Digital Engineering: Charting the “Phygital” Frontiers with Digital Twins

Paul has a morning ritual. As he sips his first cup of coffee, he takes a walk around his silver-grey V8 automobile, peeking under the hood for potential signs of trouble before they arise. While Paul swears by the utility of his routine, his 10-year-old twins John and Linda are annoyed because the daily inspection drive usually means they’re late for school.

What Paul does is like the legacy approach towards physical asset management, which involves an active monitoring schedule that identifies potential signs of failure and reacts to those scenarios. While the approach has its benefits, it’s also time-consuming, tedious, and more expensive.

Transcending the Phygital Frontiers: Enter Digital Twins

“Phygital” – the amalgamation of physical and digital solutions – isn’t a new concept. As the world realizes phygital’s possibilities, we’re witnessing the rise of countless phygital offerings, including the ubiquitous digital twins.

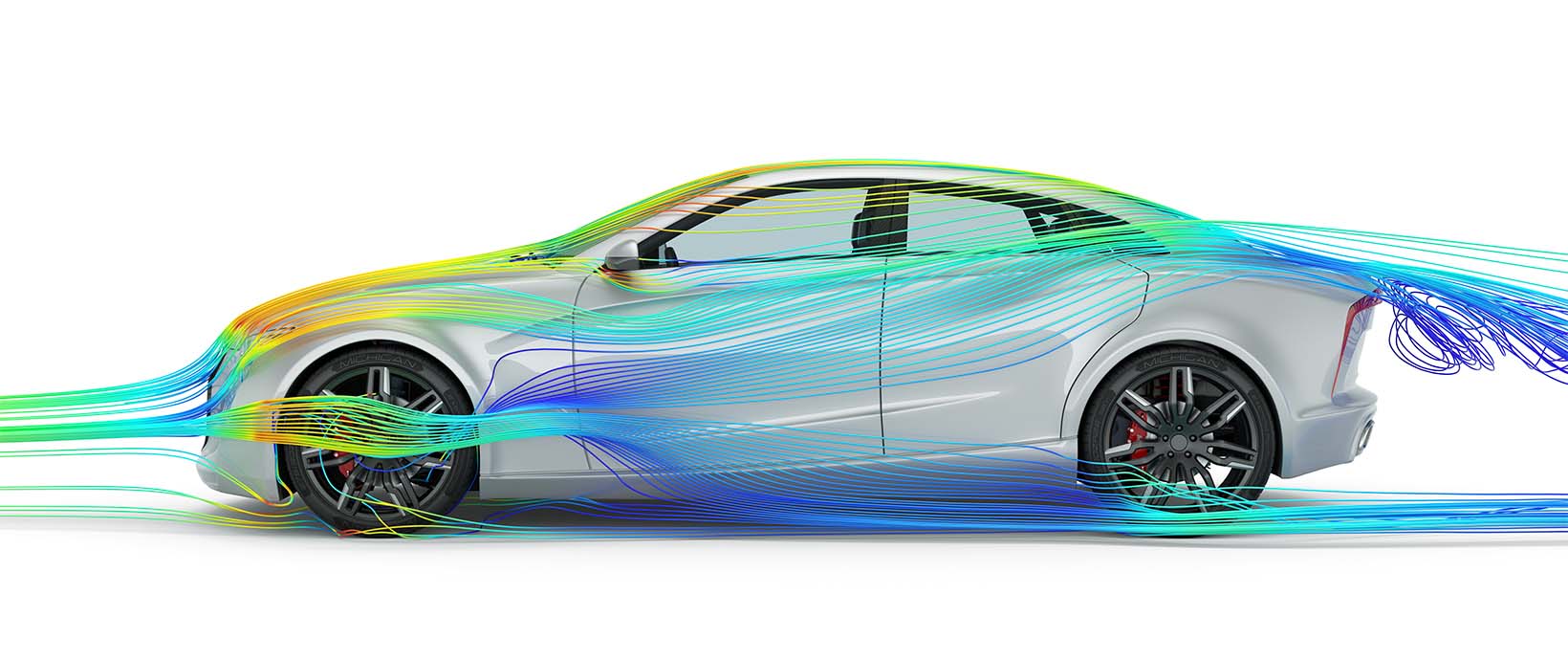

Generally, a digital twin setup involves the creation of a physical product’s virtual alter ego, which could be a wind turbine, a locomotive, an entire factory, or even Paul’s car. Note that not all digital twins model physical products (twins in the financial sector, for instance, can model processes or personas), but it’s easier to visualize examples with physical products.

In an increasingly hyperconnected global ecosystem, digital twins are already playing a key role in driving design, manufacturing, validation, testing, and improvement paradigms, and are ensuring faster time to market with reliable outcomes. Its major benefits span across delivering efficient supply chain management, streamlined predictive maintenance schedules, enhanced quality control, rapid identification of bottlenecks, and lean six sigma – contributing to the sustainable development of industries.

The LTTS-Altair Partnership: Accelerating Digital Engineering

L&T Technology Services (LTTS) leverages significant multi-industry expertise and deep cross-domain capabilities to identify customer challenges and create and implement relevant digital twin solutions for redressal. We have established a Digital Twin Center of Excellence (CoE) to address and accelerate the digital twin and digital thread requirements of new-age manufacturing companies, helping ensure leaner operations, faster decisions, and optimized costs.

The CoE’s charter covers:

- Manufacturing: Shop floor performance improvement, predictive maintenance, plant-level system analysis, intelligent safety, and human resource management;

- Automotive: Design customization, thermal management of electrical vehicles, battery management, and system level modeling;

- Industrial products: Life prediction, conditional monitoring, design optimization;

- Retail: Customer modeling and simulations;

- Healthcare: Anomaly detection, remote surgery, and customized medications;

- Telecommunications: Signal strength and coverage, tower infrastructure layout, structural strength evaluation, and remaining life estimation and prediction; and

- Supply chain management: Optimizing warehouse design, and improved logistics networks.

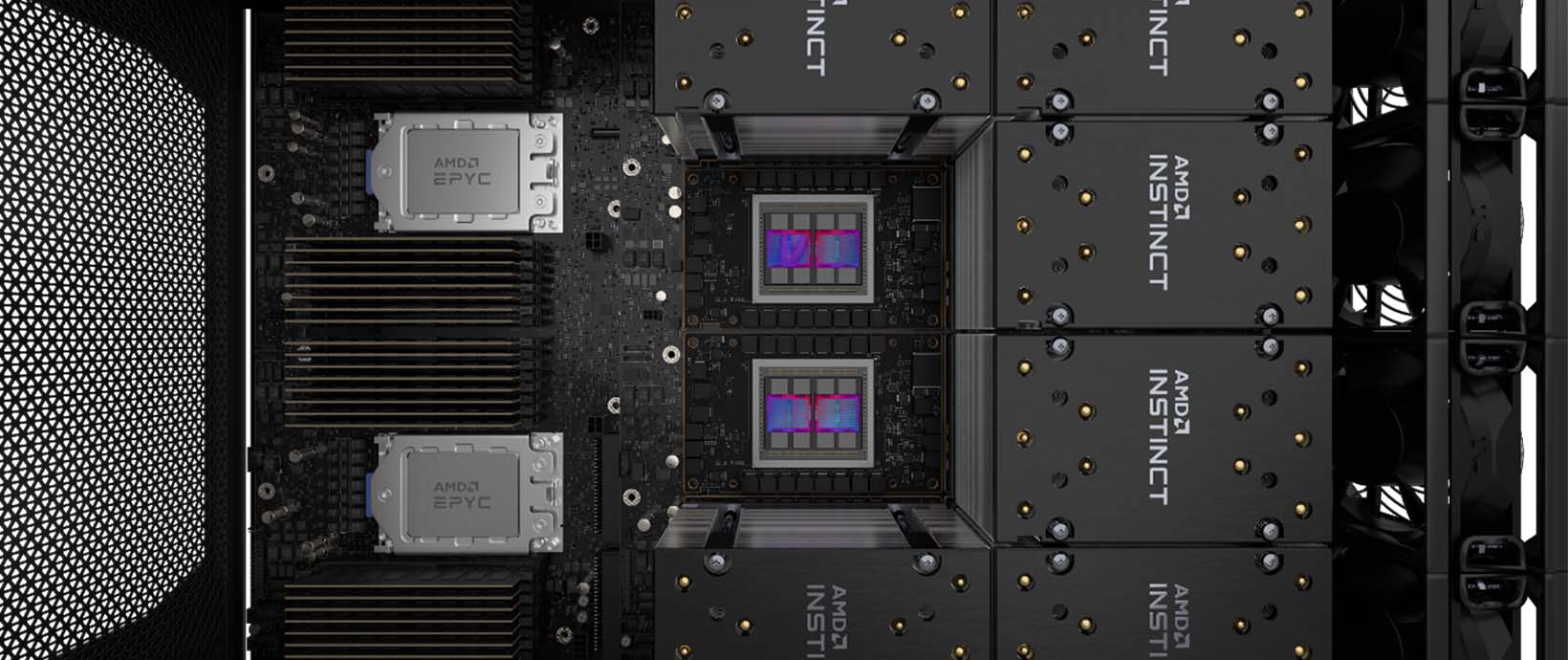

To further augment and strengthen our digital twin portfolio, LTTS has partnered with Altair to leverage best-in-class platforms and solutions to help customers in their product evolution journey, starting from digital twin prototypes and onwards to smart digital twins. Altair’s capabilities in data analytics, multi-physics, and large data handling with cloud artificial intelligence (AI) and machine learning (ML) help drive the creation of digital twins for various industries.

The partnership empowers LTTS’ customers with access to a comprehensive suite of Altair solutions, including but not limited to:

- RapidMiner: An advanced ML and AI platform for model building and enterprise data analytics.

- Altair Activate®: A flexible integration platform for comprehensive system-of-systems simulation.

- Altair Embed®: A powerful tool for nonlinear simulation and model-based firmware development.

- Altair® Panopticon™: A comprehensive data visualization and streaming analytics tool.

LTTS and Altair are therefore complementing each other in their expertise, creating a win-win scenario for their customers around the world.

And let’s not forget that the twins John and Linda are quite happy now since they’re on time for school these days – the digital twin of the family car has liberated them from the boredom and tedium of Paul’s morning routine!