Altair Accelerates Simulation-Driven Design in Latest Release of Altair InspireTM

Release includes integration of Altair SimSolidTM for fast, accurate structural analysis of complex assemblies

Troy, Mich. – April 21, 2020 – Altair, (Nasdaq: ALTR) a global technology company providing solutions in product development, high-performance computing (HPC), and data analytics, introduced a new version of Altair InspireTM, the company’s fully-integrated generative design and simulation solution that accelerates the creation, optimization, and study of innovative, structurally efficient parts and assemblies.

The latest release offers an even more powerful and accessible working environment, enabling a simulation-driven design approach that will cut time-to-market, reduce development costs, and optimize product performance.

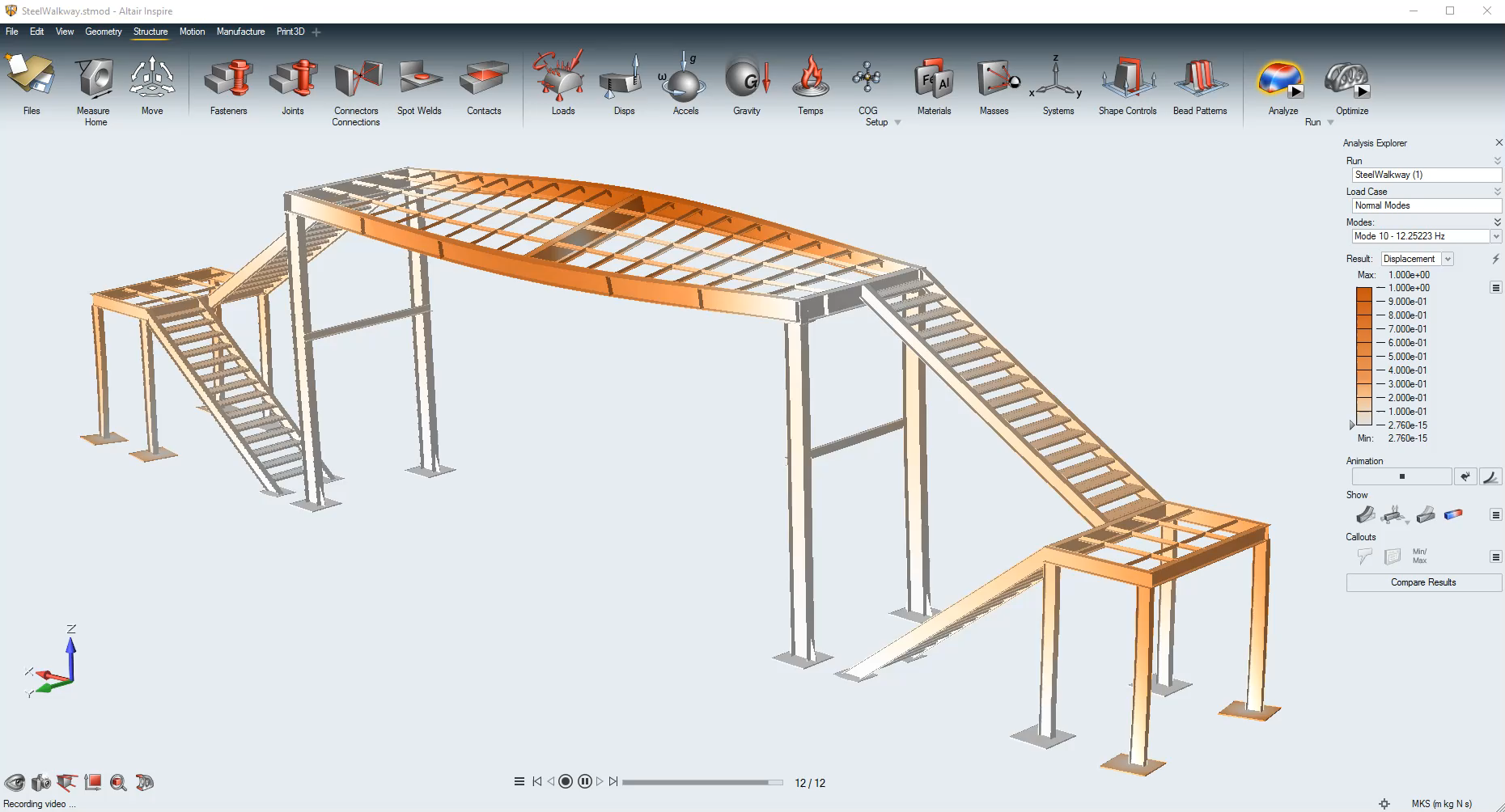

Inspire now integrates Altair SimSolidTM for fast, accurate structural analysis of complex assemblies, as independently validated by NAFEMS. Integration with Inspire’s interactive design engineering environment sees SimSolid join two more trusted industry solvers, empowering users across the engineering and manufacturing sectors:

• Altair OptiStructTM - the market leader and industry standard for structural efficiency and topology optimization for the generative design of practical, viable and manufacturable geometry.

• Altair MotionSolveTM - multi-body systems analysis for dynamic motion simulation, including loads extraction.

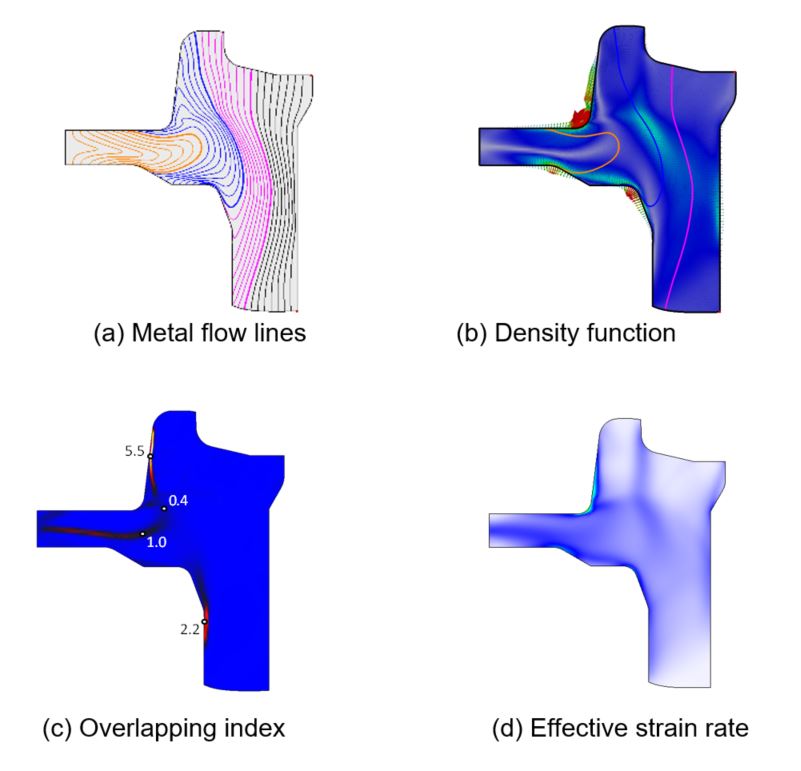

• Inspire Cast, Inspire Form, Inspire Extrude and Inspire Print 3D - manufacturing simulation for product designers and manufacturing simulation specialists.

Developed with engineering leaders, product engineers and simulation specialists in mind, Inspire is intuitive, easy-to-learn in just a few hours and runs on standard laptops and workstations. No additional investment in expensive GPUs is required, and users do not need CAD or other specialist skills. Design changes can be made directly on models without reverting to the original CAD system, and interactive modifications such as geometry edits, dimensional changes, and part replacements can now be re-analysed ‘on the fly’ with SimSolid.

“It’s no longer a question of who is responsible for simulation, but when and where it features in the process,” said James Dagg, Altair chief technology officer – design and simulation solutions. “Instead of employing it purely for validation at the end of the cycle, Inspire enables users to test more alternatives at the earliest opportunity, make better design decisions, and avoid implementing costly modifications at a later stage. The integration of SimSolid further strengthens these capabilities, making it even easier to access remarkable speed, accuracy and flexibility.”

“While offering the potential to significantly expand the usage of analysis to design engineers, the use of Inspire with SimSolid also has high value to simulation and CAE specialists who do not typically use 3D CAD tools,” said Don Tolle, practice director for simulation-driven systems design at CIMdata, a global independent firm providing consulting to maximize an enterprise’s ability to design and deliver innovative products and services through the application of Product Lifecycle Management (PLM). “We believe that the Inspire environment augmented with the SimSolid technology has the potential to be a major positive factor in achieving the PLM industry’s quest for democratization of simulation and the long promised business benefits of simulation-driven design.”

Inspire enables both simulation analysts and designers to perform ‘what-if’ studies faster, easier, and earlier, encouraging collaboration and reducing product time to market. Additional Inspire features include:

• Dynamic Motion – Easily generate dynamic motion of complex mechanisms and use these dynamic loads as loadcases for optimization.

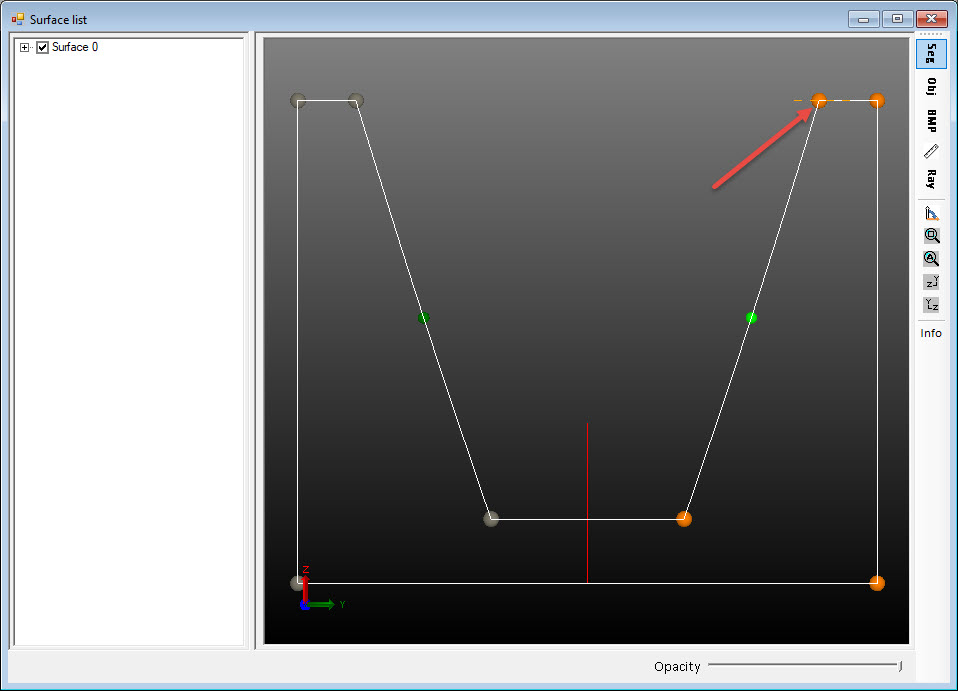

• Topology Optimization – Leverage the world’s leading topology optimization capabilities, including advanced manufacturing constraints, to create manufacturable solutions to real-world problems.

• Design for Additive Manufacturing – Employ overhang shape controls to create more self-supporting structures, then simulate the process to identify and correct potential deformation, delamination, and excessive heating issues before building a part.

• Structural Analysis – Investigate linear static and normal modes analysis on a model and visualize displacement, factor of safety, percent of yield, tension and compression, and more.

• Assembly Configuration – Create multiple assembly configurations which can be used to evaluate various design scenarios and the resulting concepts.

• Manufacturing Simulation – The extended manufacturing versions of Inspire provide high quality simulations of casting, sheet metal forming, 3D printing, extrusion and, soon, injection molding. These solutions provide quick feasibility checks on manufacturability as well as detailed simulations of the manufacturing process.

The latest version of Inspire is now available and SimSolid also remains available to users as a standalone solution. For more information about Inspire, visit: www.altair.com/inspire

The latest release offers an even more powerful and accessible working environment, enabling a simulation-driven design approach that will cut time-to-market, reduce development costs, and optimize product performance.

Inspire now integrates Altair SimSolidTM for fast, accurate structural analysis of complex assemblies, as independently validated by NAFEMS. Integration with Inspire’s interactive design engineering environment sees SimSolid join two more trusted industry solvers, empowering users across the engineering and manufacturing sectors:

• Altair OptiStructTM - the market leader and industry standard for structural efficiency and topology optimization for the generative design of practical, viable and manufacturable geometry.

• Altair MotionSolveTM - multi-body systems analysis for dynamic motion simulation, including loads extraction.

• Inspire Cast, Inspire Form, Inspire Extrude and Inspire Print 3D - manufacturing simulation for product designers and manufacturing simulation specialists.

Developed with engineering leaders, product engineers and simulation specialists in mind, Inspire is intuitive, easy-to-learn in just a few hours and runs on standard laptops and workstations. No additional investment in expensive GPUs is required, and users do not need CAD or other specialist skills. Design changes can be made directly on models without reverting to the original CAD system, and interactive modifications such as geometry edits, dimensional changes, and part replacements can now be re-analysed ‘on the fly’ with SimSolid.

“It’s no longer a question of who is responsible for simulation, but when and where it features in the process,” said James Dagg, Altair chief technology officer – design and simulation solutions. “Instead of employing it purely for validation at the end of the cycle, Inspire enables users to test more alternatives at the earliest opportunity, make better design decisions, and avoid implementing costly modifications at a later stage. The integration of SimSolid further strengthens these capabilities, making it even easier to access remarkable speed, accuracy and flexibility.”

“While offering the potential to significantly expand the usage of analysis to design engineers, the use of Inspire with SimSolid also has high value to simulation and CAE specialists who do not typically use 3D CAD tools,” said Don Tolle, practice director for simulation-driven systems design at CIMdata, a global independent firm providing consulting to maximize an enterprise’s ability to design and deliver innovative products and services through the application of Product Lifecycle Management (PLM). “We believe that the Inspire environment augmented with the SimSolid technology has the potential to be a major positive factor in achieving the PLM industry’s quest for democratization of simulation and the long promised business benefits of simulation-driven design.”

Inspire enables both simulation analysts and designers to perform ‘what-if’ studies faster, easier, and earlier, encouraging collaboration and reducing product time to market. Additional Inspire features include:

• Dynamic Motion – Easily generate dynamic motion of complex mechanisms and use these dynamic loads as loadcases for optimization.

• Topology Optimization – Leverage the world’s leading topology optimization capabilities, including advanced manufacturing constraints, to create manufacturable solutions to real-world problems.

• Design for Additive Manufacturing – Employ overhang shape controls to create more self-supporting structures, then simulate the process to identify and correct potential deformation, delamination, and excessive heating issues before building a part.

• Structural Analysis – Investigate linear static and normal modes analysis on a model and visualize displacement, factor of safety, percent of yield, tension and compression, and more.

• Assembly Configuration – Create multiple assembly configurations which can be used to evaluate various design scenarios and the resulting concepts.

• Manufacturing Simulation – The extended manufacturing versions of Inspire provide high quality simulations of casting, sheet metal forming, 3D printing, extrusion and, soon, injection molding. These solutions provide quick feasibility checks on manufacturability as well as detailed simulations of the manufacturing process.

The latest version of Inspire is now available and SimSolid also remains available to users as a standalone solution. For more information about Inspire, visit: www.altair.com/inspire