Dynamic Models and the Digital Twin at the Heart of the Schneider Electric R&D Strategy

How can we face the 80% electric consumption increase that will occur in the next 25 years? How can we mix existing apparatus in the infrastructure with modern smart equipment offering a maximum of energy flow flexibility to the grid? How can common technology like a circuit breaker, developed in the 30’s evolve to offer more value to its users in the future?

During his presentation at the Altair 2017 EATC Germany, Mr Gael Salles from Schneider Electric demonstrated ‘The Secret Life of Models’ and illustrated how they managed to transform relatively common products like circuit breakers into innovative solutions at the heart of the company strategy.

During his presentation at the Altair 2017 EATC Germany, Mr Gael Salles from Schneider Electric demonstrated ‘The Secret Life of Models’ and illustrated how they managed to transform relatively common products like circuit breakers into innovative solutions at the heart of the company strategy.

Beginning with steel factories in the 19th century, Schneider Electric progressively moved into electricity, and has over the years, grown into a global leader in energy management and automation through ongoing innovation. In the early 2000’s, anticipating market transformation, with strategic orientation, they addressed future energy requirements of industries and individuals.

Energy efficiency: a global challenge being addressed by Schneider Electric is addressing. Photo courtesy Mr Salles presentation

Energy efficiency: a global challenge being addressed by Schneider Electric is addressing. Photo courtesy Mr Salles presentationFrom relatively simple devices to smart connected devices, the Schneider Electric R&D team had to adapt their design process. Efforts to integrate increasingly complex technology - microcontroller, programs and communication capabilities – enabled them to offer new valuable features such as remote measurement, operational assistance or communication skills, and globally digitalize their products and services.

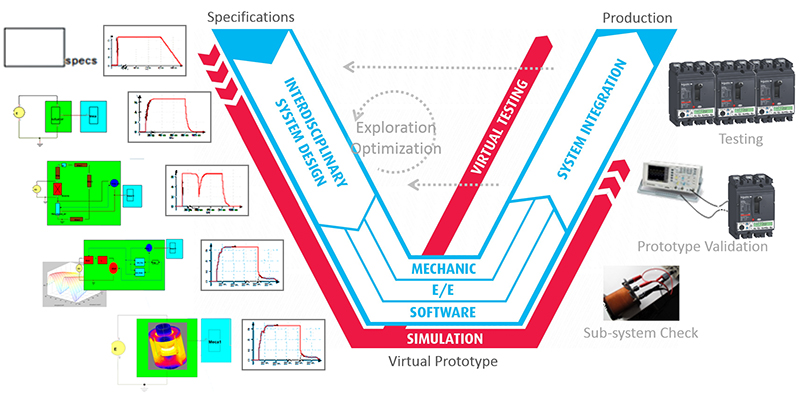

Intensively developing abstract models and efficiently taking maximum advantage of the V-Cycle methodology and interaction between subsystems, and placing them both at the center of their development life cycle, has definitively been a key to their success.

***

"The addition of Flux into the Altair suite is a great opportunity because year after year we bring more complexity into our product and accessing a complete suite of software will help us to simulate the global behavior of the system. I think it’s a game changer because it makes more savings in terms of development time, and motivates us to push the simulation beyond what we usually do.”

Remy Orban, Mechatronic Designer, Schneider Electric

***

Enlarging the design space

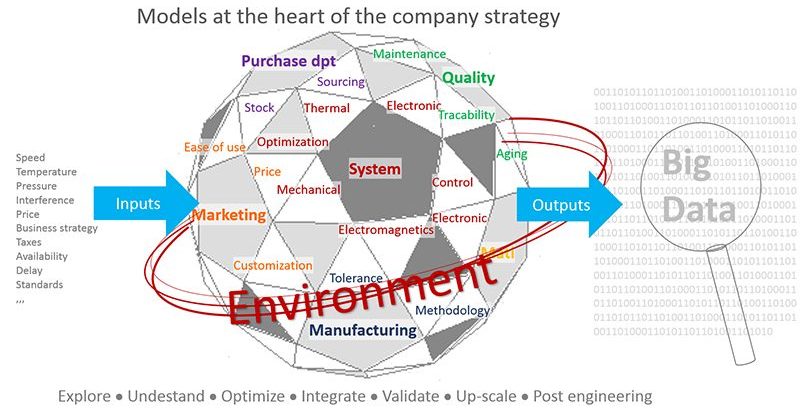

Designers may think in term of physics, the Purchase department may focus on reliability of sourcing, the Quality department on tractability, and the Sales team on product customization. Beyond the physical product, models offer the advantage of being able to consider their global environment but the design becomes much more challenging and requires efficient tools and methods to succeed.

Modern simulation tools and increased computing resources enables the creation of complex models, taking into account lots of I/O parameters. However, the challenge still remains in a more global workflow of implementing a shared view with an efficient simulation process, and in gaining insight into the massive results obtained.

Integrating technologiessolidThinking Activate® system simulation software offers a robust and efficient platform for integrating technology. It was developed as an intuitive block diagram environment to support model based development. It contains a canvas for building block diagrams representing real physical systems, a library of blocks and numerical integrators to perform simulations.

With the advent of Modelica and its physics-based approach and newly introduced FMI/FMU protocols, Activate enables users to compose complex multidisciplinary systems in one environment. Altair’s rich family of time-based, nonlinear solvers, including multi-body simulation (MotionSolve®) is now available as FMU blocks and any system model can be associated with them. In addition, a special FluxTM block can be used to include detailed electromagnetic models.

Exploring new horizonsPeople involved in global design need appropriate tools and methods in order to generate meaningful smart data and solvable scenarios.

Altair HyperStudy®, HyperWorks’ multi-disciplinary design exploration, study and optimization software helps designers get more smart data and leverage it for more knowledge. Using design-of-experiments (DOE) and optimization methods, HyperStudy creates a set of smart designs, automatically evaluates these designs and collects data. Designers are then guided to understand data trends, perform trade-off studies and optimize design performance and reliability. HyperStudy’s seamless connection to any HyperWorks solver enables quicker process automatic. DOE could be used to get a hierarchical ranking (highest to lowest) of inputs on outputs, and possibly screen out small-weight parameters. The HyperStudy Global Response Surface Method (GRSM) can efficiently be used as the optimization method to explore the design space and find out the optimal solution.

Thinking global becomes a philosophy

Expertise, habits, time pressure, missing tools are some of the reasons why many of us may still work in silos. Nevertheless, safe and continuous operation of grid equipment drives the energy market. Therefore, increasing performance and flexibility and averting any downtime that could affect production, remains a necessity. To improve overall performance, the latest Internet of Things technologies, together with advanced simulations, are progressing to interpolate both digital models and the industrial equipment in their “real-world” environment.

Dynamic digital representations, also called “digital twin”, use sensor data to mirror a machine or equipment to understand and optimize performance and up-scale the dynamic models.

This new concept also offers a higher level of flexibility for the designer. Introducing modularity in the models enables product customization and innovation. It also takes into account different department requirements, while containing costs and co-existing with the former and the standard range. In parallel, increasing experience allows engineers to improve the product lifecycle, and optimize their models before any physical operation takes place, thus saving time and reducing total cost of ownership.

Knowledge – Methodology – Tools at the heart of Innovation

Dynamic model management may seem complex. System simulation, often mentioned in the past, is now being adopted as a more central, accessible and useful tool not only for designers, but also for other departments, to connect the physics, the technologies and the people at the heart of the innovation.

Learn more about- Altair's Solutions for IoT: Shaping the Future of Smart Product Design

- Download How to Digitalize Effectively for IoT’ White Paper

- Watch Remy Orban, Mechatronic Designer at Schneider Electric, video interview ‘Schneider Electric uses Flux to Design IoT Actuators‘