Simulation-Driven Design and Manufacturing

“Any customer can have a car painted any color that he wants so long as it is black."

- Henry Ford (July 30, 1863 – April 7, 1947)

Today, when I see a white car on the road, I can hardly tell what the exact color is - oxford white, silver white, or ivory white. Similarly, neither can I make up my mind on which toothpaste to buy from the 100 varieties on the shelf. We have so many options nowadays and many of them are similar in nature.

Photo Credit: https://www.digitaltrends.com/cars/automotive-revolutions-100-years-apart-how-the-past-predicts-the-future-of-driving/

Photo Credit: https://www.digitaltrends.com/cars/automotive-revolutions-100-years-apart-how-the-past-predicts-the-future-of-driving/

Manufacturing today is not central, the supply chains are spread out across the globe along with their own silos of expertise. The concept of an extended enterprise with expert centers focusing on various areas of design and production have functionally fragmented the design engineering process into narrow areas of focus with overall performance and cost requirements being dictated by large OEMs to their tiered suppliers. As a result, designers and manufacturers are usually trying to do their best each.

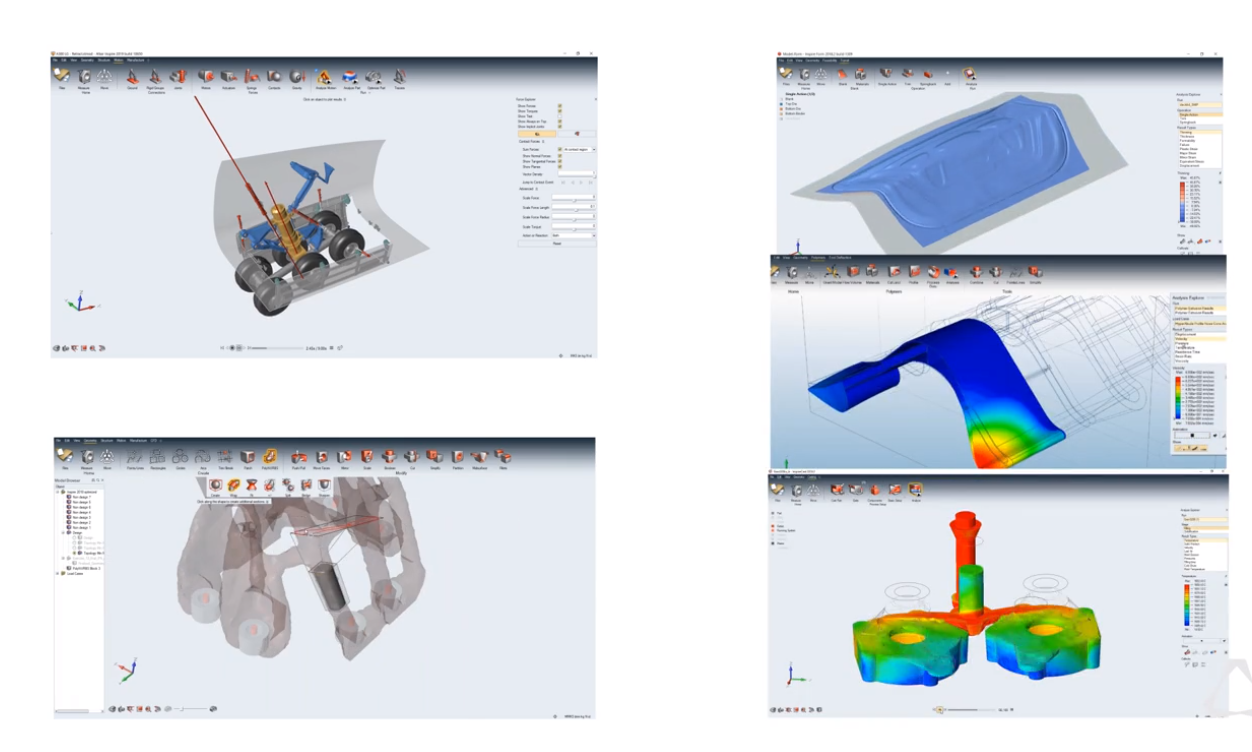

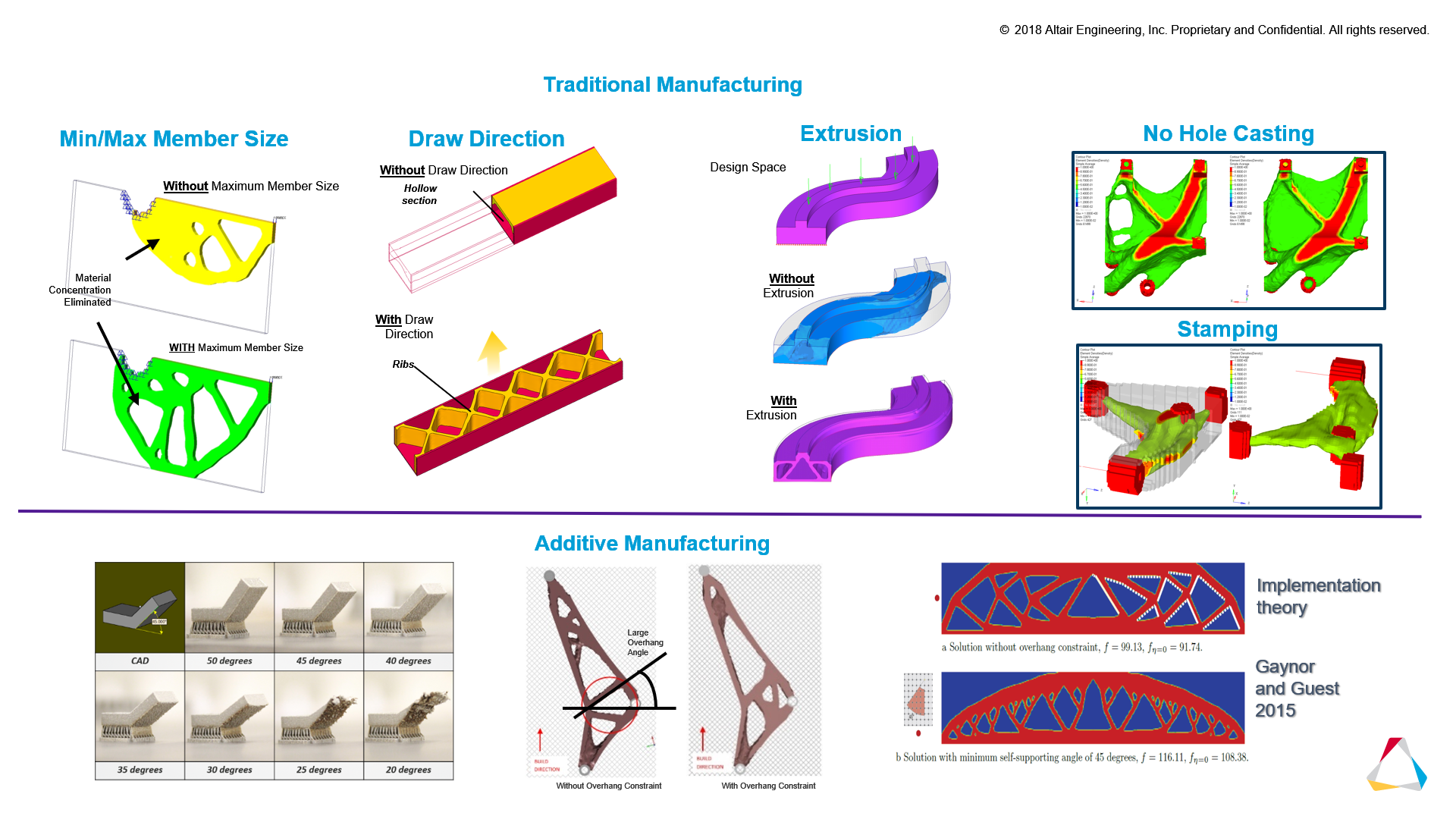

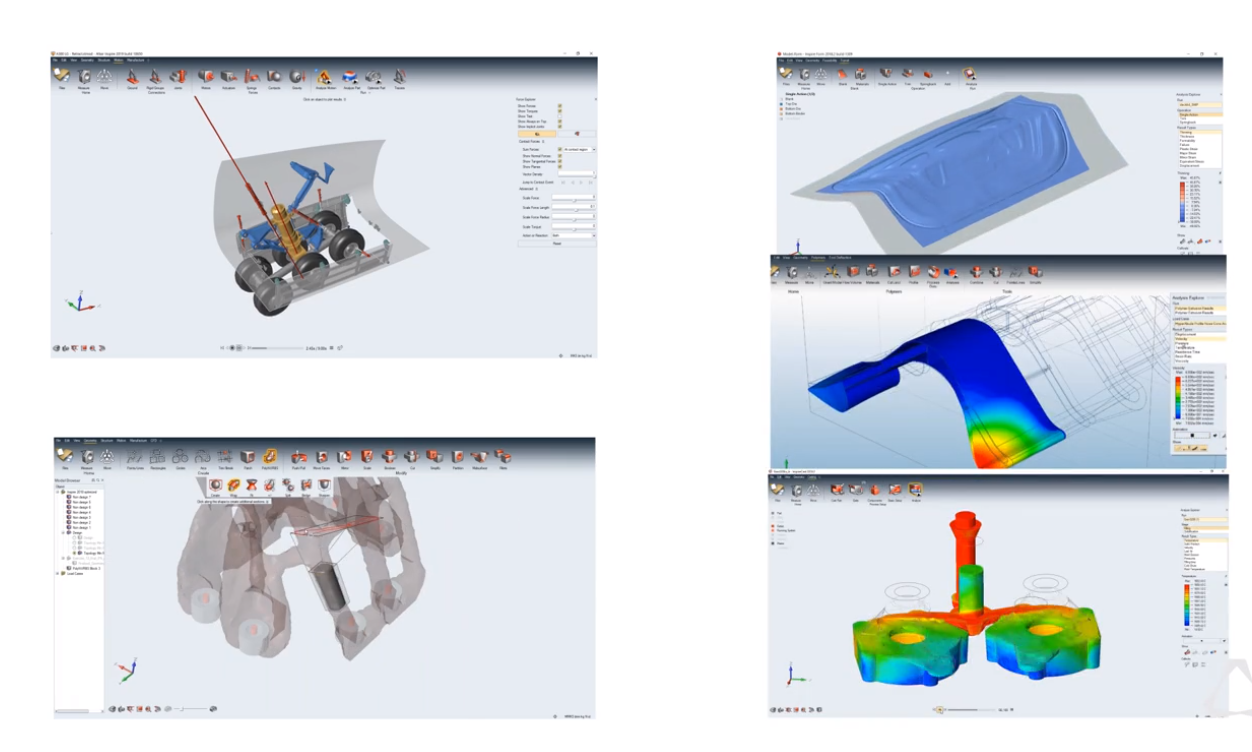

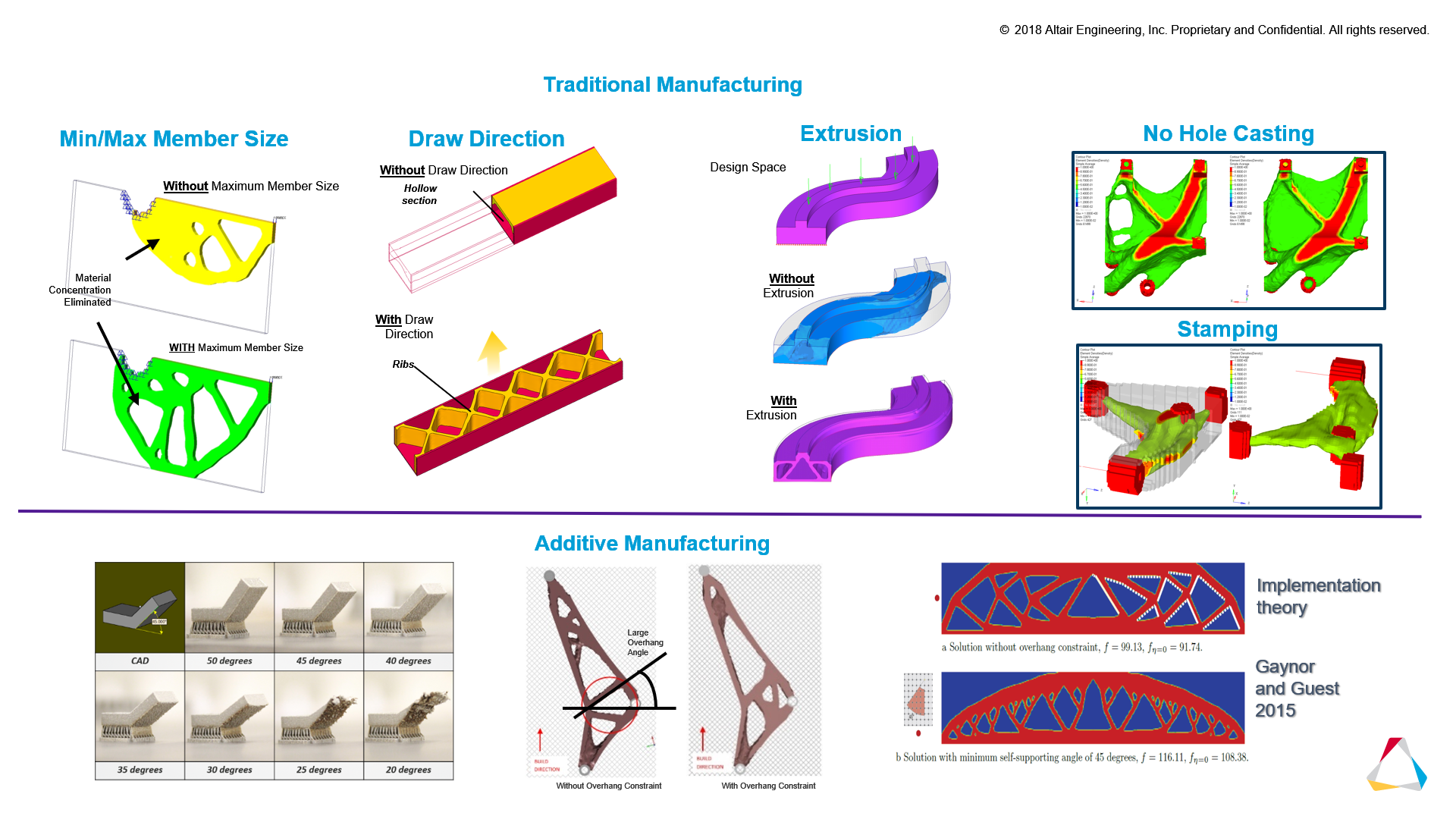

With the introduction of Altair OptiStruct, Altair pioneered the concept of simulation-driven design in the market suggesting organic and generative concepts based on sound numerical optimization techniques. The aerospace engineers could not get enough of the idea and enforced their supply chain to follow their process to reduce weight. Soon automotive and other segments weighed in and started seeing the benefits. There were frequent requests to add constraints (rules) to the generative process so that the designs could be cognizant of the downstream production process leading to designs that meet the both performance and are also manufacturable.

were in the hands of CAE experts, who typically dealt with virtual validation of existing designs for performance improvement. They needed to be brought into the hands of the designers early in the design process. The design had to be driven while doing two things; one, to use the right manufacturing rules (constraints) to generate the designs; and two, to evaluate the manufacturing feasibility.

Working on both ends of the supply chain, with design optimization on one end and manufacturing process simulation tools on the other, both these capabilities were brought into a brand new Inspire platform to address early concept design and manufacturing. The combination of both of these technologies exists in Altair Inspire, an intuitive platform aimed at designers.

For the first time, at the Global Altair Technology Conference (ATC), we will be featuring workshops covering Design for Manufacturing for traditional and additive manufacturing in two different sessions. While additive manufacturing is a fascinating new way of making complex parts, with tremendous interest focus by many around the world to learn more, we also cannot neglect traditional manufacturing process and hybrid methods that combine both. One of the workshop tracks focuses solely on additive, while the other track focuses on traditional manufacturing.

ATC 2018 Workshop: “Simulation-Driven Design & Manufacturing / Showcase on High Pressure Die Casting”

The goals of this track are twofold: to introduce attendees to the Altair Inspire Platform for simulation-driven innovation with the purpose of introducing designers to drive their designs and to showcase how they can all be combined for high pressure die casting as an example. The idea is to familiarize the attendees on all considerations before making a design that is manufacturable.

In the introductory session, Martin Solina will cover the platform with Dr. Subir Roy and Ulrich Bruder followed by a presentation by Scania using a real-world example. Rainer Booke, an expert in the field of casting, will then take attendees through various aspects of the casting process, from quoting, to workflow, and quality improvements.

In the first session designers will learn:

Rainer’s session will cover the challenges and opportunities for the casting community, as well as quoting and anticipating defects and methods on how to address them using simulations.

I urge you to attend this workshop to get a good view on all the tools available for designers and manufacturing engineers and understand how to design products that are innovative and yet manufacturable.

Workshop: New Developments in Technology and Process for Design for Additive Manufacturing

This session is completely focused on 3D printing, with a variety of presentations from various industries, including a pioneering cost-effective serial printing showcased by BMW that won the 2018 Altair Enlighten award earlier this year.

You will also get a variety of 3D printing methods including hybrid methods in conjunction with Casting from Sogeclair and plastic injection molds being printed by Protiq. APA partner Amphyon, along with EOS, will present on how to optimize parts and the process to 3D print parts right the first time.

Marta García-Cosío from CITD will present on optimizing the design of Arianne Launcher’s umbilical brackets under complex loading and stringent milling manufacturing constraints that lead to part consolidation and cost reduction and a path for mass production. Renishaw will present design for additive manufacturing and all the considerations for high-quality production.

With so many great workshop options at ATC 2018, it may be challenging to pick just one! But let me assure you that any of the workshops you decide to attend will help you understand significantly more about manufacturing processes and how they influence designs. You will walk away with knowledge that will help you create highly innovative products.

To learn more about ATC 2018 and explore the workshop list, visit www.altairatc.com/https://altairatc.com/paris2018/

- Henry Ford (July 30, 1863 – April 7, 1947)

Today, when I see a white car on the road, I can hardly tell what the exact color is - oxford white, silver white, or ivory white. Similarly, neither can I make up my mind on which toothpaste to buy from the 100 varieties on the shelf. We have so many options nowadays and many of them are similar in nature.

Photo Credit: https://www.digitaltrends.com/cars/automotive-revolutions-100-years-apart-how-the-past-predicts-the-future-of-driving/

Photo Credit: https://www.digitaltrends.com/cars/automotive-revolutions-100-years-apart-how-the-past-predicts-the-future-of-driving/Manufacturing today is not central, the supply chains are spread out across the globe along with their own silos of expertise. The concept of an extended enterprise with expert centers focusing on various areas of design and production have functionally fragmented the design engineering process into narrow areas of focus with overall performance and cost requirements being dictated by large OEMs to their tiered suppliers. As a result, designers and manufacturers are usually trying to do their best each.

With the introduction of Altair OptiStruct, Altair pioneered the concept of simulation-driven design in the market suggesting organic and generative concepts based on sound numerical optimization techniques. The aerospace engineers could not get enough of the idea and enforced their supply chain to follow their process to reduce weight. Soon automotive and other segments weighed in and started seeing the benefits. There were frequent requests to add constraints (rules) to the generative process so that the designs could be cognizant of the downstream production process leading to designs that meet the both performance and are also manufacturable.

were in the hands of CAE experts, who typically dealt with virtual validation of existing designs for performance improvement. They needed to be brought into the hands of the designers early in the design process. The design had to be driven while doing two things; one, to use the right manufacturing rules (constraints) to generate the designs; and two, to evaluate the manufacturing feasibility.

Working on both ends of the supply chain, with design optimization on one end and manufacturing process simulation tools on the other, both these capabilities were brought into a brand new Inspire platform to address early concept design and manufacturing. The combination of both of these technologies exists in Altair Inspire, an intuitive platform aimed at designers.

For the first time, at the Global Altair Technology Conference (ATC), we will be featuring workshops covering Design for Manufacturing for traditional and additive manufacturing in two different sessions. While additive manufacturing is a fascinating new way of making complex parts, with tremendous interest focus by many around the world to learn more, we also cannot neglect traditional manufacturing process and hybrid methods that combine both. One of the workshop tracks focuses solely on additive, while the other track focuses on traditional manufacturing.

ATC 2018 Workshop: “Simulation-Driven Design & Manufacturing / Showcase on High Pressure Die Casting”

The goals of this track are twofold: to introduce attendees to the Altair Inspire Platform for simulation-driven innovation with the purpose of introducing designers to drive their designs and to showcase how they can all be combined for high pressure die casting as an example. The idea is to familiarize the attendees on all considerations before making a design that is manufacturable.

In the introductory session, Martin Solina will cover the platform with Dr. Subir Roy and Ulrich Bruder followed by a presentation by Scania using a real-world example. Rainer Booke, an expert in the field of casting, will then take attendees through various aspects of the casting process, from quoting, to workflow, and quality improvements.

In the first session designers will learn:

- using advanced manufacturing constraints

- understanding manufacturing defects on what can go wrong downstream in casting, sheet metal forming, metal and polymer extrusion and injection molding and also 3D printing

- how a user can put the above together to generate designs that are manufacturable

- how to collaborate within an enterprise and with the extended supply chain through the Altair 365 platform

Rainer’s session will cover the challenges and opportunities for the casting community, as well as quoting and anticipating defects and methods on how to address them using simulations.

I urge you to attend this workshop to get a good view on all the tools available for designers and manufacturing engineers and understand how to design products that are innovative and yet manufacturable.

Workshop: New Developments in Technology and Process for Design for Additive Manufacturing

This session is completely focused on 3D printing, with a variety of presentations from various industries, including a pioneering cost-effective serial printing showcased by BMW that won the 2018 Altair Enlighten award earlier this year.

You will also get a variety of 3D printing methods including hybrid methods in conjunction with Casting from Sogeclair and plastic injection molds being printed by Protiq. APA partner Amphyon, along with EOS, will present on how to optimize parts and the process to 3D print parts right the first time.

Marta García-Cosío from CITD will present on optimizing the design of Arianne Launcher’s umbilical brackets under complex loading and stringent milling manufacturing constraints that lead to part consolidation and cost reduction and a path for mass production. Renishaw will present design for additive manufacturing and all the considerations for high-quality production.

With so many great workshop options at ATC 2018, it may be challenging to pick just one! But let me assure you that any of the workshops you decide to attend will help you understand significantly more about manufacturing processes and how they influence designs. You will walk away with knowledge that will help you create highly innovative products.

To learn more about ATC 2018 and explore the workshop list, visit www.altairatc.com/https://altairatc.com/paris2018/