Beyond Lightweighting – The Benefits of 3D-Printed Metamaterials

Multi-functional lattice structures utilizing metamaterials have the potential to radically change the future of products that we use in our daily lives and the way in which industries like aerospace and the medical field operate. There are many benefits to 3D-printed metamaterials that go way beyond the lightweighting offered with topology optimization or lattice structures and other common design for additive manufacturing (AM) techniques. Let’s look in more detail at the benefits of this innovative geometric design phenomenon.

Going Further with Metamaterials

One of AM’s key benefits is its ability to reduce the mass of parts, i.e., lightweighting. For many applications, the extra cost of AM compared to traditional methods are offset during the product’s lifetime. For other applications, lightweighting – such as utilizing lattice structures – has little or no effect on the lifetime cost. In these cases, it might be a good idea to consider structures that can provide multiple benefits to the part by utilizing metamaterials. Benefits of 3D-printed metamaterials include structural, thermal, acoustic, and more.

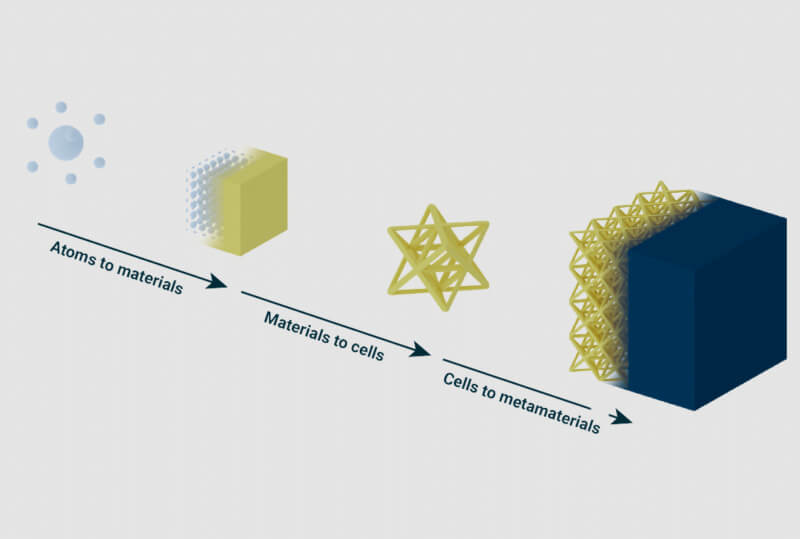

Within a metamaterial, the constituent building blocks are designed and optimized. The final structure is then comprised of these specific building blocks.

From conventional materials to metamaterials. Source: Multiscale Systems

The idea of artificial materials and structures that outperform those that currently exist has, until recently, been available solely in the realm of fiction. However, in the last twenty years, advances in computer-aided design (CAD), simulation, and manufacturing have allowed engineers to make these structures a reality.

Structural Metamaterials

From a structure perspective, metamaterials can be used to create extreme material properties whilst maintaining lightweight structures. Structural elements like closed-cell plate lattices have been shown to be close to the theoretical limit for the stiffness of any material.

This process uses 3D printing on the microscale level called Two-Photon Polymerization Direct Laser Writing (TPP-DLW). Find out more about this in this open-access research paper written by Crook et al.

Auxetic Materials

Another type of structural metamaterial is an auxetic lattice. These structures demonstrate a negative Poisson’s ratio. In materials science, Poisson’s ratio is a measure of the expansion or contraction of a material in the direction perpendicular to the direction of loading. Most naturally occurring solid materials have a positive Poisson’s ratio in the range of 0.2-0.3.

Auxetic materials.

Auxetic metamaterials are interesting to designs as they can be used for a number of applications including energy absorption in body armor or protective sports equipment, drug delivery, stents, or filters.

Thermal Metamaterials

Lattices have been used in thermal applications regularly. These applications can include traditional thermal applications such as heat exchangers and heat sinks. The reason for this is that lattice structures have a high surface area to volume ratio.

Looking to the future, AM can be used for thermal metamaterials that exhibit unusual thermal properties such as constant or negative thermal expansion. Most materials expand when they are heated, however, with these metamaterials, they will either stay the exact same size or even shrink when heated. These structures can be used for many applications including high-precision devices or for space antennas, optical systems, or thermal actuators.

Negative thermal expansion of metamaterials.

Acoustic Metamaterials

Another structure produced by AM is the acoustic metamaterial. Acoustic metamaterials are used to manipulate and control soundwaves within a structure. They are of interest as they have many applications in cloaking, imaging, and noise reduction and enhancement.

Acoustic metamaterial device created by Dr. Fang and his team at the University of Illinois that can be used to render objects in the center invisible to underwater sonar and ultrasonic waves.

Advantages of Lattice Structures

The principal advantage of multi-functional metamaterials is their ability to gain functions beyond what is possible in the natural world. If we can unlock the full advantages that metamaterials can bring, we will be able to design components and products that have properties that far exceed what we have been capable of making up until now.

Additionally, the ability to combine these structures with 3D printing means that you can get the advantages of freeform structures. As with all the metamaterial structures, this means that you can get multi-functionality within a single component. This is particularly interesting for applications where space is restricted. These include aerospace where you may wish to incorporate sound reduction into a standard panel or in motorsport where space is at a minimum.

However, many applications of metamaterials have only been demonstrated in the research world. There are many challenges that must be overcome before we are seeing multi-functional lattice structures applied across a wide range of commercially available products.

Challenges with 3D-Printed Metamaterials

Design

There is a lack of design tools that allow designers to create large scale metamaterial structures. One reason for this is the need to design large parts composed of many small-scale elements. Most typical CAD systems utilize a geometry representation called boundary representation or BRep. The speed of processing this type of geometry is very slow when you reach thousands of faces in the model. However, many companies are now including implicit modelling capabilities within their design tools, and these allow geometry to scale to larger amounts of complexity – making metamaterial component design possible.

Simulation

Simulation of metamaterials is a challenge. Usually, multiphysics simulation tools are expensive and require expertise to use. Furthermore, using small scale unit cells inside a large structure can lead to a data-intensive simulation.

Size

The size of the constituent elements of a material determines the type of frequency that the metamaterial can interact with. The acoustic spectrum lends itself to additively manufactured metamaterials as the wavelength of sound waves from ultrasonic which can be as small as microns to the audible frequency on the scale of meters. These lend themselves well to the current additive manufacturing technologies available.

In contrast, the visible light wavelength exists between 400-700 nanometers. This is generally smaller than the resolution of the majority of additive manufacturing processes, which more specialized AM techniques like TPP-DLW used at these scales.

Conclusion

In the future, multi-functional lattice structures could radically change the products that we use in our daily lives. Although they’re not without their challenges, lattice structures have been demonstrated in both academic and industrial applications. Click here to learn more about Altair’s additive manufacturing capabilities.