Digital Debunking: Can Discrete Element Modeling Maximize Your Halloween Candy Haul?

Autumn features many timeless traditions, including one of the most popular of them all in the United States (and elsewhere): Halloween! Halloween is a thrilling time of the year for children and adults alike as they prepare their best costumes and get ready to collect (hopefully) mountains of candy during trick-or-treating.

However, behind the fun, trick-or-treating is all about strategy (as any kid can testify). Some children choose speed, making a mad dash for high quantities of candy, knocking on as many doors as possible. Others like the slow and steady approach, targeting only houses that give out the biggest rewards – like full-size candy bars. Children will also strategize which houses give the best treats, calculate how many houses they can visit, and estimate the sheer volume of candy they'll collect. By the end of the night, they’ll eagerly sort through their haul.

But this got us thinking – with a more focused strategy, can Altair’s discrete element modeling solutions maximize your Halloween candy haul?

Developing the Trick-or-Treat Bucket

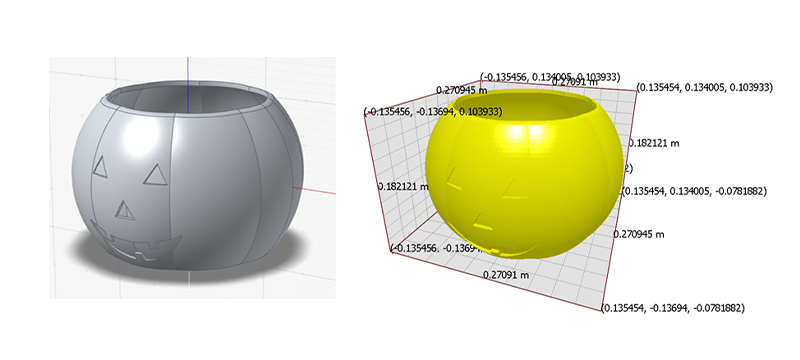

Before we got started, any good trick-or-treater knows you have to select the right candy receptacle. As such, we started by creating a model of a traditional pumpkin bucket within Altair® Inspire™ Studio (Figure 1). Inspire Studio allows users to create, evaluate, and visualize designs quickly and efficiently with no limitations while working with concave polyhedral particles (like the pumpkin bucket).

The bulk materials were created and assigned to the respective particles within Altair® EDEM™. If you want to maintain a certain shape with the best definition possible or maximize the computational efficiency of the simulation, you can increase or reduce the number of elements by performing simple meshing within Altair® HyperMesh® or modifying the input settings in EDEM. Less elements mean faster calculations, while more elements improve shape definition.

Determining Candy Shapes

Once we determined the candy bucket’s shape and size, we then moved on to modeling the candy itself. To do so, we ran three separate simulations and compared the results of different candy combinations:

- Both candy types mixed

- Only chocolate candies

- Only non-chocolate candies

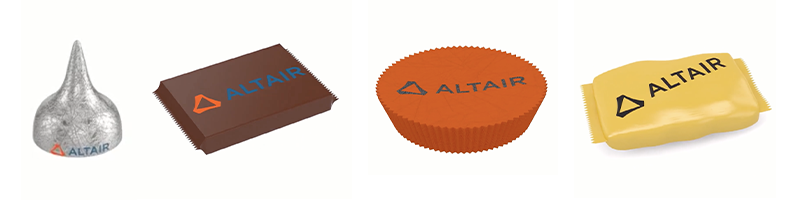

We used five candy shapes to maintain consistency during testing while providing enough variety to mimic the random assortment of candy children receive while trick-or-treating (Figures 3/4). With EDEM, complex particle shapes can easily be created and simulated with full resolution. We sorted the simulated candies into the following categories:

- Chocolate candy: Such as Hershey’s Kisses, mini chocolate bars, Reese’s peanut butter cups, and M&Ms

- Non-chocolate candy: Such as Starbursts, peppermints, and other wrapped circular candies

The four factors we considered when comparing which strategy would maximize the amount of candy a trick-or-treater could take home spanned:

- Bulk density

- Number of candies

- Total mass of candies

- Solid fraction achieved in the bucket

Bulk density is a measure of the mass of candy per bucket unit of volume, including the volume of any space between particles. The bulk density depends on how well candy packs into the pumpkin trick-or-treat bucket. The higher the bulk density value, the less empty space there is, and therefore more candy can fit inside the bucket. Similarly, the solid fraction refers to the proportion of a material's volume that is occupied by solid particles, as opposed to voids or spaces between particles.

Running the Simulations

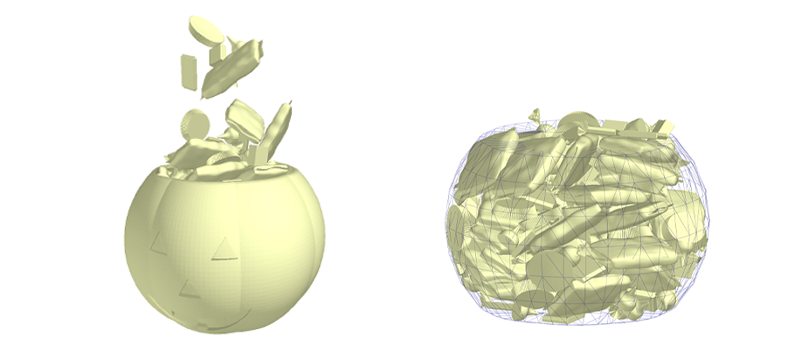

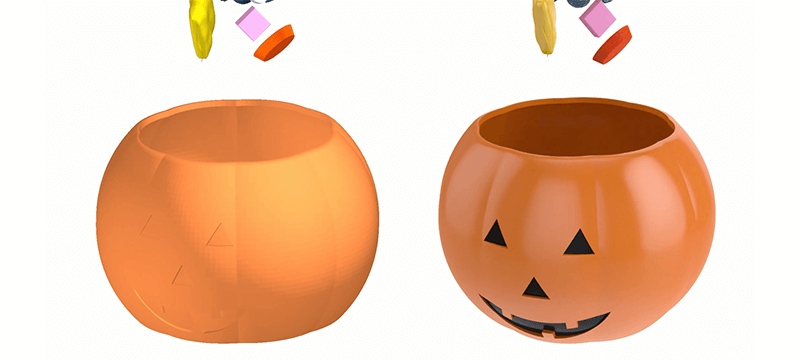

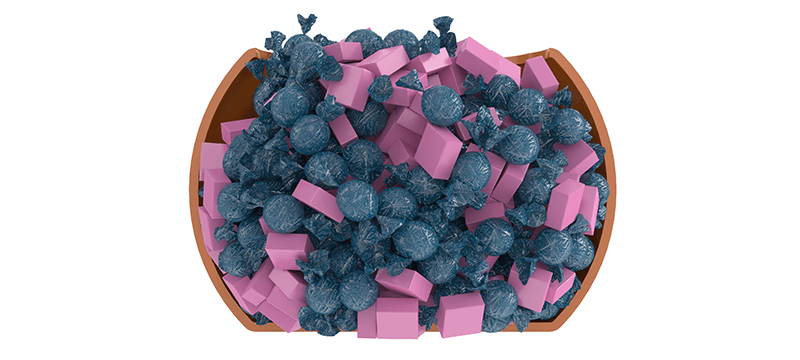

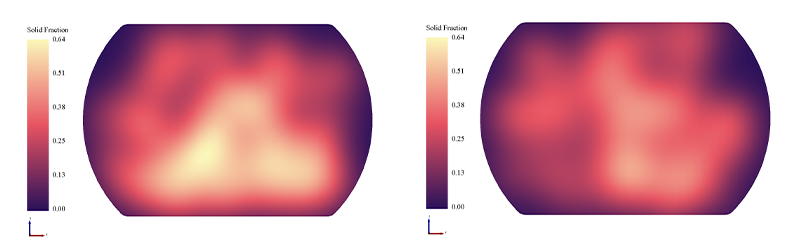

The simulations were initally run using EDEM to understand and predict material behaviors, in this case, delicious Halloween candy. The images captured from EDEM simulation (Figure 5) were then used in Inspire Studio to obtain a high quality rendering of each simulation (Figure 6).

Figure 5: Traditional pumpkin trick-or-treat bucket and candy model created in EDEM

Figure 6: Comparison between EDEM simulation results (left) and Inspire Studio rendering based on EDEM data (right)

The first simulation included all mixed candy types, generated in roughly equal amounts. This replicates a realistic trick-or-treating experience where candy types vary from stop to stop.

Figure 7: Simulation of all candy types mixed filling the bucket

Totaling 201 candies and a mass of 2.07 kg, this mixed-candy bucket resulted in a bulk density of 1,039.3 kg/m3. The mini chocolate bars and Starbursts were the most collected, while taking up the least space.

The second simulation consisted of only chocolate candy.

Figure 9: Simulation of chocolate only candy filling bucket

Totaling 150 candies and a mass of 1.75 kg, the chocolate-only bucket resulted in a bulk density of 997.1 kg/m3. There was an even distribution amongst chocolate candy types with the smaller Hershey’s Kisses and mini chocolate bars occupying the least amount of space.

The final simulation consisted of only non-chocolate candies only. These candies are usually smaller and more rigid than chocolates.

Figure 11: Simulation of non-chocolate candy filling bucket

Totaling 463 candies and a mass of 3.53 kg, the non-chocolate candy resulted in a bulk density of 1,236.2 kg/m3, besting the totals of both the mixed and chocolate-only buckets.

Findings

When comparing simulations, we see a larger amount of the non-chocolate candy fits in the bucket both in terms of pieces and mass. They consist of smaller, simple shapes which allow them to pack efficiently and thus minimize unused space within the bucket. The opposite occurred with the chocolate-only simulation; since these treats’ packaging is larger and less dense, they don’t pack as efficiently within the bucket. The final totals, in order:

- Non-chocolate candy only: 1,236.2 kg/m3 (463 candies at 3.53 kg)

- Mixed candy: 1,039.3 kg/m3 (201 candies at 2.07 kg)

- Chocolate only: 997.1 kg/m3 (150 candies at 1.75 kg)

If the goal is to maximize the quantity of your trick-or-treating haul this Halloween, then aim for non-chocolate candies. However, if you like variety and want to include chocolate in your candy consumption, then it’s important to strategize candy placement. During trick or treating, it’d be worth stopping in between houses to give the bucket a gentle shake to help the candy rearrange and pack more efficiently to free up more space for additional goodies.

Conclusion

If you want all types of treats this holiday season, then layering candy based on shape and size – along with periodic bucket shaking – will maximize your trick-or-treating haul. This will give you the highest candy count and density within the bucket. Solid fraction visualization using continuum analysis generated from the discrete data of the EDEM simulation shows significant improvement of all the candy mixed when layered and shaken

When the first simulation of all mixed candy types was layered and shaken, it generated a bulk density of 1,109.5 kg/m3 (264 candies, mass of 2.55 kg), which we found was 6.75% better than not layering or shaking the bucket. The mini chocolate bars and Starbursts remained the most collected, while the Reese’s peanut butter cups added the least weight to the bucket.

With some strategy (and proof from Altair’s DEM software) you’re now equipped to optimize your candy haul this Halloween. Now grab your buckets and get out there – happy Halloween! To learn more about EDEM, visit https://altair.com/edem. To learn more about HyperMesh, visit https://altair.com/hypermesh. To learn more about Inspire Studio, visit https://altair.com/inspire-studio.