Top 5 things You Need to Know About the Altair Inspire™ Platform

The new, disruptive licensing model for the solidThinking suite and Altair Inspire™ as a platform is launched! Stop designing like it’s 1999, the future of simulation-driven design is here. Read, watch and take action!

Where Innovation Begins

Altair Inspire is a software platform that enable designers and design engineers to generate the most efficient concepts with focus on performance and manufacturability. This leads to reduced costs, shortened product development time, minimal material consumption and lightweight design.

Simulation-driven Design

We all designed parts the old way, in silos or throwing designs over the wall to get analyzed. And after many iterations finalize a design. Meanwhile much of a time, money and productivity is lost. Wait…we haven’t started discussion on manufacturing methods, and how design will affect tooling, machining, 3D printing or other manufacturing options for this design.

Applying a simulation-driven design approach, the Altair Inspire platform answers these exact problems in the design process. Early simulations in the product development process such as Finite Element (FE) analysis, kinematic and dynamic motions, design optimization, and manufacturing processes drive how design should be while satisfying all structural design criteria.

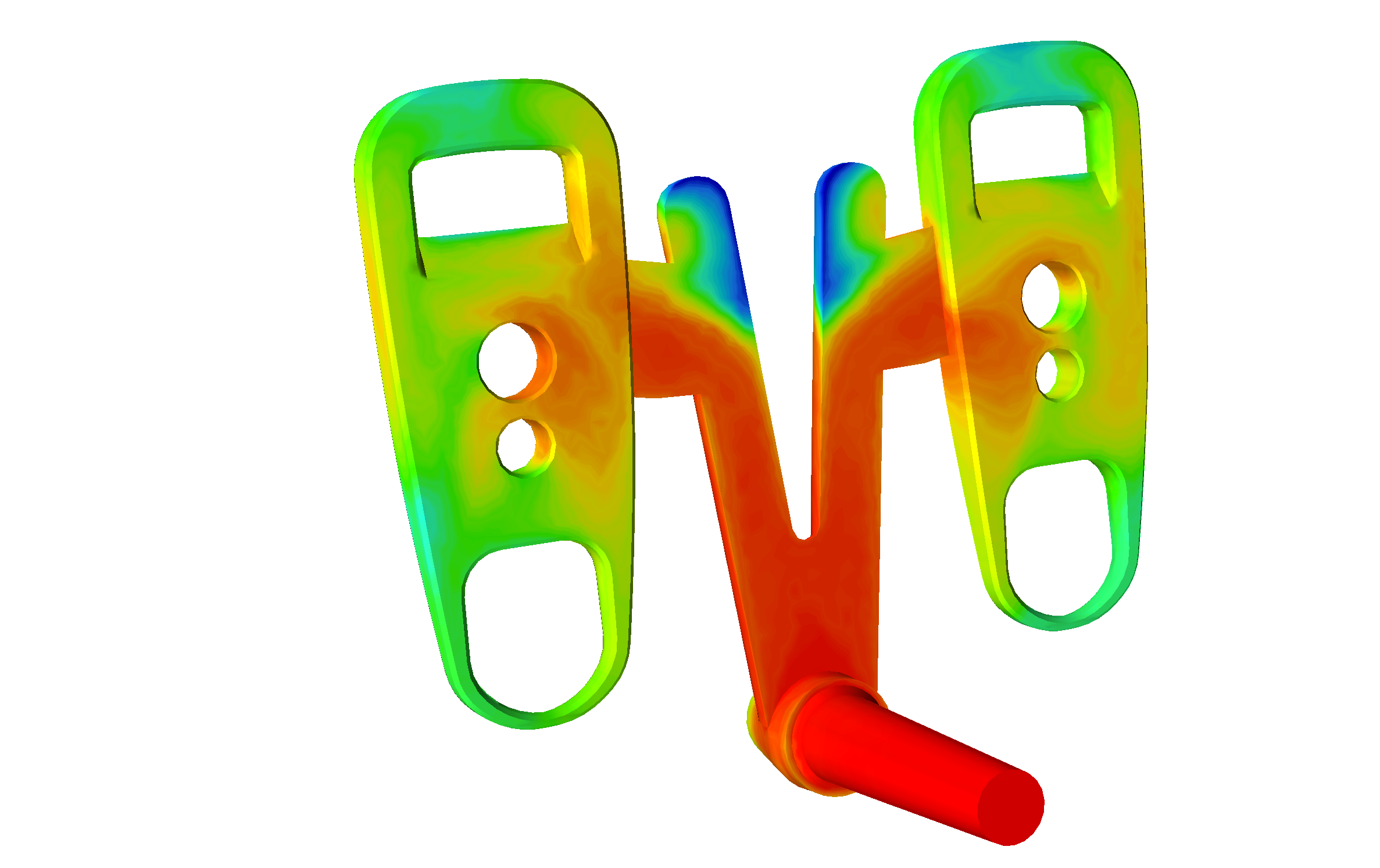

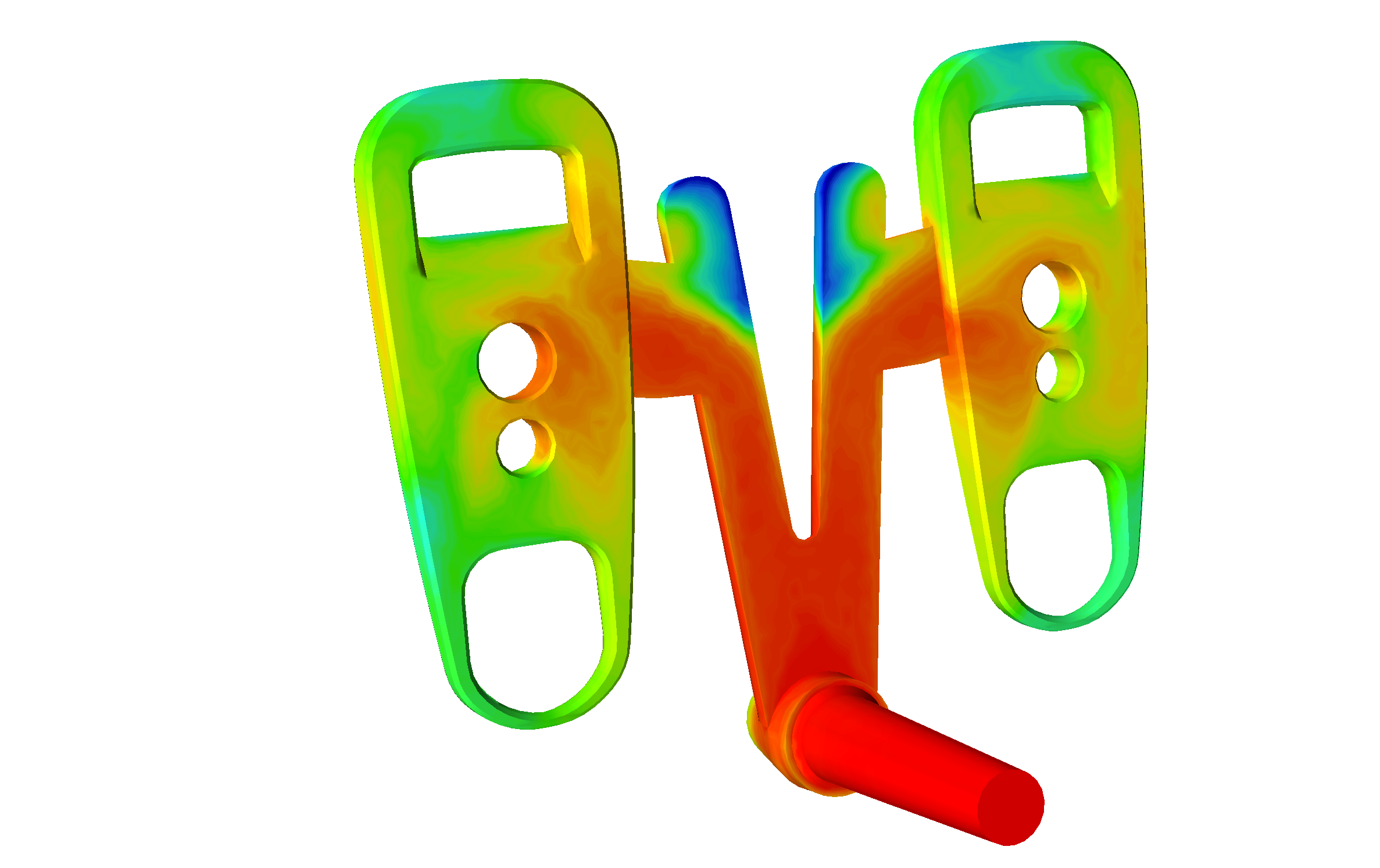

Additive and traditional manufacturing processes, like the casting simulation shown here, are supported

Additive and traditional manufacturing processes, like the casting simulation shown here, are supported

Manufacturability

Altair Inspire allows users to assign manufacturing constrains for both traditional and additive manufacturing processes. One can select method to create a design for casting, or machining or create a design to take advantage of the additive process. It’s easy to control overhang angles to reduce or eliminate support structure requirement during 3D printing. It also helps users to find out best orientation for the part given 3D printer specifications. Design comparison features helps engineers make intelligent design decisions using qualitative and quantitative data.

Then engineers can quickly run manufacturing feasibility simulation on newly generated design concept. Also run detailed casting, forming, or extrusion simulations to determine if a design fits for the specific manufacturing process.

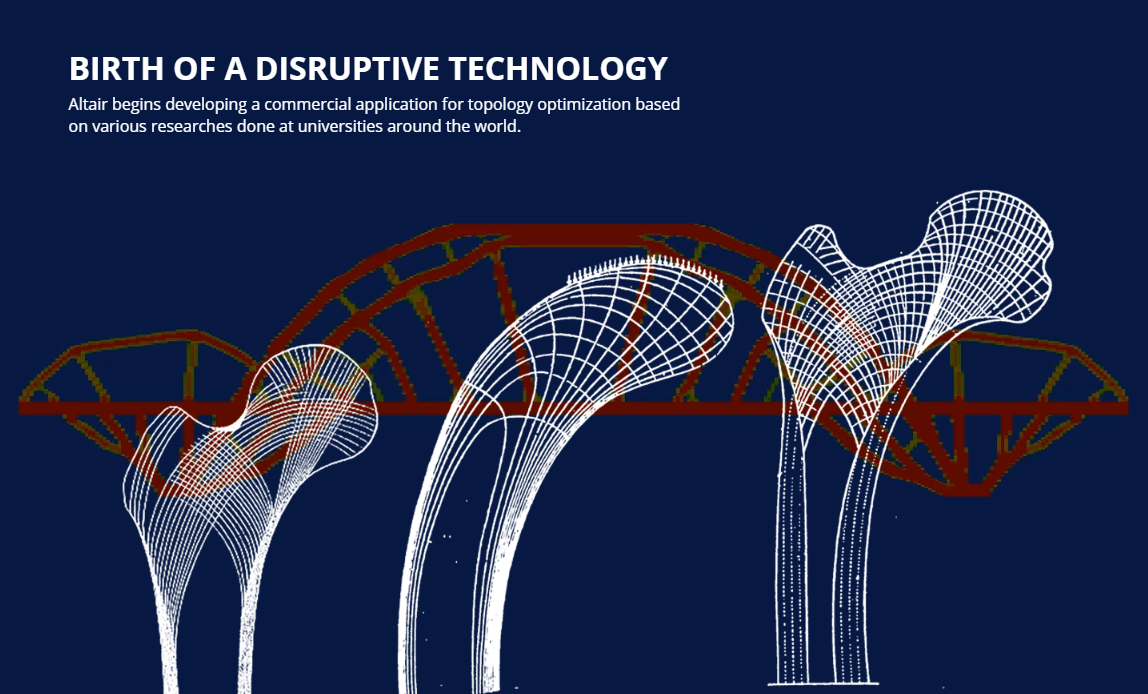

Altair’s Leadership in Generative Design

In 1990’s Altair begins developing a commercial application for topology optimization based on various research done at universities around the world. In 1994 Altair received “Technology of the Year” award for OptiStruct. Since then, Altair OptiStruct has proven to be the leading product for lightweight design in various industries with different applications such as world’s largest passenger airplane (saving 1100 lbs of takeoff weight), automotive shading weight from almost every component, helping doctors in creating 3D printed hip replacement with lattice structure, satellite parts to exceed design criteria with lightweight design, help athletes with futuristic gear to win competitions and many more. Altair Inspire uses OptiStruct as a solver, adding an easy to use interface especially for designers, architects and multitasking engineers.

Visit altair.com/optimization to learn how Altair has pioneered optimization solutions for its customers

Visit altair.com/optimization to learn how Altair has pioneered optimization solutions for its customers

New Licensing Model

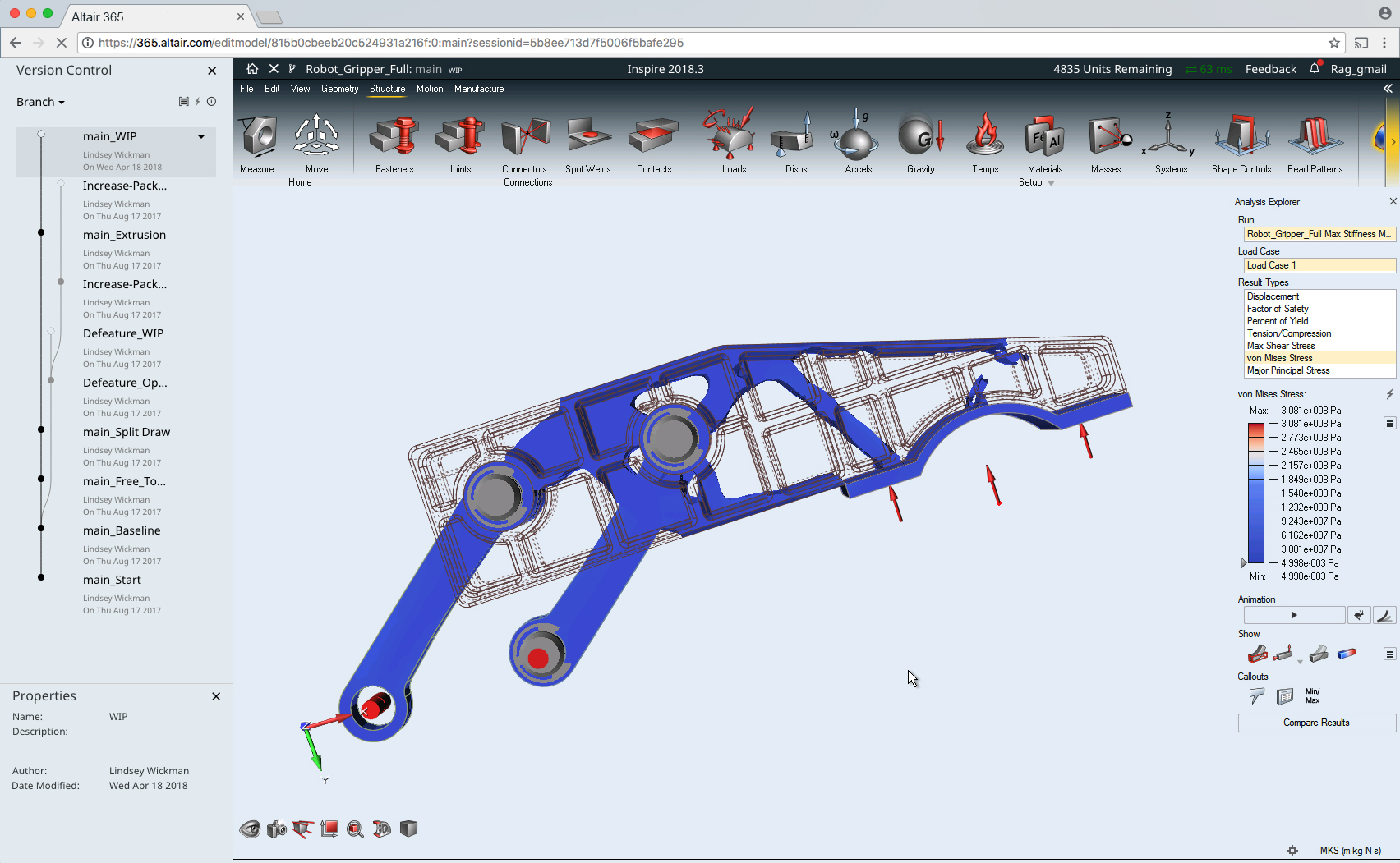

The all-new solidThinking units licensing model empowers users with access to all software titles available through the solidThinking suite as well as the ability to run these applications on-demand locally or in the cloud. Check out a special on-demand presentation featuring Altair Inspire now!

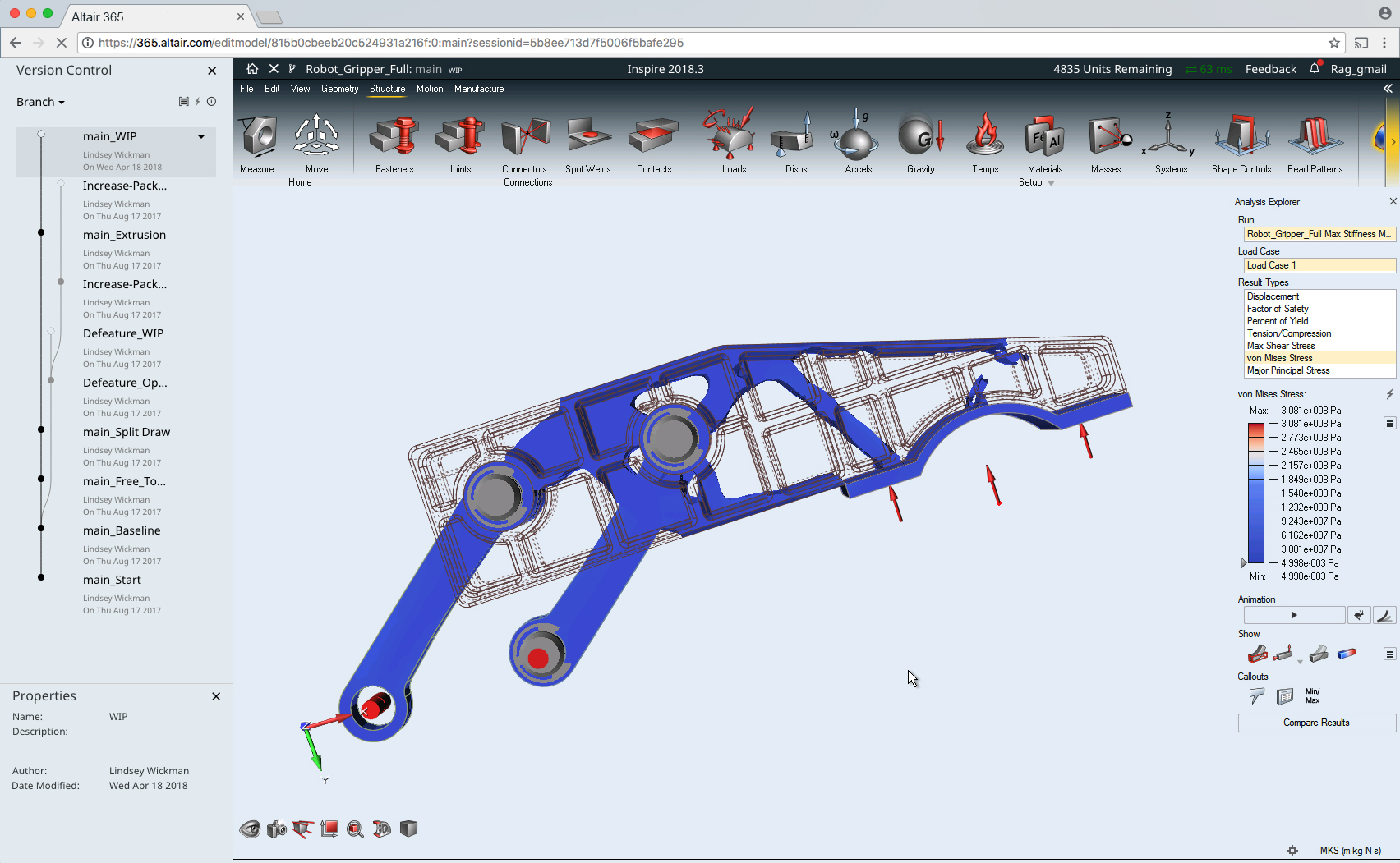

The Altair Inspire Platform is now available in the cloud via Altair 365

The Altair Inspire Platform is now available in the cloud via Altair 365

Where Innovation Begins

Altair Inspire is a software platform that enable designers and design engineers to generate the most efficient concepts with focus on performance and manufacturability. This leads to reduced costs, shortened product development time, minimal material consumption and lightweight design.

Simulation-driven Design

We all designed parts the old way, in silos or throwing designs over the wall to get analyzed. And after many iterations finalize a design. Meanwhile much of a time, money and productivity is lost. Wait…we haven’t started discussion on manufacturing methods, and how design will affect tooling, machining, 3D printing or other manufacturing options for this design.

Applying a simulation-driven design approach, the Altair Inspire platform answers these exact problems in the design process. Early simulations in the product development process such as Finite Element (FE) analysis, kinematic and dynamic motions, design optimization, and manufacturing processes drive how design should be while satisfying all structural design criteria.

Additive and traditional manufacturing processes, like the casting simulation shown here, are supported

Additive and traditional manufacturing processes, like the casting simulation shown here, are supportedManufacturability

Altair Inspire allows users to assign manufacturing constrains for both traditional and additive manufacturing processes. One can select method to create a design for casting, or machining or create a design to take advantage of the additive process. It’s easy to control overhang angles to reduce or eliminate support structure requirement during 3D printing. It also helps users to find out best orientation for the part given 3D printer specifications. Design comparison features helps engineers make intelligent design decisions using qualitative and quantitative data.

Then engineers can quickly run manufacturing feasibility simulation on newly generated design concept. Also run detailed casting, forming, or extrusion simulations to determine if a design fits for the specific manufacturing process.

Altair’s Leadership in Generative Design

In 1990’s Altair begins developing a commercial application for topology optimization based on various research done at universities around the world. In 1994 Altair received “Technology of the Year” award for OptiStruct. Since then, Altair OptiStruct has proven to be the leading product for lightweight design in various industries with different applications such as world’s largest passenger airplane (saving 1100 lbs of takeoff weight), automotive shading weight from almost every component, helping doctors in creating 3D printed hip replacement with lattice structure, satellite parts to exceed design criteria with lightweight design, help athletes with futuristic gear to win competitions and many more. Altair Inspire uses OptiStruct as a solver, adding an easy to use interface especially for designers, architects and multitasking engineers.

Visit altair.com/optimization to learn how Altair has pioneered optimization solutions for its customers

Visit altair.com/optimization to learn how Altair has pioneered optimization solutions for its customersNew Licensing Model

The all-new solidThinking units licensing model empowers users with access to all software titles available through the solidThinking suite as well as the ability to run these applications on-demand locally or in the cloud. Check out a special on-demand presentation featuring Altair Inspire now!

The Altair Inspire Platform is now available in the cloud via Altair 365

The Altair Inspire Platform is now available in the cloud via Altair 365