Better Simulation of the Vibration Behavior of Structural Parts

This guest contribution is written by Dr. Wolfgang Korte, Managing Director at PART Engineering, developers of CONVERSE. PART Engineering is a member of the Altair Partner Alliance.

This guest contribution is written by Dr. Wolfgang Korte, Managing Director at PART Engineering, developers of CONVERSE. PART Engineering is a member of the Altair Partner Alliance.

It is important to consider the molding process for short fiber-reinforced plastic parts when conducting finite element (FE) analysis of such parts. The frequently used method of isotropic analysis with a globally “smeared” stiffness in the part using reduction factors leads to large uncertainties. The additional work necessary for the integrative simulation approach is reasonable by comparison with the gain in precision and the resulting higher assessment security.

However, the specific material behavior of thermoplastic polymers in general, and of short fiber-reinforced grades complicates the analysis. Key parameters here are the anisotropy of the material behavior resulting from the fiber orientation and the damping of the material.

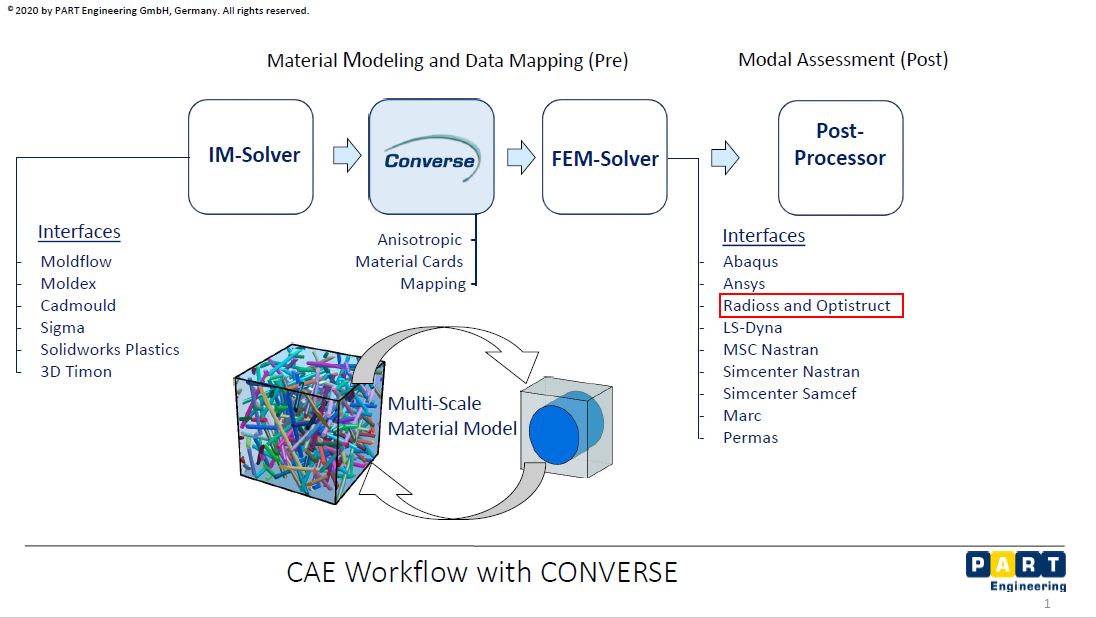

As the properties of components made of a short fiber-reinforced polymer have a certain dependence on the fiber orientation, a holistic consideration using integrative simulation is necessary for a precise computational assessment. An injection molding simulation may provide the needed local fiber orientation in the component. With CONVERSE, the fiber orientation is obtained from an injection molding simulation and a multi-scale material model is applied to take account of the influence of the fiber orientation on the mechanical properties of the component (Figure 1).

Figure. 1: CAE workflow with CONVERSE

These models allow the behavior of the composite to be calculated on the basis of the material properties of its constituent parts, like matrix polymer and reinforcing fibers. As a micro-scale model is not feasible for macroscopic parts, homogenization methods are used.

The homogenization method computes the anisotropic properties of the composite on the basis of the mechanical properties of its constituents and their spatial configuration without the need for micro-scale modeling of each constituent. In this way for each element in the FE model a particular material behavior is considered. For the calibration of the material model, like quantitative determination of the model parameters, experimental tests were performed.

For this, examples were taken at different angles to the flow direction from injection-molded test plaques and tested in short-term tensile tests. Additionally, we performed flexural vibration tests in order to determine a frequency-dependent model damping factors.

Validation on the part

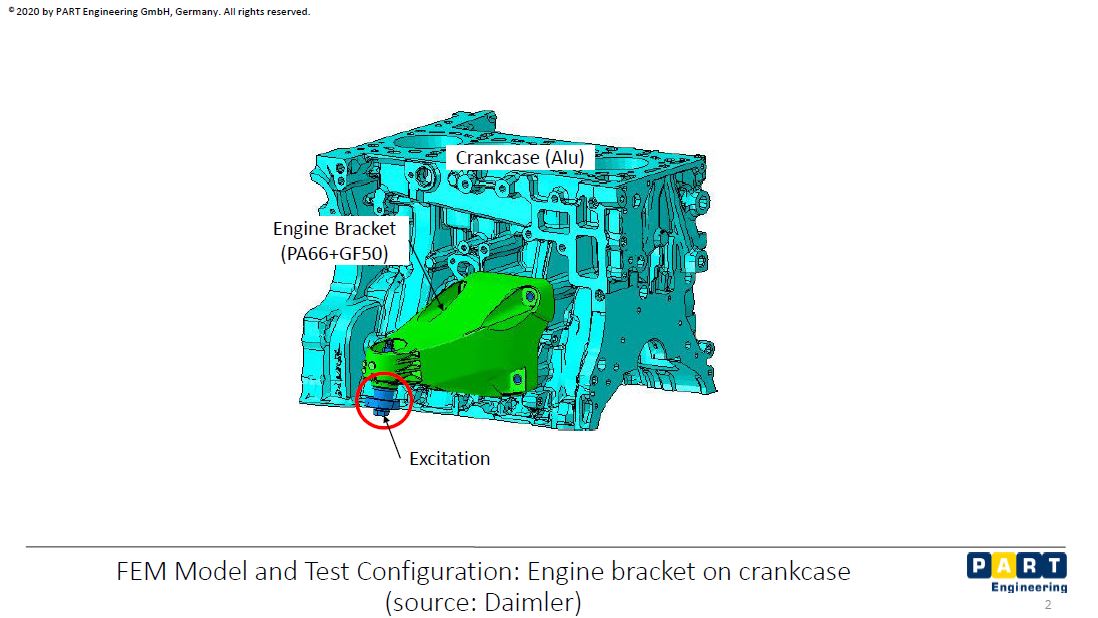

The simulation results were validated experimentally on the automobile engine bracket made of a polyamide with 50% glass fibers. The engine bracket was mounted on an aluminum crankcase (Figure 2).

Figure 2: FEM model and test configuration of the engine bracket on crankcase (source: Daimler)

The vibration response was recorded using a 3D scanning laser vibrometer. The acceleration over the whole component surface was measured. This revealed the natural frequencies, natural modes and the response behavior.

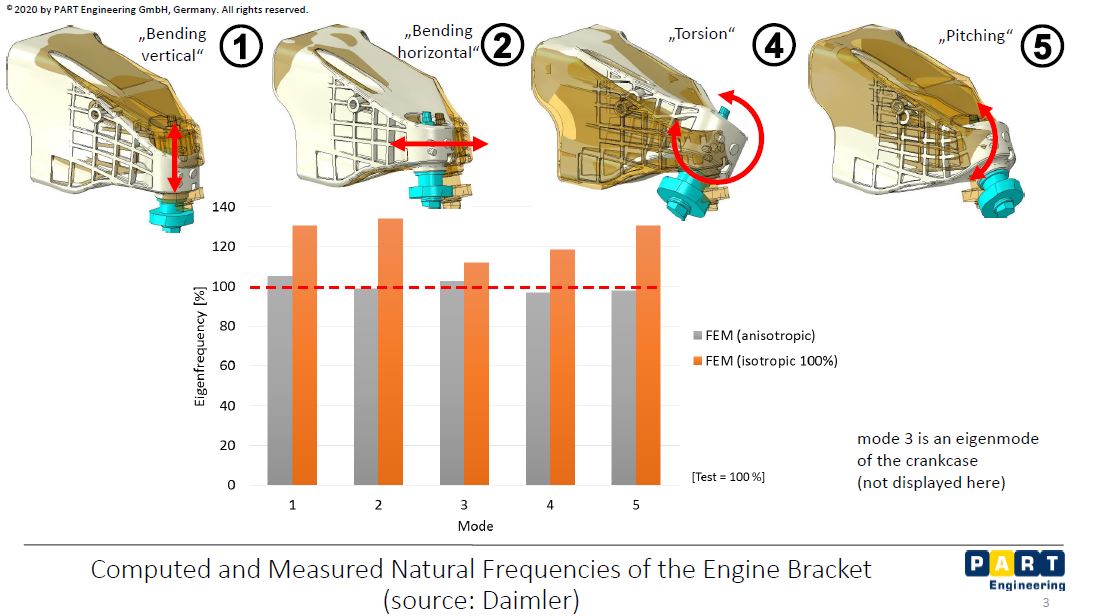

In figure 3 the results of an isotropic FE analysis also performed without making allowance for the fiber orientation are compared in standardized form: 100% correlate with the measurement.

Figure 3: Computed and measured natural frequencies of the engine bracket (source: Daimler)

The relative deviations between computed and measured natural frequencies for the anisotropic simulation lie between 2% and 5%, whereas deviations of between approximately 20% to 34% compared with the test are observed for the isotropic simulation. The isotropic analysis computes the natural frequencies significantly too high. The visual evaluation of animations of the natural modes in the comparison between measurement and simulation shows also a very good correlation.

Excellent tradeoff between accuracy and effort

The fairly simple description of the material behavior using an anisotropic linear-elastic material model and a global frequency-dependent damping factor results in a good prediction of the vibration behavior in relation to the measurement. More elaborate material models (like viscoplastic models) do not neccessarily result in more precise simulation results. It has to be kept in mind that for FE analysis in the frequency domain a linearization takes place anyway and displacements and strains are small.

The pre-homogenized material cards generated by CONVERSE allow the use of solver-builtin standard material models so that the FE analysis is efficient, numerically stable and fast. Hence the application is also suitable for large models. CONVERSE is an easy-to-use software, it allows the practice-oriented application of the workflow described here even for occasional non-expert users.

CONVERSE can be accessed through the Altair Partner Alliance. For more information, view the on-demand webinar.