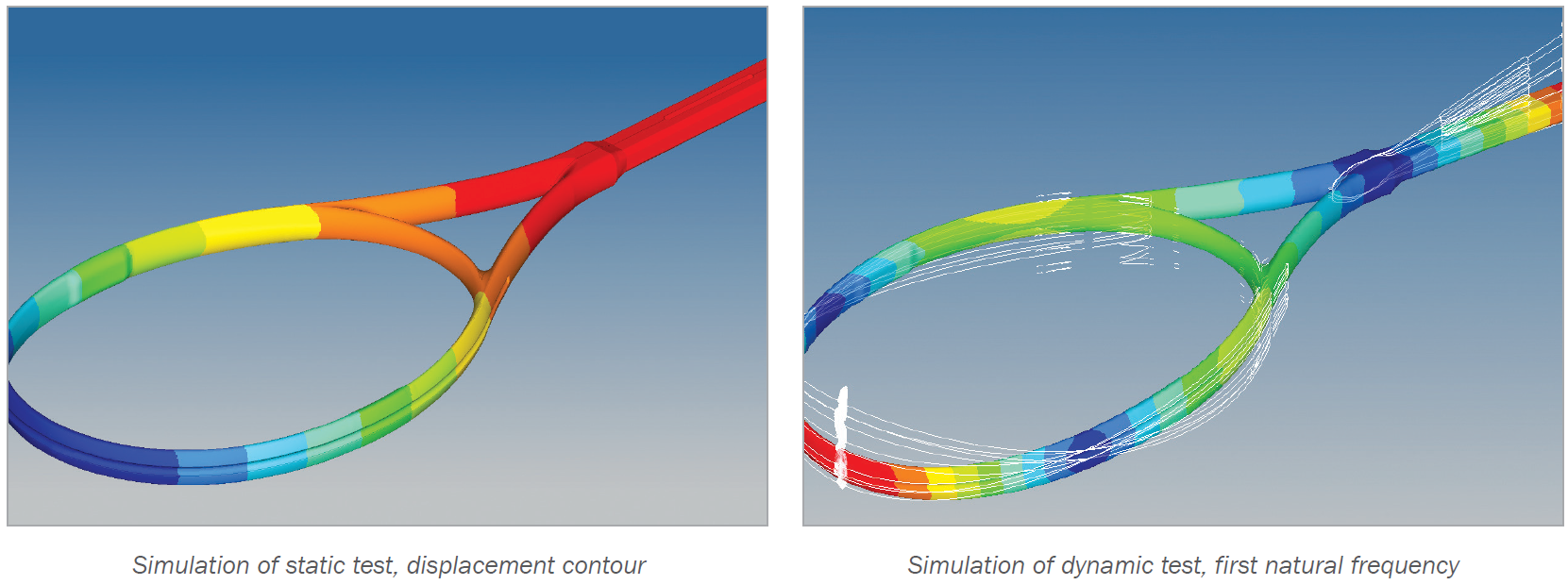

Altair’s engineers successfully modeled today’s tennis racquet in a virtual environment. Testing and analyses demonstrated the close correlation between a virtual model’s behaviors and real life behaviors.

The project inspired a high degree of confidence that HyperWorks brings the accuracy required to model the tennis racquets in a virtual space, and that virtual simulation as a resource is far more efficient than manual techniques.

The project inspired a high degree of confidence that HyperWorks brings the accuracy required to model the tennis racquets in a virtual space, and that virtual simulation as a resource is far more efficient than manual techniques.

Meeting the Metrics

For all the performance metrics expected by the Wilson Labs racquet team (mass, center of mass, dynamic stiffness, static stiffness) the results showed an error percentage of less than 4%. The mass showed an error within 3%, center of mass in 2%, frequency being the dynamic stiffness was in 1% error, and the static stiffness was in 4% error, demonstrating results that were far better than expected up front.

“I worked with Altair ProductDesign for roughly one year attempting to correlate a composite lay-up finite element model of a tennis racket, built in HyperWorks, to its real world counterpart. I was very impressed with Altair’s knowledge, hard work, quick response, and attention to detail. At the conclusion of the study, we were able to predict and verify within 4% error, at least four important performance characteristics of the tennis racket. We believe this will give us an advantage of speed to market in future product designs” concluded Mr. Kapheim.

For more details on this success story, please click here