Featured Client: SharkNinja Cleans Up in the Household Appliance Market

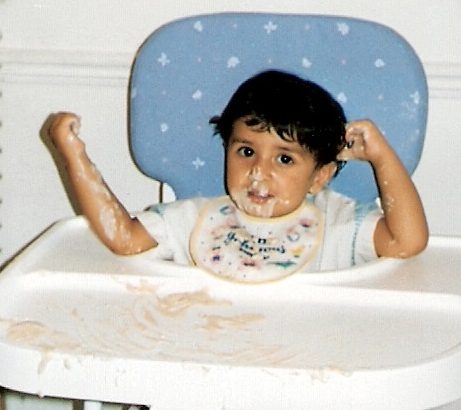

Satisfied gleam of victory as my (then) 2 year old gets mashed guava everywhere except his mouth. “I win (again) Mommy”

Satisfied gleam of victory as my (then) 2 year old gets mashed guava everywhere except his mouth. “I win (again) Mommy”After a life-time’s effort and all kinds of creative strategies to try to get him to eat fruits, my son, after all these years is still not a fruit fan. That is, until the gleaming display of a Ninja complete kitchen system caught my eye at Costco. In need of a good blender and food processor I went ahead and bought it (Yeah, Costco strikes again – you never can go in there and come out without spending more than you planned can you?)

The Ninja kitchen system came equipped with a Nutri Ninja (heavy duty juicer). Feeling like I had nothing to lose, I tried making a smoothie.

Oh what a dramatic overnight change in my household!

Not only did my son love it; for the first time since he’s been driving, he went to the supermarket to get all kinds of fruits so he could experiment with the Nutri Ninja! There’s been no turning back since then – a fruit/vegetable-rich smoothie a day makes for a happy mom and yes – a household with now other Shark Ninja appliances added!

Which brings me to our Featured Client of the Month. The following abridgement is based on an article by Beverly Beckert that was originally published in Concept to Reality Magazine’s Summer_Fall 2016 issue.

SharkNinja, formerly Euro-Pro LLC, made a name for itself through its Shark® and Ninja® products. In July 2015, Euro-Pro changed its company name to SharkNinja to establish one unified identity – and to capitalize on the awareness, consumer trust and success of each brand. Headquartered in Newton, MA, with offices across the US, UK, Canada and China, the company has been recognized as one of Inc. Magazine’s 5,000 fastest-growing companies in America. Through their unique offering of state-of-the art blenders and food processors, coffee bars, irons/steamers and vacuum cleaners, SharkNinja has strategically increased its share to 30% of the competitive U.S. household appliance market, with annual revenue reported at $1.6 billion dollars.

Other recent recognitions include being ranked the “Highest in Customer Satisfaction with Upright Vacuums” by the J.D. Power 2015 Vacuum Satisfaction Study(SM)

A Simulation Mindset

Based on a simulation-driven approach, SharkNinja uses a combination of analysis tools and techniques to gain a deeper understanding of product behavior, as well as improve product performance and durability with simulation tools from Altair’s HyperWorks® suite helping drive engineers’ efforts. It takes approximately 18 months for a product to go from concept to the store shelf, depending on the appliance.

In the case of vacuum cleaners, the process begins with marketing and industrial design (ID) teams pitching product requirements and functionality. Simulation is heavily involved throughout the process, as it helps product designers and analysts better understand the root cause of potential problems early in the design stage. In fact, it is the first step in a series of standard practices that Senior Mechanical Engineer Pu Zhou, the R&D and NPD (New Product Development Practices) lead has implemented at SharkNinja. “We use finite-element analysis (FEA) to simulate standard structures before tooling takes place so that we can identify any problems before they occur,” says Zhou. He adds that before every tool change, they run FEA to help ensure things go smoothly.

Time to market and cost drive internal measures of success. To help keep costs low, SharkNinja relies on global contractors with different skill levels to provide CAD models; however, the models are often in need of repair before analysis can take place. Simulation tools in the HyperWorks suite, such as SimLab®, help address this issue. SimLab automates simulation-modeling tasks to reduce human errors as well as cost and time spent manually creating finite-element models and interpreting results.

Time to market and cost drive internal measures of success. To help keep costs low, SharkNinja relies on global contractors with different skill levels to provide CAD models; however, the models are often in need of repair before analysis can take place. Simulation tools in the HyperWorks suite, such as SimLab®, help address this issue. SimLab automates simulation-modeling tasks to reduce human errors as well as cost and time spent manually creating finite-element models and interpreting results.

Zhou explains that the company wants its vacuum cleaners to be sturdy enough to withstand accidental drops or impact occurring during normal usage without mechanical failures or housing cracks. Using Altair’s HyperMesh®, a finite-element pre-processor for modeling complex geometries, and RADIOSS®, a nonlinear structural analysis solver, they do extensive drop testing, strength and durability analysis. AcuSolve® is used for Fluid dynamics simulation and flow analysis is performed to increase the suction power of vacuums and the mixing effectiveness of blenders.

Whether consumers prefer an upright or canister model, the lighter the vacuum, the better, especially when users have to carry the appliance up and down stairs. That’s why SharkNinja devotes time to light-weighting design initiatives such as in-house user testing, for which the company invites consumers to participate.

While analysis tools are used in product development, they also play a role in SharkNinja’s quality initiatives. The company’s Continuous Improvement team handles issues after mass production, often requesting engineering change modifications to products already on the shelf. Zhou collaborates with this team, running simulations before any new tooling takes place.

Structural analysis performed on vacuum cleaners nozzle, handle and body assemblies shows potential failure points during the product development phase

Structural analysis performed on vacuum cleaners nozzle, handle and body assemblies shows potential failure points during the product development phaseInnovative Decisions

SharkNinja’s innovative decision to adopt simulation technology in its NPD process – and make it a global standard practice – has strategically propelled the company to success. The R&D team can perform more virtual tests of different designs to see how they perform. Team members have been able to change the cost component of products by simulating performance with different materials. Manufacturing problems also have been averted or prevented through the use of simulation.

Zhou sums up, noting that the simulation tools – as well as support from Altair engineers – make a difference in global SharkNinja product development. “Simulation and Altair HyperWorks boost our capability to positively impact people’s lives every day in every home around the world”

To Read the full original story as it appeared in Concept to Reality Magazine click here.