Developing Miniature Circuit Breakers with a Multi-Disciplinary System Design Approach

Schneider Electric is leading the digital transformation of energy management and automation in homes, buildings, data centers, infrastructure, and industries. With 150,000 employees worldwide and a global presence in over 100 countries, Schneider is the undisputed leader in power management and automation systems. In addition, Schneider Electric offers IoT-enabled solutions to seamlessly connect, collect, analyze and act on data in real-time. Providing integrated solutions, Schneider Electric helps customers better manage their energy systems to achieve higher energy efficiency and sustainability.

An Altair customerfor many years, Schneider Electric at first used only Altair Flux™; now the company has extended their usage to several more software products in the Altair HyperWorks™ suite, including solutions such as Activate, MotionSolve, OptiStruct, and others to apply co-simulation in their development processes. Schneider feels their collaboration with Altair is more like a partnership than the standard supplier-OEM relationship. “Our technical feedback is truly heard and promptly acted upon,” said Stephane Follic, Actuator team leader at Schneider Electric. “Beyond the pure technical value we obtain by using the Altair tools, we also derive significant business value from working with Altair. Their tools and support help us improve product quality, accelerate our development cycle, and reduce risk pertaining to product performance.”

Realizing new market opportunities with an ultra-short time-to-market goal

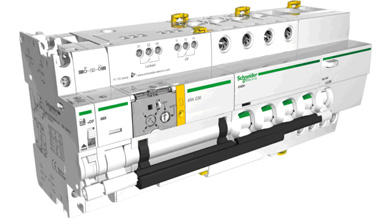

Recently, Schneider Electric had the opportunity to pursue a new circuit breaker business in a geographic market in which they were not yet present. For this, they had to develop a product variant that would meet all-new specifications, including operating conditions which differed from the standard operation, involving different voltage levels and types (DC rather than AC). Since the window of opportunity was short, the challenge was to develop a viable product within only four months. Schneider Electric turned to simulation technology to speed the process and meet the development deadline.

Multi-disciplinary design approach with the Altair HyperWorks suite

For this circuit breaker project, Altair's flexible access to a wider range of CAE tools came in very handy, as electromagnetic, mechanic, control strategy, and other requirements needed to be considered at the same time. This multi-disciplinary design approach – based on use of Flux, MotionSolve and Activate together, including through co-simulation – allowed Schneider Electric engineers to evaluate numerous variants and identify the optimal design parameters for the various operating conditions.

“Altair’s global Licensing system makes a big difference for us. With other current vendors, we need to request trial licenses for their different tools to evaluate if our desired computations and workflows will indeed be suitable. In which case, normally, we would need to pay for these tools. With Altair’s Licensing approach, based on non-consumable tokens, we can test and use different products or workflows with low or no additional cost," said Leopoldo Martinez Garrido, CAE and 3D simulation manager at Schneider Electric. By combining 1D and 3D models, Schneider was able to successfully simulate their circuit breaker as the complete system-of-systems that it is. Activate enabled the engineers to model their control strategy and electronics disciplines. These results were then combined with the 3D models from Flux and MotionSolve.