Altair is Making Headlines with the Light Rider Motorbike

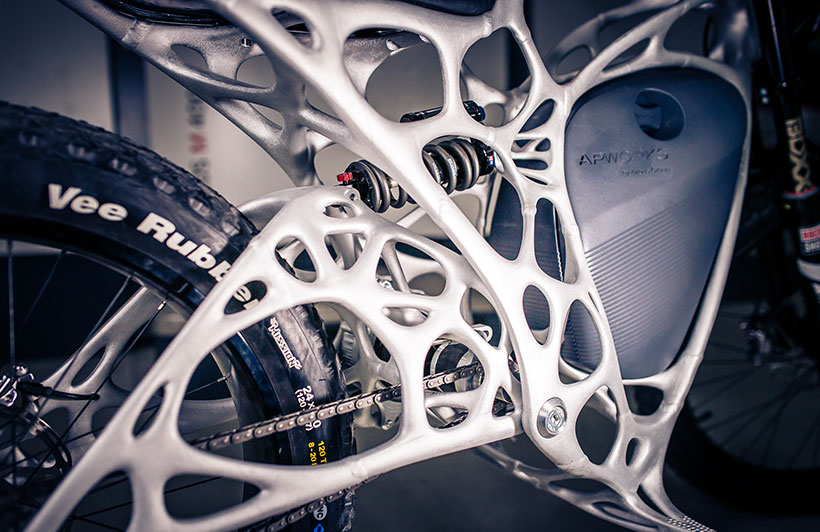

The November issue of the German publication "Digital Engineering Magazin" is fresh off the presses, featuring Altair on the cover. Digital Engineering highlights the story about the development of the Airbus APWorks "Light Rider", the world's first electrical motorcycle prototype. APWorks engineers applied Altair's HyperWorks® software suite using a simulation driven design process to design and develop the Light Rider's bike frame. The frame's structure is based on optimization results generated with Altair's OptiStruct® technology, supported by HyperMesh® for pre-processing tasks such as meshing, and HyperView® for post-processing the analysis results.

The November issue of the German publication "Digital Engineering Magazin" is fresh off the presses, featuring Altair on the cover. Digital Engineering highlights the story about the development of the Airbus APWorks "Light Rider", the world's first electrical motorcycle prototype. APWorks engineers applied Altair's HyperWorks® software suite using a simulation driven design process to design and develop the Light Rider's bike frame. The frame's structure is based on optimization results generated with Altair's OptiStruct® technology, supported by HyperMesh® for pre-processing tasks such as meshing, and HyperView® for post-processing the analysis results.

In a typical topology optimization run, the user first defines the design space (areas where the optimization technology can and cannot adjust the geometry, such as fixing points or access holes) and applies general loads and boundary conditions. Optimization goals are defined such as a minimum weight or maximum stiffness while simultaneously fulfilling certain requirements regarding target weight, stiffness, stress, or eigen frequency etc. OptiStruct then creates design proposals that fulfill these requirements, generating highly innovative geometries that follow the principles of bio-mimicry.

The APWorks engineers followed this process, also known at Altair as "Simulation-driven Innovation", when they created the design of the 3D printed Light Rider frame. They used the outer dimensions of the bike as their design space and added all known loads and contact points of the component. OptiStruct then calculated the optimal load curve and told the engineers where material had to be placed in order to also assure a minimum mass design, while simultaneously meeting the required stiffness characteristics. In a following redesign the optimization results were refined to receive a printable and appealing geometry, which was once again validated with OptiStruct via an additional finite element (FE) analysis to confirm the required stiffness.

The load cases that were to be used in the optimization came from literature in which typical load cases for motorcycles are documented. They include the driver sitting on the bike's seat or standing on the foot rests. Additionally, they applied further load cases that might influence the frame such as those coming from loads on the tires, friction or acceleration.

The Light Rider has proven to be an excellent example of the symbiosis of topology optimization and additive manufacturing that fully benefits from all weight and performance potentials additive manufacturing offers. The results speak for themselves. In addition to a very appealing design, the Light Rider, being the first 3D printed motorbike ever, is 30% lighter than a motorcycle with a traditionally manufactured bike frame. The bike frame weights 6kg, with the overall weight of the bike being 35 kg.

Learn more about Altair HyperWorks solutions for additive manufacturing and check out the Light Rider in the latest German Digital Engineering Magazin.