The Rise of Tall Wood Buildings

A world of tall wood building opportunities has emerged thanks to new mass timber building materials and updated design codes. Large wooden structures up to nine stories tall have existed since the early 1900s, but reinforced concrete and steel surpassed timber by midcentury as the material of choice for tall buildings – until now. Around the world, tall wood buildings used for residential, commercial, and institutional purposes are altering skylines and offering an eco-friendlier alternative to traditional construction materials.

Innovative technologies, such as cross-laminated timber (CLT), glued-laminated timber (Glulam), and structural composite lumber (SCL) mass timber products are stretching architects’ and engineers’ tall wood building imaginations and capabilities. Ongoing research also supports this trend by demonstrating that mass timber meets or exceeds safety, structural resilience, energy and durability requirements, and fire protection codes.

FPInnovations, a private, not-for-profit research and development organization supporting the Canadian forestry sector, is a source of technical knowledge for the mass timber design and construction community. Its recent publications for CLT design handbooks, design and construction guides for tall wood buildings, and its most recent publication, Modeling Guide for Timber Structures, provide structural engineers and designers with essential resources to help them adopt mass timber in their projects.

A multi-story mass timber building under construction. [KK Law, courtesy naturallywood.com]

What Constitutes a Tall Wood Building?

According to the Canadian Wood Council, any building over six-stories high that uses mass timber as part of its structural support system is considered a tall wood building. The tallest wood building in the U.S., Ascent, is a 25-story mixed-use structure that recently opened in Milwaukee, Wisconsin. In Canada, the tallest wood building is the 18-story Brock Commons Tallwood House completed in 2017 on the campus of the University of British Columbia.

CLT floor panel installation in tall wood structures. [KK Law, courtesy naturallywood.com]

Carbon Storage and GHG Emission Reduction

Wood buildings can significantly reduce greenhouse gas (GHG) emissions associated with traditional construction materials, contributing to carbon dioxide (CO2) reduction targets.

“A building built with concrete and steel typically has a high carbon footprint per unit. Embodied emissions are the emissions generated from the energy and material inputs required to make a given product,” said Patrick Lavoie, senior researcher of carbon and market economics at FPInnovations. “The inputs that have the highest emissions are for the cement used in making concrete. Cement requires very high temperatures for the calcination process, and fossil energy is typically used.”

Another beneficial aspect of tall wood buildings is they are a component of a renewable carbon cycle.

“As trees grow, they capture CO2 from the atmosphere and store carbon. That carbon is also stored in wood buildings and, unless it is recycled, is released into the atmosphere at the end of its service life with another cycle beginning,” Lavoie said.

Circular Economy

Wood products are also a component of the circular economy model that favors reusing, restoring, and recycling existing materials.

“The wood at the end of the service life of a building can be turned into other products, such as panels,” Lavoie said. “There’s still progress to be made on that front, but the industry is looking at additional ways to recycle wood products that are taken out of circulation.”

Durable, Sustainable Construction

Tall wood buildings can be designed with lifespans similar to those of steel and concrete structures, and the cost of building tall with wood is falling.

“Before COVID and going back five to 10 years, building with wood would cost a 3-5% premium,” said Dorian Tung, manager of building systems at FPInnovations. “That was partially due to the experience level of builders — there was more contingency built into quotes, but because of accumulated experience, the cost of building with wood is about the same as with steel and concrete.”

The building industry is slowly embracing the design for adaptability and disassembly approach to construction that is used to reduce obsolescence and the environmental impacts of consumption and waste. Building with wood lends itself to that approach. Elements are prefabricated, pre-cut, and drilled offsite then bolted and screwed together on work sites. In terms of disassembly, the sequence can easily be reversed, allowing people to repurpose the wood.

“It’s the adaptability aspect that’s in the initial stage,” Tung said. “We are seeing that it’s becoming a preference for public buildings such as schools. When clients begin asking that their buildings be adaptable to future needs, we will see real change.”

Timber Engineering and Technology

Tall timber structures are continually showing promise in feasibility and sustainability. With the rise of taller, larger, and more complex timber structures, there’s a need for more advanced and more efficient tools to help engineers design and predict these buildings’ structural behavior. Even though this technology is well established for conventional reinforced concrete and steel structures, timber structure analysis and design still requires a more streamlined and widely accepted process.

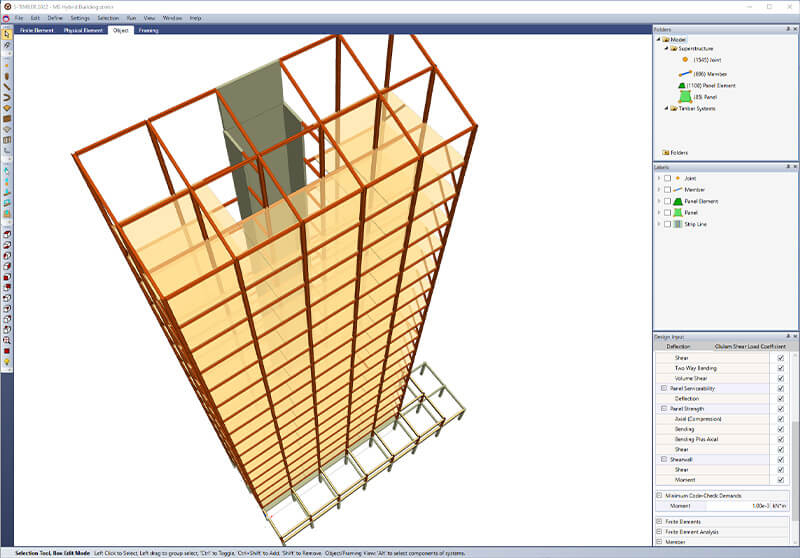

To aid this effort, FPInnovations has partnered with numerous industry sectors and private companies, including Altair, to develop a guide for modeling and analyzing timber structures using computer modeling and structural analysis aids. The modeling guide includes scientific background on the subject and provides technical guidance on how to properly model and analyze these structures. This technology sharing helps structural engineers understand and use simulation solutions like Altair® S-FRAME® and Altair® S-TIMBER™ for mass timber projects.

Hybrid Steel, concrete, and mass timber model in S-TIMBER

FPInnovations also works closely with Canada’s wood design code committee and helps establish up-to-date timber design provisions. To expand the use of timber in tall buildings and to improve timber frame design in seismic regions, FPInnovations is conducting studies and experiments to recommend Canadian design code improvements for the next version of the wood design code.

Altair’s architecture, engineering, and construction (AEC) team has collaborated with FPInnovations to perform analyses using Altair tools that examine design scenarios and perform proof-of-concept analyses with the aim of supporting suggested design code improvements. Altair’s structural analysis solver – backed by its wide industry acceptance – provides the means to perform these studies. The combination of S-FRAME and S-TIMBER enables the automated and iterative analysis and designs to generate supporting data for the suggested design code changes. Partnerships like these between FPInnovations and private industry solution providers will accelerate mass timber adoption and help commercial and residential building projects reach their sustainability goals.

With pressure for more environmentally friendly building materials and methods driving innovative architecture and building methods, mass timber buildings have a firm footing in the future of sustainable construction.

To learn more about Altair’s solutions for analyzing and designing sustainable structures, visit https://www.altair.com/structural-engineering.