Altair Releases Altair EDEM 2020 for Faster Workflows and Faster Results

Recently acquired by Altair, EDEM 2020 includes new tools for easier bulk and granular material simulation

Troy, MI – November 28, 2019 – Altair (Nasdaq: ALTR) a global technology company providing solutions in product development, high-performance

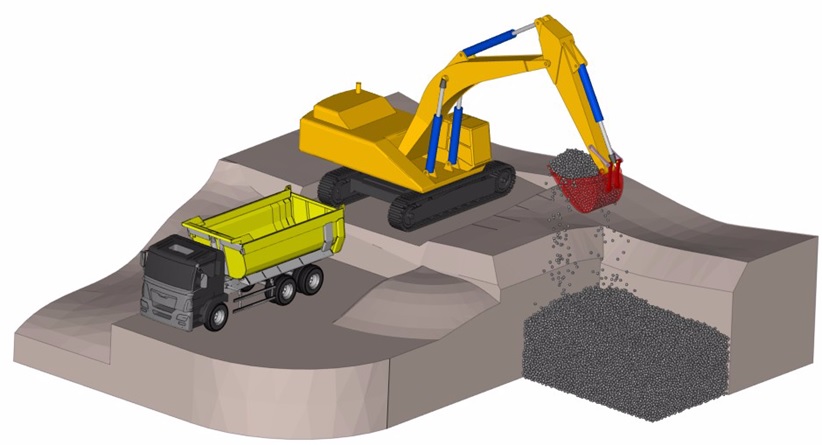

computing and data analytics, has released Altair EDEM 2020, the market leading Discrete Element Method (DEM) software for bulk and granular material simulation.

EDEM is used for virtual testing of equipment that handles or processes bulk materials in the mining, equipment manufacturing and process industries. Companies worldwide use EDEM to optimize equipment design, increase productivity, reduce operational costs, shorten product development cycles and drive product innovation.

EDEM 2020 from DEM Solutions Ltd., recently acquired by Altair, allows for faster workflows, and includes new tools for quicker and easier simulation set-up. The new release also includes new coupling solutions with multi-body dynamics software Altair MotionSolve™ and open source, computational fluid dynamics (CFD) software OpenFOAM.

“Speed has been an important focus for our development work and successive releases have been concentrated on implementing EDEM capabilities for GPU technology, so all users benefit from significant speed up of their simulations,” said Mark Cook, Altair product manager for EDEM. “With EDEM 2020 we are now addressing simulation set-up and introducing advanced capabilities such as Meta-Particles for simulating flexible fibers and Motion Control for advanced geometry movement. Additionally, there are new tools such as sphere fitting which are now standard features in EDEM.”

EDEM 2020 highlights include:

New Sphere Fitting Tool

EDEM can simulate any size and shape of material using the computationally efficient and well validated multi-sphere method. In this method, shape is introduced by overlapping multiple spheres and, by increasing the number of overlapping spheres, it allows for increased shape fidelity. With the new Sphere Fitting tool, users no longer must manually arrange spheres to create the shape they want to represent. The tool automatically builds a multi-sphere particle that closely matches an imported particle shape from a CAD file. Users can control the number of spheres used, as well as restrict the minimum sphere size. This tool means users can get the benefit of efficient multi-sphere simulation without the effort of building the particle shape.

Meta Particles Creation

Many industry applications involve material that is flexible or elongated in nature, such as fibers, agricultural crops and grass. Meta Particles, introduced in the EDEM Creator, enables users to easily create groups of particles to create flexible fibers through the use of a Bonded Model that has been updated to support Meta Particles. It is also fully GPU compliant. This significantly reduces the time and effort needed to set up a simulation for flexible particles and enables all users to create such material in a straight-forward manner.

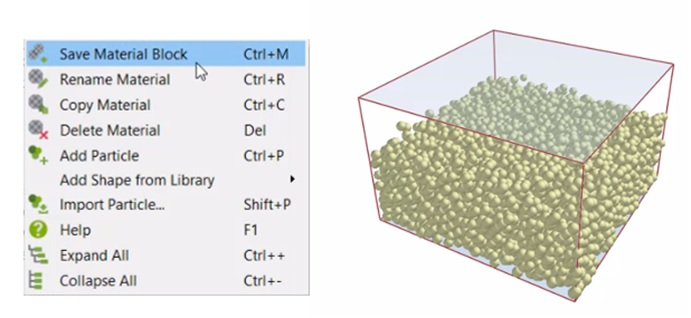

Material Block Dynamic Factory

EDEM has previously introduced a Bed Generation Tool (also known as Material Block) that enables users to generate large beds of material quickly and easily by copying and arranging smaller blocks of material. With EDEM 2020 this capability has been extended to operate as a ‘dynamic factory’ meaning the same block of material can be automatically introduced in a simulation at regular intervals. This works well where batching occurs naturally, such as screw augers, belted conveyors, balers and more. This capability is a powerful way to enable the output of one simulation to be used as input to another simulation without having to re-run it, saving significant amounts of time.

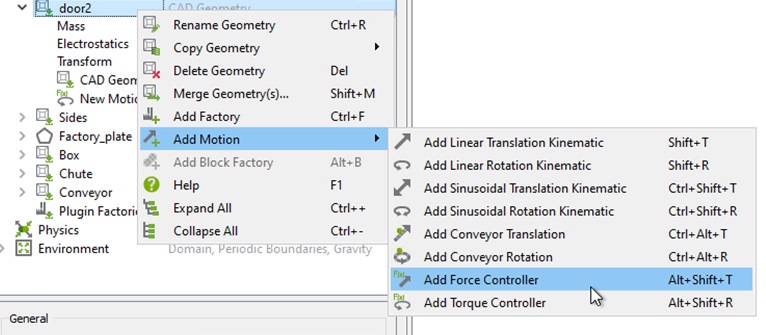

Motion Control

A motion control capability is now available, enabling users to easily introduce motions to geometries that occur due to force or torque being applied. Previously only possible via EDEM’s coupling interface, this capability to add force and torque is now available directly from the EDEM Creator and can be combined with regular kinematics. This creates a powerful environment to easily define a broad range of geometry movements to match real-life equipment movement.

Increased Performance

On the solver side, EDEM 2020 benefits from further speed improvements. Benchmarks have shown great speed-up when using GPU, as opposed to CPU only, with some standard examples showing a speed-up of up to 15 times when using a high-end GPU card versus 12 CPUs. The GPU solver is compatible with API models and the EDEM coupling interface enables all users to benefit from a speed-up regardless of how complex the simulation. Customers can access the GPU benchmarks from the Customer area (login required).

Post-processing – EDEMpy 0.1.2

EDEMpy is a Python library for post-processing and analyzing EDEM simulation data, making it easy for users to extract specific data from a simulation deck and process that data in a customizable and reusable way. A range of enhancements have been made in the latest version including a new binning feature for searching objects inside a box or cylinder bin, new methods for getting sphere position and radii data and improved performance for getting contacts and bonds data.

New EDEM-MotionSolve coupling

Coupling EDEM with multi-body dynamics (MBD) software enable engineers designing heavy equipment to introduce realistic bulk material in their MBD simulations and to get key insight into machine-material interaction. EDEM can now be coupled to Altair MotionSolve in addition to the range of solutions already available with other MBD software.

Enhancements to the EDEM-Fluent coupling

EDEM-Fluent coupling, enabling users to accurately simulate a variety of particle-fluid systems, has been updated and now allows users to transfer chemical-species data. This makes it possible to simulate complex thermal and chemical reactions such as evaporation, and in a subsequent update, it will also enable combustion. This opens the door to a whole new range of applications that rely on processes dependent upon the modelling of these phenomena. For more information about simulating evaporation read this blog post from A. Hobbs at Astec, Inc.

New EDEM-OpenFOAM coupling

Users wanting to perform coupled DEM-CFD simulations now have the choice to couple EDEM with Fluent or the open source software, OpenFOAM. The EDEM-OpenFOAM coupling overcomes one of the common limitations with DEM-CFD coupled simulations, namely that particles must be smaller in volume than the mesh cells they occupy. This allows engineers to simulate a wide range of application types previously not possible. For more information about this coupling read this post.

The full list of enhancements available in EDEM 2020 can be found in the Release Notes here (login required). New to EDEM? Check our eLearning portal and start the free ‘Introduction to EDEM Energy’ video course.

EDEM is used for virtual testing of equipment that handles or processes bulk materials in the mining, equipment manufacturing and process industries. Companies worldwide use EDEM to optimize equipment design, increase productivity, reduce operational costs, shorten product development cycles and drive product innovation.

EDEM 2020 from DEM Solutions Ltd., recently acquired by Altair, allows for faster workflows, and includes new tools for quicker and easier simulation set-up. The new release also includes new coupling solutions with multi-body dynamics software Altair MotionSolve™ and open source, computational fluid dynamics (CFD) software OpenFOAM.

“Speed has been an important focus for our development work and successive releases have been concentrated on implementing EDEM capabilities for GPU technology, so all users benefit from significant speed up of their simulations,” said Mark Cook, Altair product manager for EDEM. “With EDEM 2020 we are now addressing simulation set-up and introducing advanced capabilities such as Meta-Particles for simulating flexible fibers and Motion Control for advanced geometry movement. Additionally, there are new tools such as sphere fitting which are now standard features in EDEM.”

EDEM 2020 highlights include:

New Sphere Fitting Tool

EDEM can simulate any size and shape of material using the computationally efficient and well validated multi-sphere method. In this method, shape is introduced by overlapping multiple spheres and, by increasing the number of overlapping spheres, it allows for increased shape fidelity. With the new Sphere Fitting tool, users no longer must manually arrange spheres to create the shape they want to represent. The tool automatically builds a multi-sphere particle that closely matches an imported particle shape from a CAD file. Users can control the number of spheres used, as well as restrict the minimum sphere size. This tool means users can get the benefit of efficient multi-sphere simulation without the effort of building the particle shape.

Meta Particles Creation

Many industry applications involve material that is flexible or elongated in nature, such as fibers, agricultural crops and grass. Meta Particles, introduced in the EDEM Creator, enables users to easily create groups of particles to create flexible fibers through the use of a Bonded Model that has been updated to support Meta Particles. It is also fully GPU compliant. This significantly reduces the time and effort needed to set up a simulation for flexible particles and enables all users to create such material in a straight-forward manner.

Material Block Dynamic Factory

EDEM has previously introduced a Bed Generation Tool (also known as Material Block) that enables users to generate large beds of material quickly and easily by copying and arranging smaller blocks of material. With EDEM 2020 this capability has been extended to operate as a ‘dynamic factory’ meaning the same block of material can be automatically introduced in a simulation at regular intervals. This works well where batching occurs naturally, such as screw augers, belted conveyors, balers and more. This capability is a powerful way to enable the output of one simulation to be used as input to another simulation without having to re-run it, saving significant amounts of time.

Motion Control

A motion control capability is now available, enabling users to easily introduce motions to geometries that occur due to force or torque being applied. Previously only possible via EDEM’s coupling interface, this capability to add force and torque is now available directly from the EDEM Creator and can be combined with regular kinematics. This creates a powerful environment to easily define a broad range of geometry movements to match real-life equipment movement.

Increased Performance

On the solver side, EDEM 2020 benefits from further speed improvements. Benchmarks have shown great speed-up when using GPU, as opposed to CPU only, with some standard examples showing a speed-up of up to 15 times when using a high-end GPU card versus 12 CPUs. The GPU solver is compatible with API models and the EDEM coupling interface enables all users to benefit from a speed-up regardless of how complex the simulation. Customers can access the GPU benchmarks from the Customer area (login required).

Post-processing – EDEMpy 0.1.2

EDEMpy is a Python library for post-processing and analyzing EDEM simulation data, making it easy for users to extract specific data from a simulation deck and process that data in a customizable and reusable way. A range of enhancements have been made in the latest version including a new binning feature for searching objects inside a box or cylinder bin, new methods for getting sphere position and radii data and improved performance for getting contacts and bonds data.

New EDEM-MotionSolve coupling

Coupling EDEM with multi-body dynamics (MBD) software enable engineers designing heavy equipment to introduce realistic bulk material in their MBD simulations and to get key insight into machine-material interaction. EDEM can now be coupled to Altair MotionSolve in addition to the range of solutions already available with other MBD software.

Enhancements to the EDEM-Fluent coupling

EDEM-Fluent coupling, enabling users to accurately simulate a variety of particle-fluid systems, has been updated and now allows users to transfer chemical-species data. This makes it possible to simulate complex thermal and chemical reactions such as evaporation, and in a subsequent update, it will also enable combustion. This opens the door to a whole new range of applications that rely on processes dependent upon the modelling of these phenomena. For more information about simulating evaporation read this blog post from A. Hobbs at Astec, Inc.

New EDEM-OpenFOAM coupling

Users wanting to perform coupled DEM-CFD simulations now have the choice to couple EDEM with Fluent or the open source software, OpenFOAM. The EDEM-OpenFOAM coupling overcomes one of the common limitations with DEM-CFD coupled simulations, namely that particles must be smaller in volume than the mesh cells they occupy. This allows engineers to simulate a wide range of application types previously not possible. For more information about this coupling read this post.

The full list of enhancements available in EDEM 2020 can be found in the Release Notes here (login required). New to EDEM? Check our eLearning portal and start the free ‘Introduction to EDEM Energy’ video course.