Optimizing EV Traction Motor Performance from Concept Phase, Considering New Drive Cycles

Motor designers have to consider increasing conflicting constraints during the different design phases, like efficiency, temperature, weight, compactness or cost. Moreover, under strong environmental and governmental pressure during the past years, the automotive industry is continuously evolving to integrate new technology for their next generation vehicle powertrains.

Powertrain electrification and hybridization are the most common technologies considered to tackle undesirable fuel emissions linked to internal combustion engines (ICE). According to a recent J.P. Morgan research, old pure-ICE propulsion technology should decline to 70% of the worldwide market share in 2025, falling to around 40% by 2030. This represents a market of about 8.5 million electric vehicles (EV) and hybrid electric vehicles (HEV) in 2025; whereas in 2016 just under 1 million vehicles or 1% of global auto sales came from plug-in electric vehicles (PEVs). In the meantime, many capital cities declared they will ban polluting technologies, and most automakers announced a turn to electric propulsion with high conversion rates. A radical change is that this transformation will not only be led by premium manufacturers, but this decision concerns all the car manufacturers reorganizing their product range short term. With a few vehicle manufacturers having a head start of around 15 years, every new player needs to move quickly to produce their electric and hybrid vehicles. That means modern, efficient simulation solutions are needed to fill technological gaps.

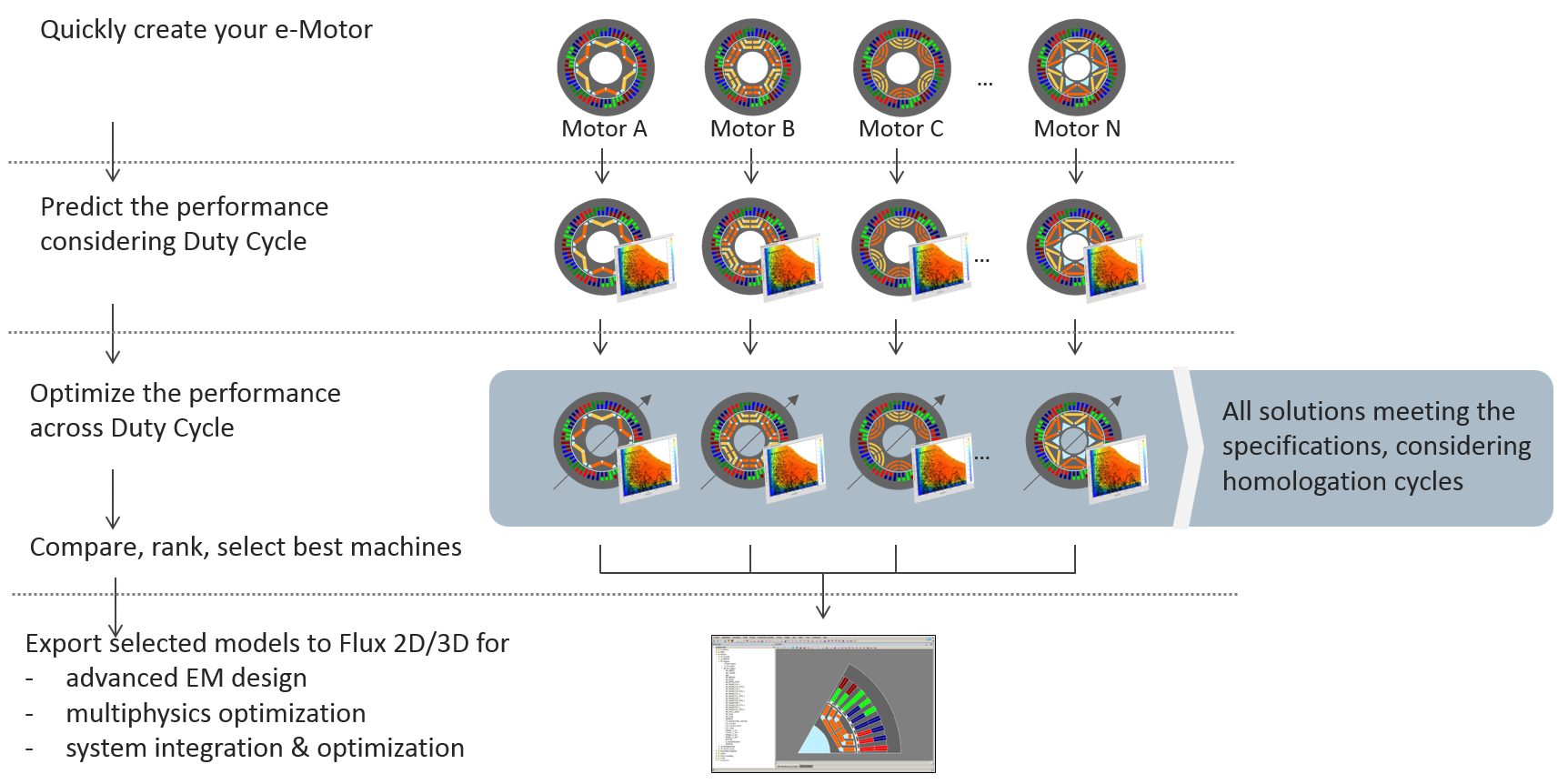

Convinced that Simulation-Driven Design is key for innovation, Altair proposes a disruptive process with its Multiphysics simulation and optimization platform Altair HyperWorksTM. The flexible and customizable environment guides motor designers through an efficient workflow to reduce design times, combining balanced design with accelerated time to market, in confidence. This article illustrates Altair unique process to design traction e-Motors by quickly comparing their performance during the concept phase and optimizing them considering driving cycles in order to select the most appropriate machine.

How to get the most from this new technology? How to attain the best efficiency, using best designs, configurations, materials, while offering the same level of comfort to passengers? Thanks to a dedicated motor platform, comprising efficient design exploration and optimization methods, thousands of variants can be efficiently analyzed and compared to find the best compromise in term of efficiency, performance, cost, noise, controllability, etc., before final multi-domain optimization.

Starting from an e-Motor Concept driven by Driving Cycle

Recent platforms dedicated to motor predesign, such as Altair FluxMotorTM, are addressing the motor designers with their “own” language. Far from CAD models, such platforms are considering classical motor parameters which characterize the machine, like as structural data: dimensions (inner / outer diameter, depth); number of poles and of magnets; topology (parts shapes, dimensions); winding architecture; coil composition (wire diameter, fill factor) or materials. Potentially, the number of configurations to consider is unlimited.

If for some applications, such as a constant speed belt conveyor, a machine with an ideal working point may be enough, whereas automotive applications are far more demanding. Designers should consider a large amount of working points related to a driving cycle to select best configuration. In this case, the typical Worldwide harmonized Light vehicles Test Procedure (WLTP) that represents the different acceleration, breaking, constant speed phases of a duty cycle is a major input.

Designing Concept Machines as a Starting Point

The start for the motor designer is the main specifications that can comprise max. current, max. voltage, min. power, torque to attain, max. speed, external dimensions but also temperature constraints.

If a manufacturer has previously developed a machine and is considering it as the development base to answer new, more demanding WLTP driving cycles, designers can only enter one machine type, evaluate its performance and optimize it across an driving an cycle, as describe below.

Based on experience, or existing equipment already integrated, motor designers start to explore new designs. In the FluxMotor dedicated environment, machines can quickly be assembled from existing parts from the supplied library, which can also be customized. “What if” combinations, for instance for winding architectural choice may be addressed quickly.

In order to efficiently make early strategic choices, such as topological ones, mathematical tools like Altair ComposeTM may be used to select the most appropriate machine depending on expected characteristics. For example, most car manufacturers choose to design permanent magnet machines in order to benefit from maximum flux density, some others are trying to stay away from magnets to limit problems related to sourcing rare earth magnets.

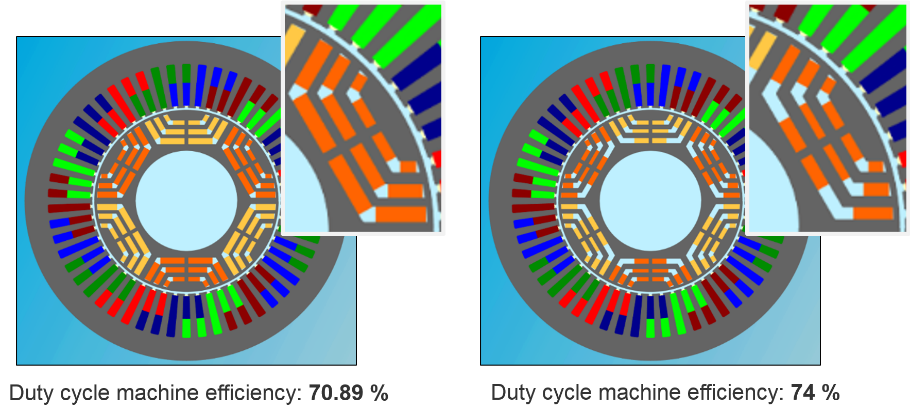

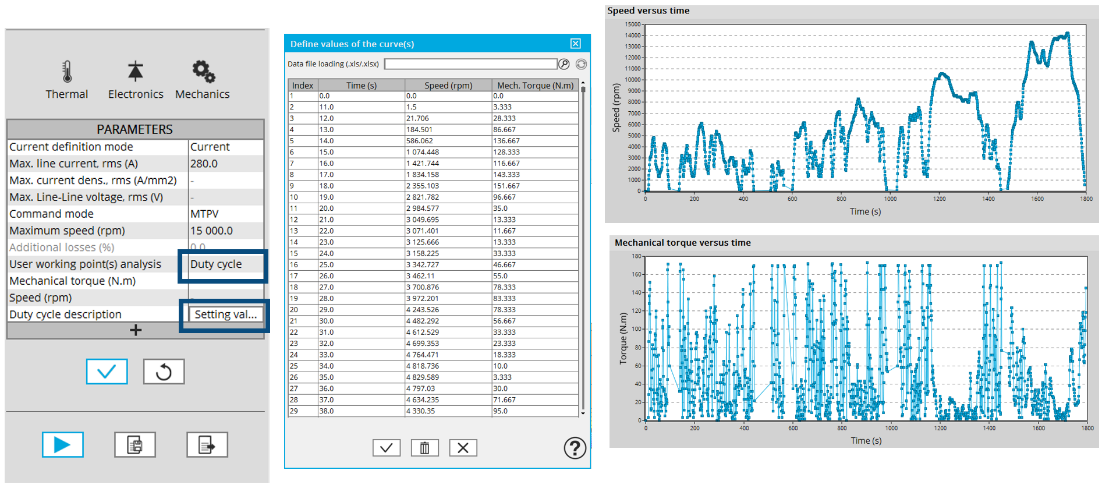

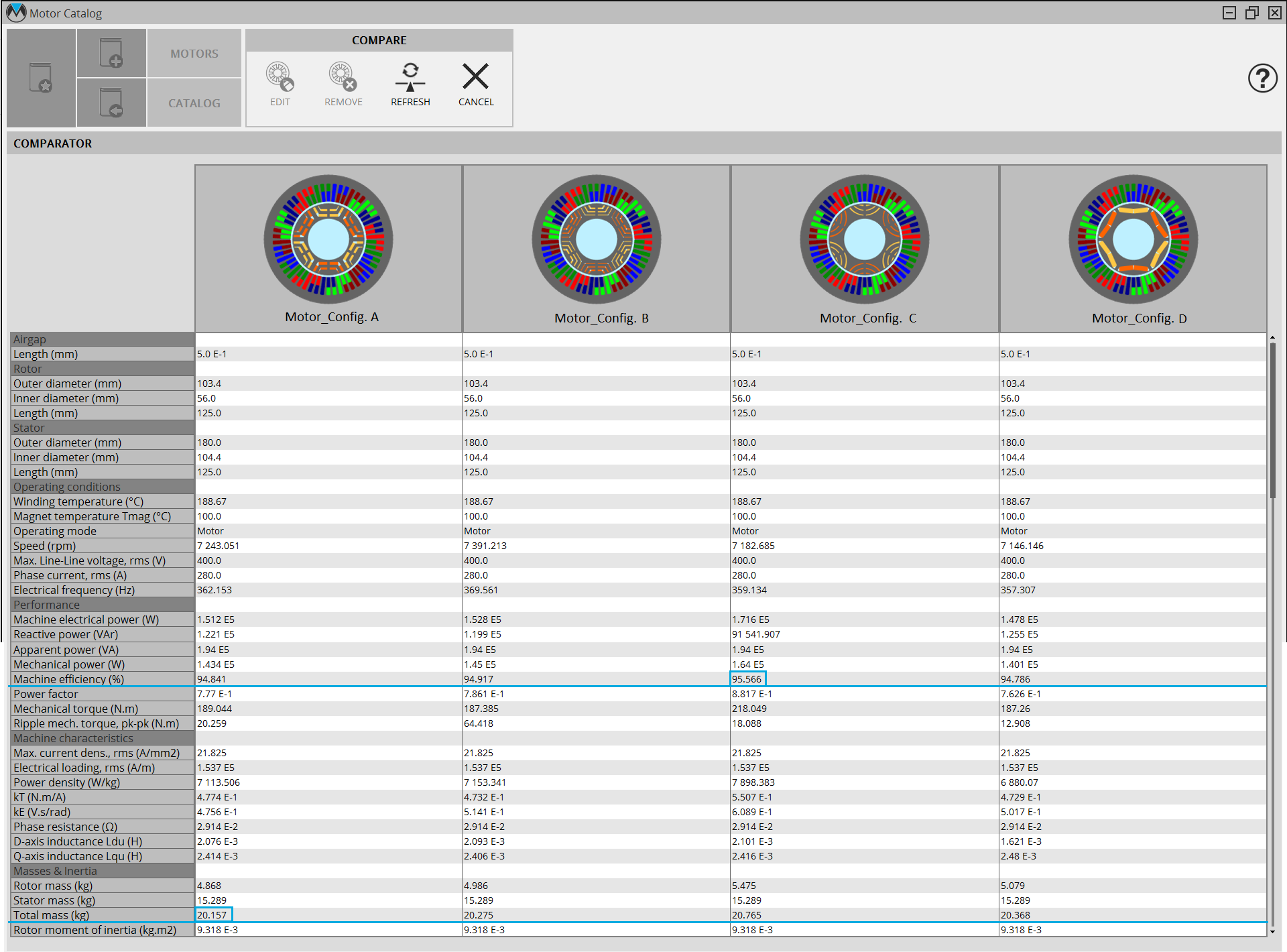

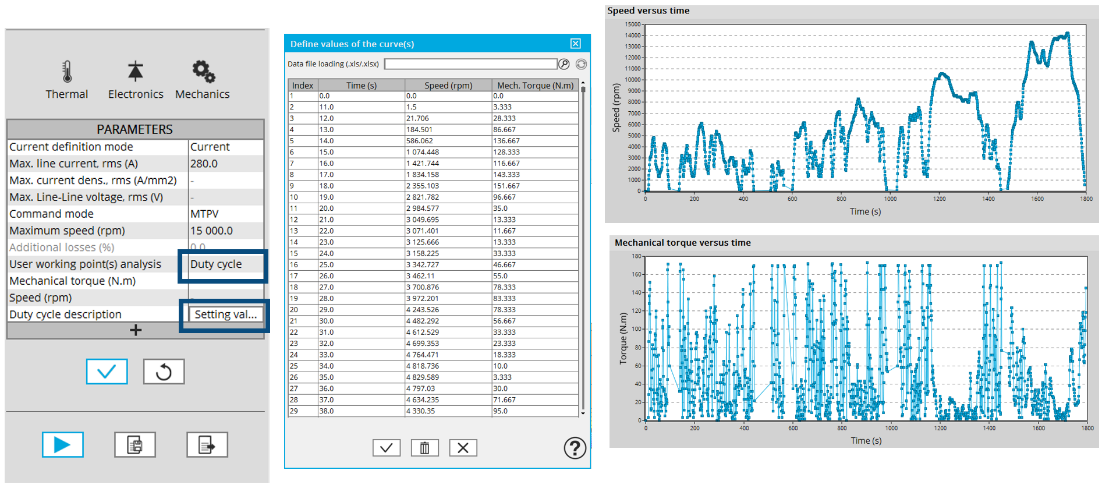

FluxMotor interface enables various working points, to be considered which can be entered as a text file

FluxMotor interface enables various working points, to be considered which can be entered as a text file

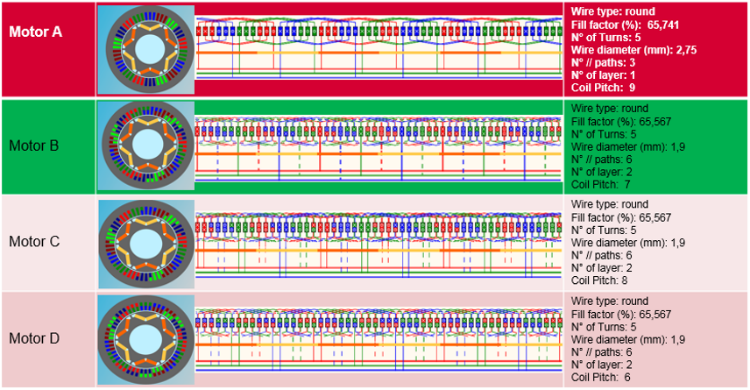

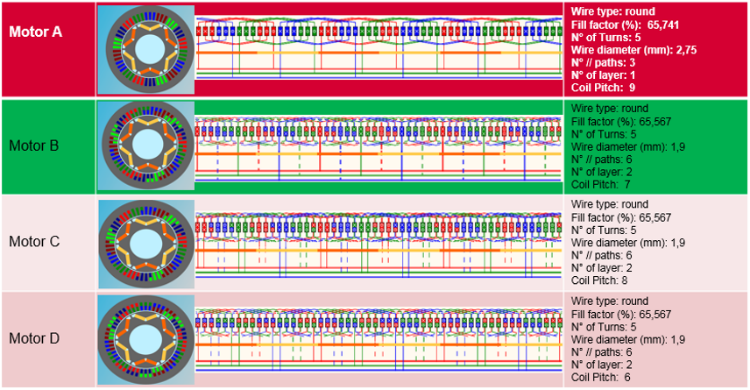

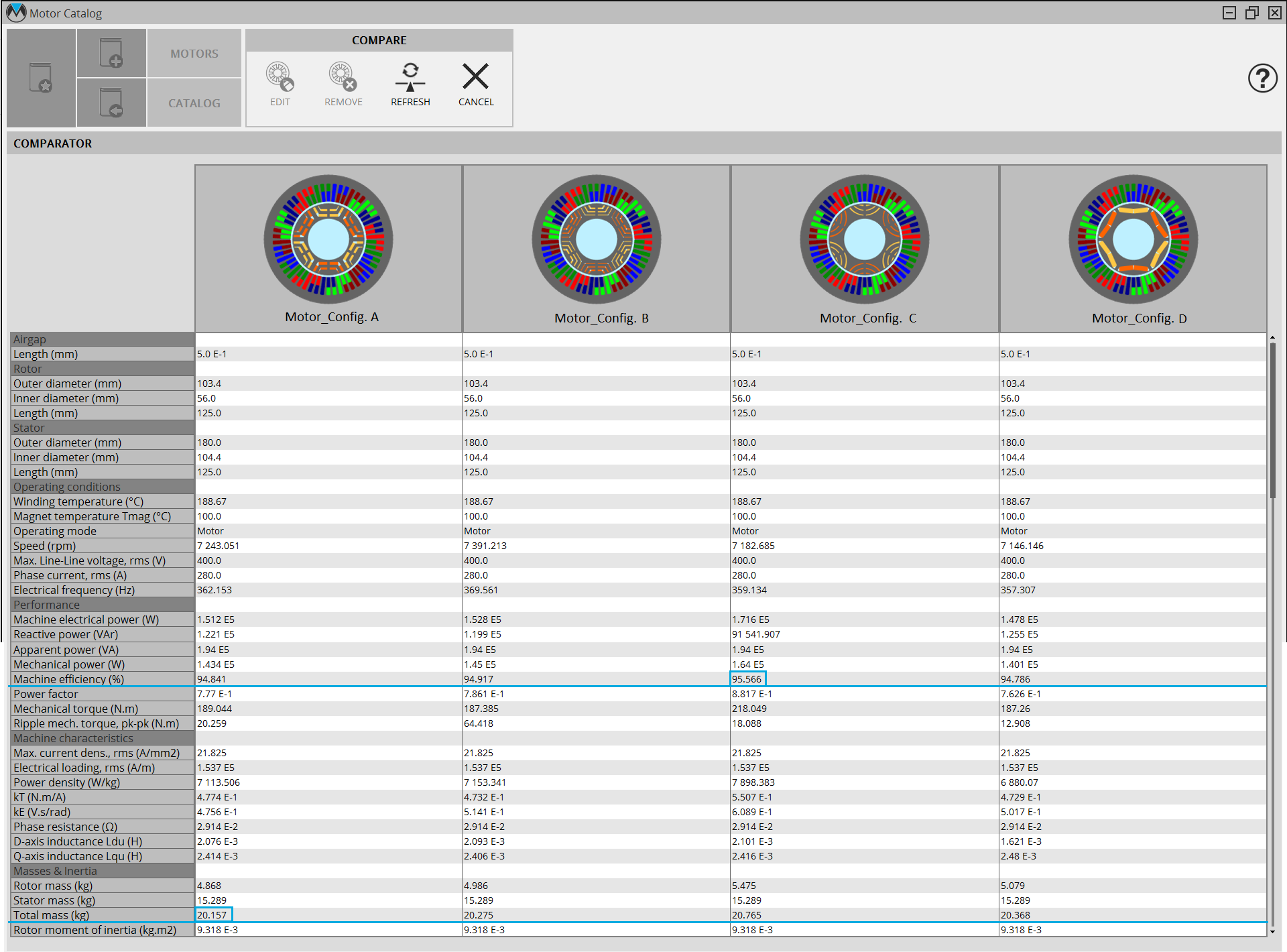

Evaluating the impact of different winding architecture on the machine performance across a duty cycle

Evaluating the impact of different winding architecture on the machine performance across a duty cycle

In most cases, different machine types will be selected. FluxMotor’s disruptive approach enables various working points to be considered, which may be entered as a text file. This efficient method, based on finite element model proved to be much more accurate than using analytical model, but doesn’t requires mcu time to produce results. In our application, WLTP driving cycles are described in a time / speed / torque point value list over the time.

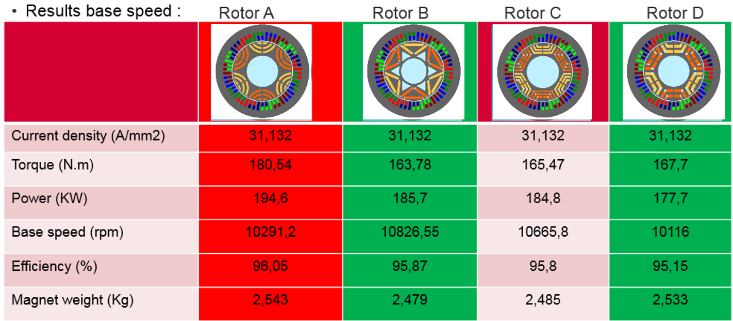

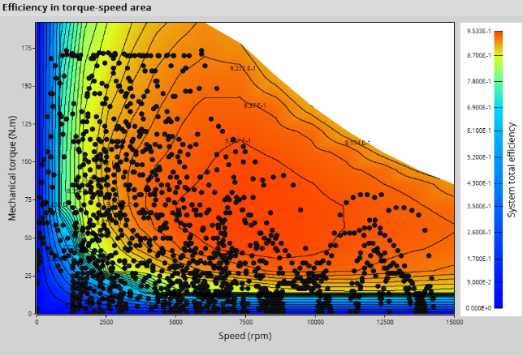

Among the various tests results, efficiency maps (torque / speed curves) are quickly computed, but efficiency analysis can also be performed in order to compute energy consumption across the driving cycle.

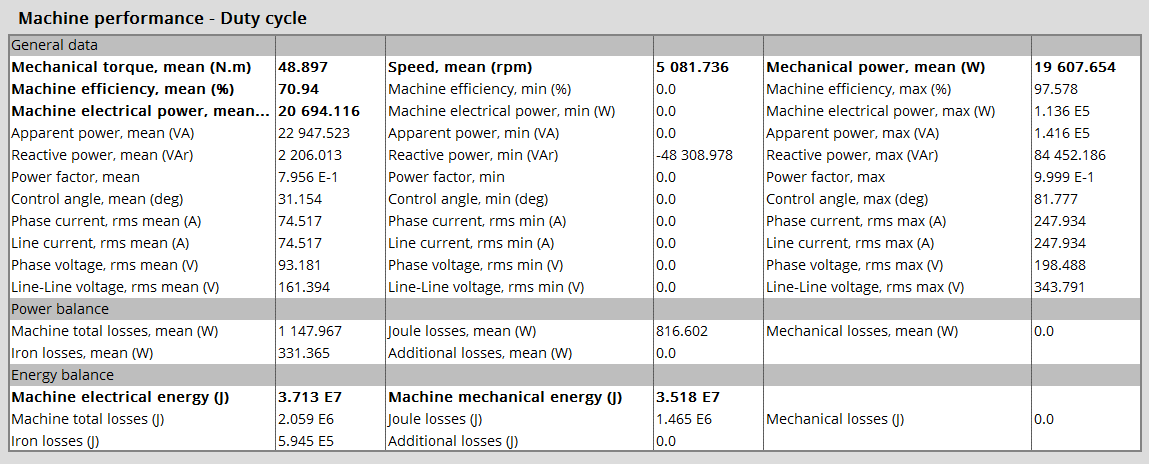

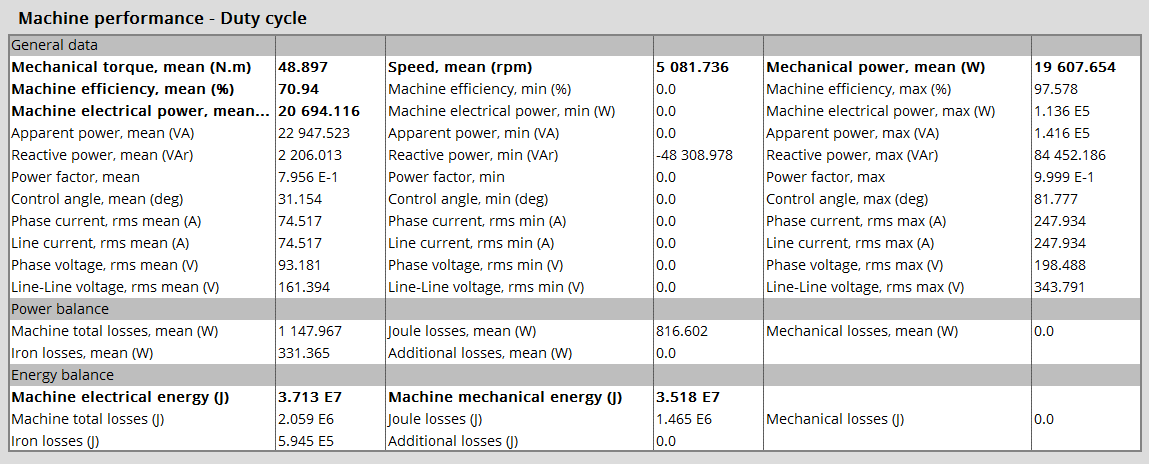

Comprehensive list of machine performance results computed in FluxMotor considering a full drive cycle

Comprehensive list of machine performance results computed in FluxMotor considering a full drive cycle

At this stage, results comparison enables designers to efficiently eliminate the worst-performing configurations. Depending on the level of performance expected, some or most of the motor configurations may not reach the target performance

Optimizing the Performance across WLTP

After evaluating the motor performance for a set of machines across a duty cycle, the next step is to optimize them but still considering driving cycles. For such considerations, Altair HyperStudyTM design exploration and optimization solutions can help to improve the design and save time leveraging in automatic processes and HPC.

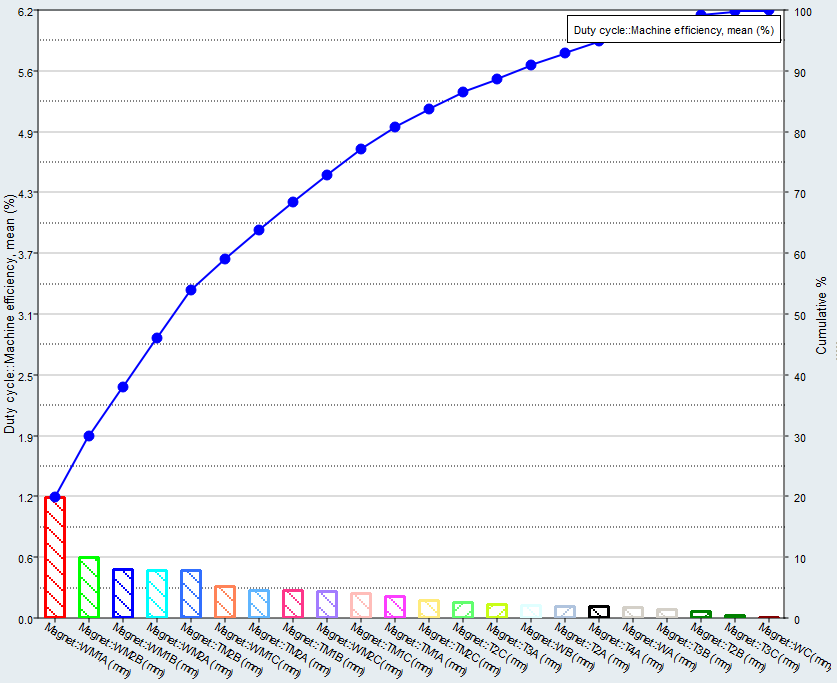

First, designers will likely launch a sensitivity analysis to investigate relationships between parameters and performance, identify the most relevant ones and screen out irrelevant ones.

Then, a set of automated computations will be launched.

Finally, HyperStudy will provide a series of optimized motors that fulfill the specified requirements, while offering the desire level of performance across the working cycle.

Back to FluxMotor, those machines can be further analyzed and compared.

A certain number of primary non-identified parameters, such as production cost linked to some exotic forms of laminations or magnets, help to make further choices to avoid certain types of configurations, or to refine optimization scenarios.

Next step: Optimizing the full Powertrain, considering WLTP Drive Cycles

Once this set of motors offering expected levels of performance across the driving cycle has been selected, the Altair Multiphysics platform enables further tests to be performed. Exporting the FluxMotor model to Altair FluxTM 2D/skew/3D enables advanced electromagnetics analyses, for instance to launch a short circuit test, study magnet demagnetization, compute Iron losses, perform eccentricity analysis, evaluate temperature impact on the parts, etc.

By coupling the Flux EM model to Altair OptiStructTM mechanical solver, noise emitted by e-Motors may be reduced, and stress computation will enable a more robust machine to be designed. Coupling the Altair AcuSolveTM CFD solver enables thermal analysis to be performed, in order to implement the most efficient cooling strategies.

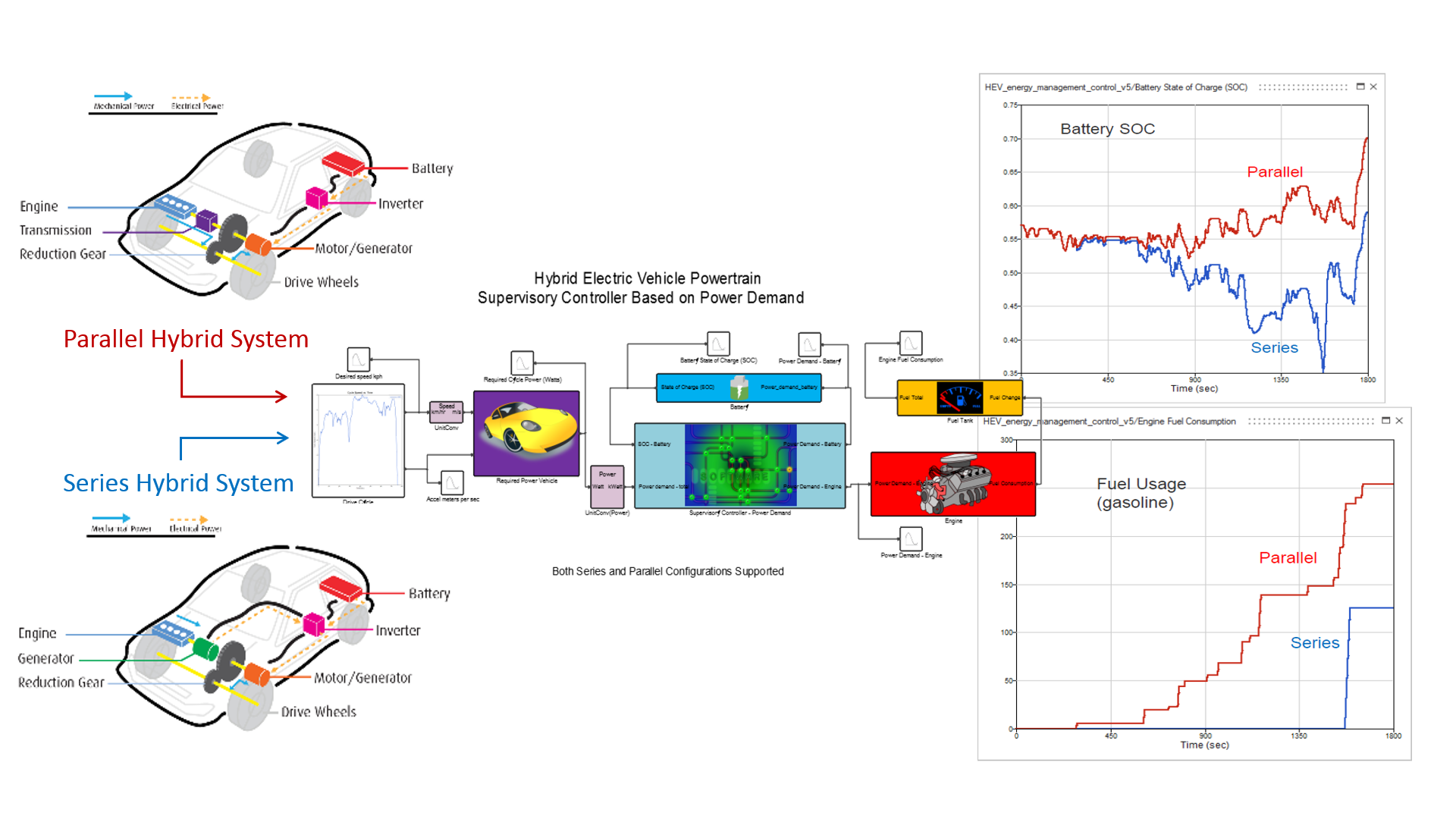

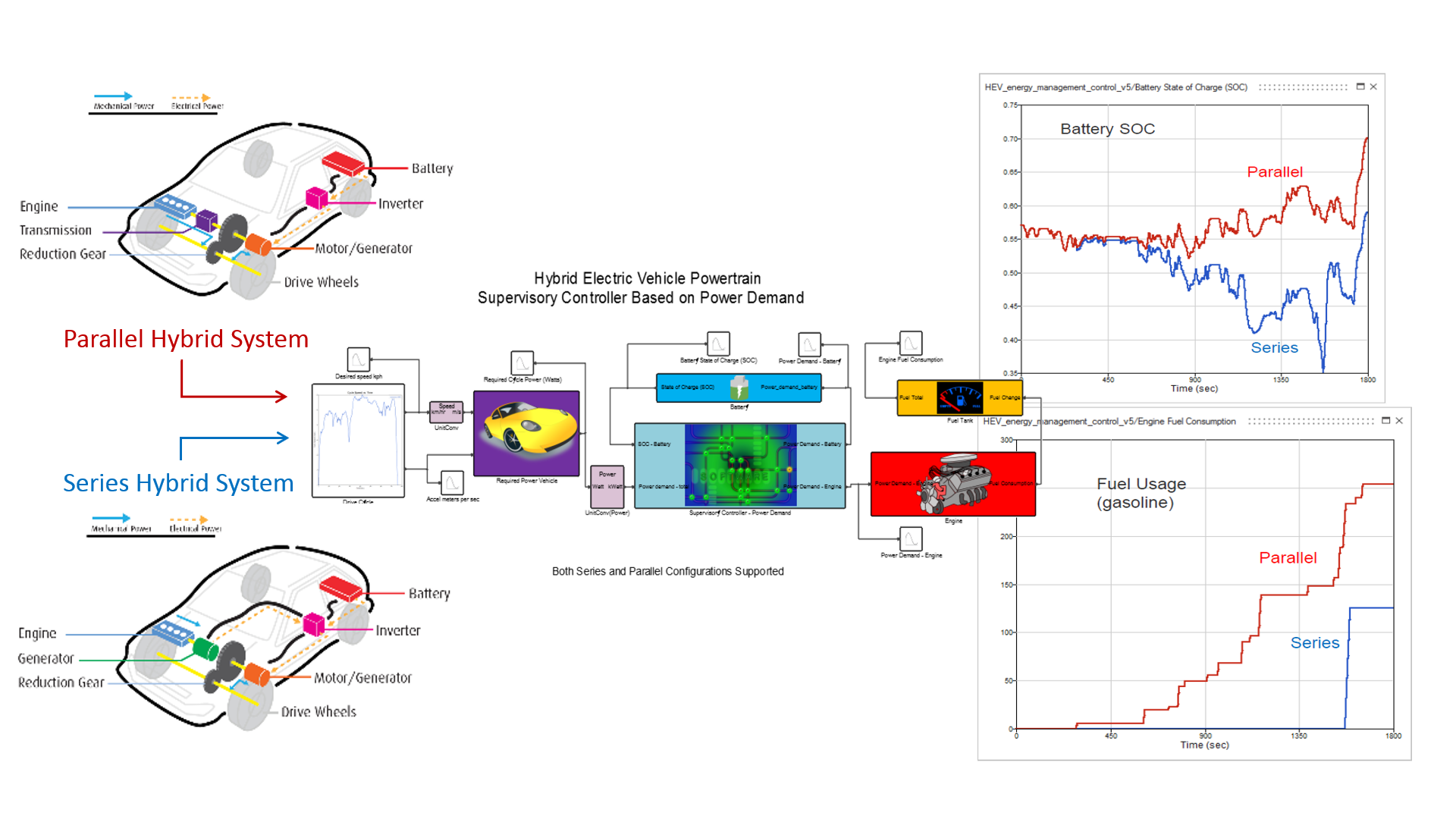

Altair SimLabTM pre-processing environment helps to parametrize and mesh complex CAD geometries according to different physical requirements, enabling multi-disciplinary optimization with Altair HyperStudyTM considering interactions. The most efficient motors can then be integrated in a global system modeling in Altair ActivateTM, comprising inverters, battery models, by taking into account drive and control strategies in order to consider and optimize the full powertrain performance across the drive cycle.

System simulation enables full powertrain integration and perform global optimization in order to make informed strategic decisions, like vehicle parallel / serial hybridization architectural choices

System simulation enables full powertrain integration and perform global optimization in order to make informed strategic decisions, like vehicle parallel / serial hybridization architectural choices

Learn more about Altair's detailed solution in our on-demand webinar presentation

Powertrain electrification and hybridization are the most common technologies considered to tackle undesirable fuel emissions linked to internal combustion engines (ICE). According to a recent J.P. Morgan research, old pure-ICE propulsion technology should decline to 70% of the worldwide market share in 2025, falling to around 40% by 2030. This represents a market of about 8.5 million electric vehicles (EV) and hybrid electric vehicles (HEV) in 2025; whereas in 2016 just under 1 million vehicles or 1% of global auto sales came from plug-in electric vehicles (PEVs). In the meantime, many capital cities declared they will ban polluting technologies, and most automakers announced a turn to electric propulsion with high conversion rates. A radical change is that this transformation will not only be led by premium manufacturers, but this decision concerns all the car manufacturers reorganizing their product range short term. With a few vehicle manufacturers having a head start of around 15 years, every new player needs to move quickly to produce their electric and hybrid vehicles. That means modern, efficient simulation solutions are needed to fill technological gaps.

Convinced that Simulation-Driven Design is key for innovation, Altair proposes a disruptive process with its Multiphysics simulation and optimization platform Altair HyperWorksTM. The flexible and customizable environment guides motor designers through an efficient workflow to reduce design times, combining balanced design with accelerated time to market, in confidence. This article illustrates Altair unique process to design traction e-Motors by quickly comparing their performance during the concept phase and optimizing them considering driving cycles in order to select the most appropriate machine.

How to get the most from this new technology? How to attain the best efficiency, using best designs, configurations, materials, while offering the same level of comfort to passengers? Thanks to a dedicated motor platform, comprising efficient design exploration and optimization methods, thousands of variants can be efficiently analyzed and compared to find the best compromise in term of efficiency, performance, cost, noise, controllability, etc., before final multi-domain optimization.

Starting from an e-Motor Concept driven by Driving Cycle

Recent platforms dedicated to motor predesign, such as Altair FluxMotorTM, are addressing the motor designers with their “own” language. Far from CAD models, such platforms are considering classical motor parameters which characterize the machine, like as structural data: dimensions (inner / outer diameter, depth); number of poles and of magnets; topology (parts shapes, dimensions); winding architecture; coil composition (wire diameter, fill factor) or materials. Potentially, the number of configurations to consider is unlimited.

If for some applications, such as a constant speed belt conveyor, a machine with an ideal working point may be enough, whereas automotive applications are far more demanding. Designers should consider a large amount of working points related to a driving cycle to select best configuration. In this case, the typical Worldwide harmonized Light vehicles Test Procedure (WLTP) that represents the different acceleration, breaking, constant speed phases of a duty cycle is a major input.

Designing Concept Machines as a Starting Point

The start for the motor designer is the main specifications that can comprise max. current, max. voltage, min. power, torque to attain, max. speed, external dimensions but also temperature constraints.

If a manufacturer has previously developed a machine and is considering it as the development base to answer new, more demanding WLTP driving cycles, designers can only enter one machine type, evaluate its performance and optimize it across an driving an cycle, as describe below.

Based on experience, or existing equipment already integrated, motor designers start to explore new designs. In the FluxMotor dedicated environment, machines can quickly be assembled from existing parts from the supplied library, which can also be customized. “What if” combinations, for instance for winding architectural choice may be addressed quickly.

In order to efficiently make early strategic choices, such as topological ones, mathematical tools like Altair ComposeTM may be used to select the most appropriate machine depending on expected characteristics. For example, most car manufacturers choose to design permanent magnet machines in order to benefit from maximum flux density, some others are trying to stay away from magnets to limit problems related to sourcing rare earth magnets.

FluxMotor interface enables various working points, to be considered which can be entered as a text file

FluxMotor interface enables various working points, to be considered which can be entered as a text file Evaluating the impact of different winding architecture on the machine performance across a duty cycle

Evaluating the impact of different winding architecture on the machine performance across a duty cycleIn most cases, different machine types will be selected. FluxMotor’s disruptive approach enables various working points to be considered, which may be entered as a text file. This efficient method, based on finite element model proved to be much more accurate than using analytical model, but doesn’t requires mcu time to produce results. In our application, WLTP driving cycles are described in a time / speed / torque point value list over the time.

Among the various tests results, efficiency maps (torque / speed curves) are quickly computed, but efficiency analysis can also be performed in order to compute energy consumption across the driving cycle.

Comprehensive list of machine performance results computed in FluxMotor considering a full drive cycle

Comprehensive list of machine performance results computed in FluxMotor considering a full drive cycle

At this stage, results comparison enables designers to efficiently eliminate the worst-performing configurations. Depending on the level of performance expected, some or most of the motor configurations may not reach the target performance

Optimizing the Performance across WLTP

After evaluating the motor performance for a set of machines across a duty cycle, the next step is to optimize them but still considering driving cycles. For such considerations, Altair HyperStudyTM design exploration and optimization solutions can help to improve the design and save time leveraging in automatic processes and HPC.

First, designers will likely launch a sensitivity analysis to investigate relationships between parameters and performance, identify the most relevant ones and screen out irrelevant ones.

Then, a set of automated computations will be launched.

Finally, HyperStudy will provide a series of optimized motors that fulfill the specified requirements, while offering the desire level of performance across the working cycle.

Back to FluxMotor, those machines can be further analyzed and compared.

A certain number of primary non-identified parameters, such as production cost linked to some exotic forms of laminations or magnets, help to make further choices to avoid certain types of configurations, or to refine optimization scenarios.

Next step: Optimizing the full Powertrain, considering WLTP Drive Cycles

Once this set of motors offering expected levels of performance across the driving cycle has been selected, the Altair Multiphysics platform enables further tests to be performed. Exporting the FluxMotor model to Altair FluxTM 2D/skew/3D enables advanced electromagnetics analyses, for instance to launch a short circuit test, study magnet demagnetization, compute Iron losses, perform eccentricity analysis, evaluate temperature impact on the parts, etc.

By coupling the Flux EM model to Altair OptiStructTM mechanical solver, noise emitted by e-Motors may be reduced, and stress computation will enable a more robust machine to be designed. Coupling the Altair AcuSolveTM CFD solver enables thermal analysis to be performed, in order to implement the most efficient cooling strategies.

Altair SimLabTM pre-processing environment helps to parametrize and mesh complex CAD geometries according to different physical requirements, enabling multi-disciplinary optimization with Altair HyperStudyTM considering interactions. The most efficient motors can then be integrated in a global system modeling in Altair ActivateTM, comprising inverters, battery models, by taking into account drive and control strategies in order to consider and optimize the full powertrain performance across the drive cycle.

System simulation enables full powertrain integration and perform global optimization in order to make informed strategic decisions, like vehicle parallel / serial hybridization architectural choices

System simulation enables full powertrain integration and perform global optimization in order to make informed strategic decisions, like vehicle parallel / serial hybridization architectural choicesLearn more about Altair's detailed solution in our on-demand webinar presentation