Altair and APWORKS Jointly Present Innovative Design Processes, Materials and Software Tools for Additive Manufacturing at formnext in Frankfurt

Optimizing a front-end structure with functional integration and simulation, the project 3i-PRINT provides impressive insight into the potential of industrial 3D printing for vehicle body design

Altair and APWORKS will present jointly at this year’s formnext 2017 in Frankfurt, November 14 – 17th, exhibiting new design processes, materials, and software tools for industrial 3D printing.

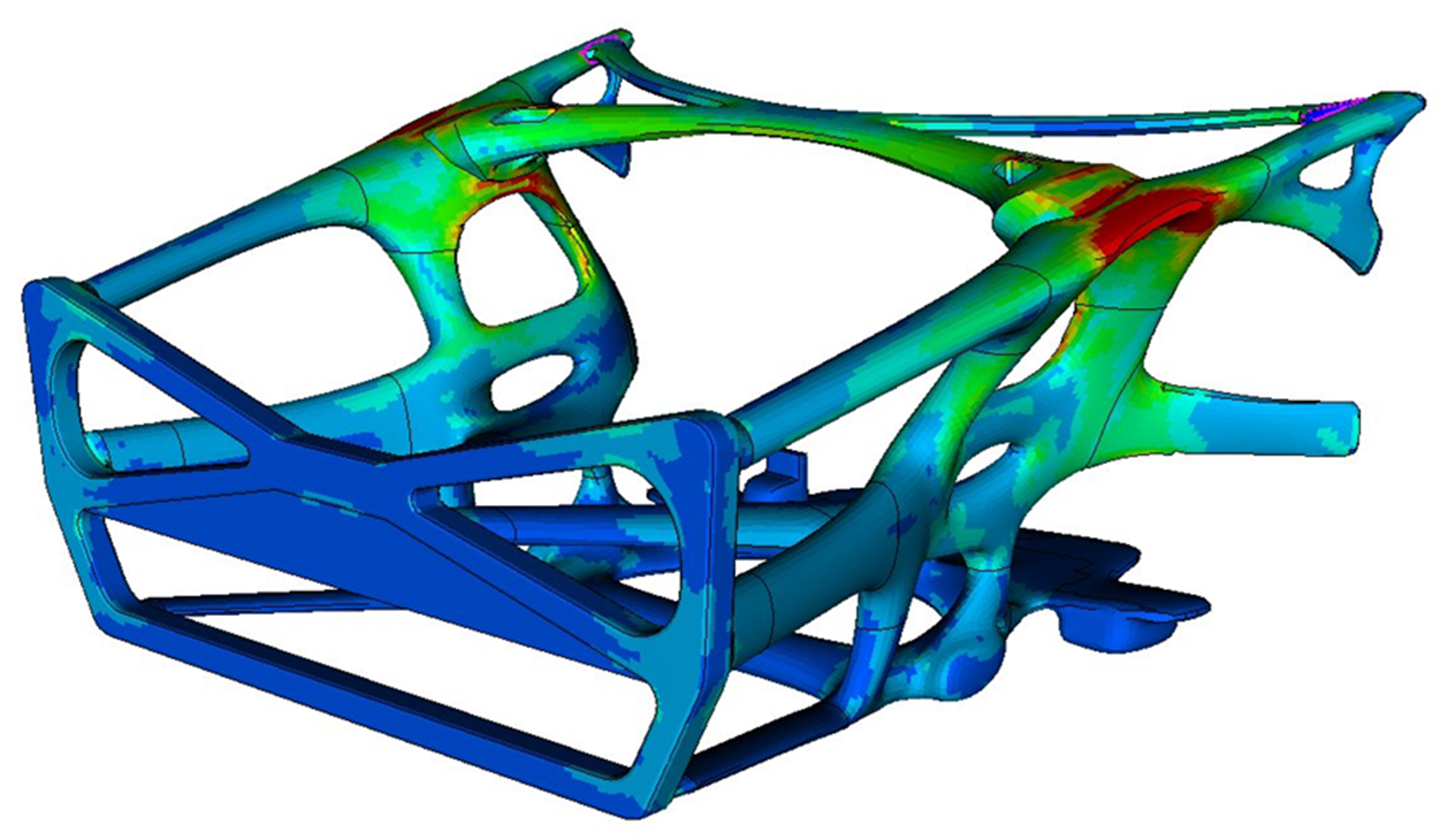

3i-PRINT, a joint project by Altair, APWORKS, csi entwicklungstechnik, EOS GmbH, GERG, and Heraeus, impressively demonstrates the possibilities of vehicle body design, combining state-of-the-art simulation software, innovative materials, and 3D printing as a modern manufacturing technology. Being a special highlight in industrial 3D printing, attendees can look forward to seeing the additively manufactured front-end structure of a VW Caddy Youngtimer at the Altair and APWORKS booth. Optimized with regard to structural and crash performance, thanks to simulation-driven design and the creative employment of the design freedom offered by 3D printing, the front-end structure is a true 'lightweight' offering various functionally integrated components such as for passive and active cooling of the electric powertrain.

Engineers from csi entwicklungstechnik simulated, designed and optimized the front-end structure with Altair's HyperWorks® suite. After that, APWORKS took care of the manufacturing of the front-end structure on an EOS M 400 system using Scalmalloy®, a new material developed by APWORKS and supplied by Heraeus. Specialists from GERG created the final frame and connected the 3D printed components.

At the booth and during the workshop “The Making of 3i-PRINT" on November 15 at 10:00 am, in room 'Aspekt', hall 3, level C, formnext guests will have the opportunity to learn more about the project.

Further highlights at the booth:

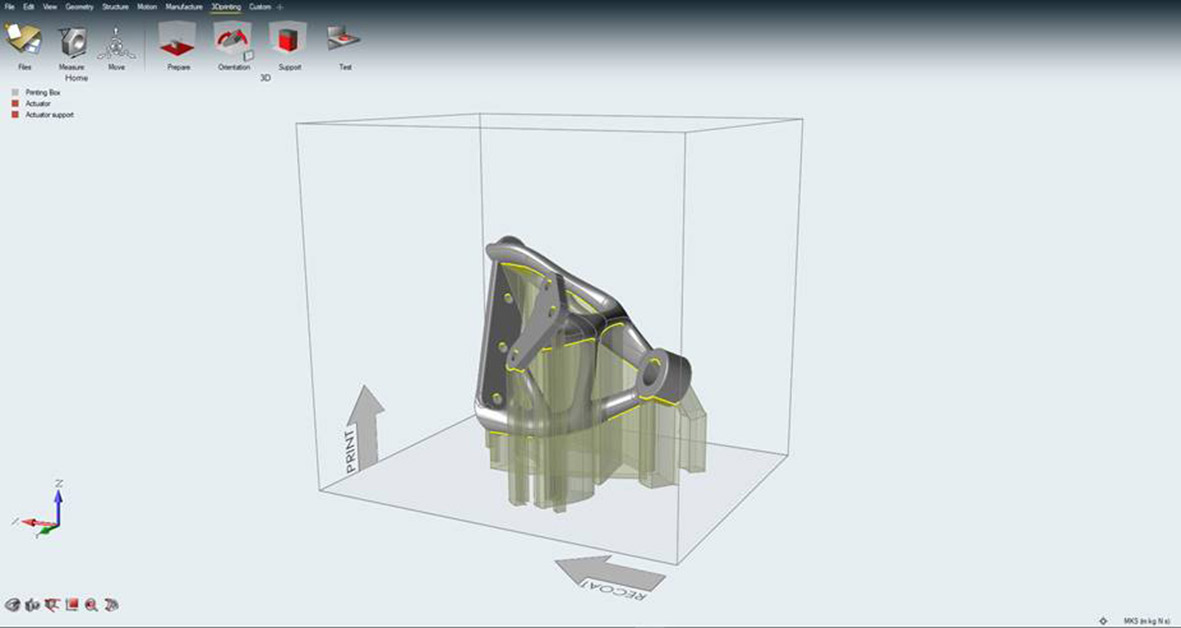

“We are looking forward to present our new software solutions and development methods to the formnext audience,“ says Mirko Bromberger, head of Marketing and Additive Manufacturing strategies at Altair Engineering. “We will show a prototype of the new solidThinking Inspire release that now enables topology optimization for hybrid solid/lattice structures. As such, areas with different densities and orthotropic properties can be realized, and the potential of additive manufacturing fully exploited. With the AM specific boundary conditions for topology optimization, easy geometry I/O, component orientation in the printer, generation of support structures, and many other features, we contribute to closing the gap in the digital process chain."

"Last year at the formnext we presented our Light Rider project, the worldwide first 3D-printed prototype of a motorcycle, which will again be exhibited at our booth," explains Sven Lauxmann, Head of Marketing and Sales at APWORKS. "This year we are looking forward to bring our concept “ReThink” to visitors’ attention. ReThink does not only mean to exploit the manifold design possibilities of 3D printing and to use high performance material such as Scalmalloy®, it also means to qualify 3D printing for serial production.”

Visit Altair and APWORKS at the formnext in hall 3.1 booth E69/F70, and the workshop: "The Making-of 3i-PRINT" to learn more about the making of the 3i-PRINT project on November 15 at 10:00 am in room Aspekt, hall 3, level C. Learn more at: https://web2.altairhyperworks.com/workshop-experience-3iprint.

3i-PRINT, a joint project by Altair, APWORKS, csi entwicklungstechnik, EOS GmbH, GERG, and Heraeus, impressively demonstrates the possibilities of vehicle body design, combining state-of-the-art simulation software, innovative materials, and 3D printing as a modern manufacturing technology. Being a special highlight in industrial 3D printing, attendees can look forward to seeing the additively manufactured front-end structure of a VW Caddy Youngtimer at the Altair and APWORKS booth. Optimized with regard to structural and crash performance, thanks to simulation-driven design and the creative employment of the design freedom offered by 3D printing, the front-end structure is a true 'lightweight' offering various functionally integrated components such as for passive and active cooling of the electric powertrain.

Engineers from csi entwicklungstechnik simulated, designed and optimized the front-end structure with Altair's HyperWorks® suite. After that, APWORKS took care of the manufacturing of the front-end structure on an EOS M 400 system using Scalmalloy®, a new material developed by APWORKS and supplied by Heraeus. Specialists from GERG created the final frame and connected the 3D printed components.

At the booth and during the workshop “The Making of 3i-PRINT" on November 15 at 10:00 am, in room 'Aspekt', hall 3, level C, formnext guests will have the opportunity to learn more about the project.

Further highlights at the booth:

- Closing the digital process chain for product development with regard to additive manufacturing is the main focus of Altair’s software additions. Altair will provide an exclusive world-preview of new features added to solidThinking Inspire®. The software now includes manufacturing constraints for 3D printing, such as support structures, the generation and visualization of hybrid lattice structures, component orientation in the printer, and much more, when conducting a topology optimization.

- In addition, Inspire Unlimited – Altair's platform for product development in the cloud, soon to be available in Europe - will be presented. formnext visitors can experience the platform on-site at the booth and learn more about the capabilities and potential of this browser based development environment.

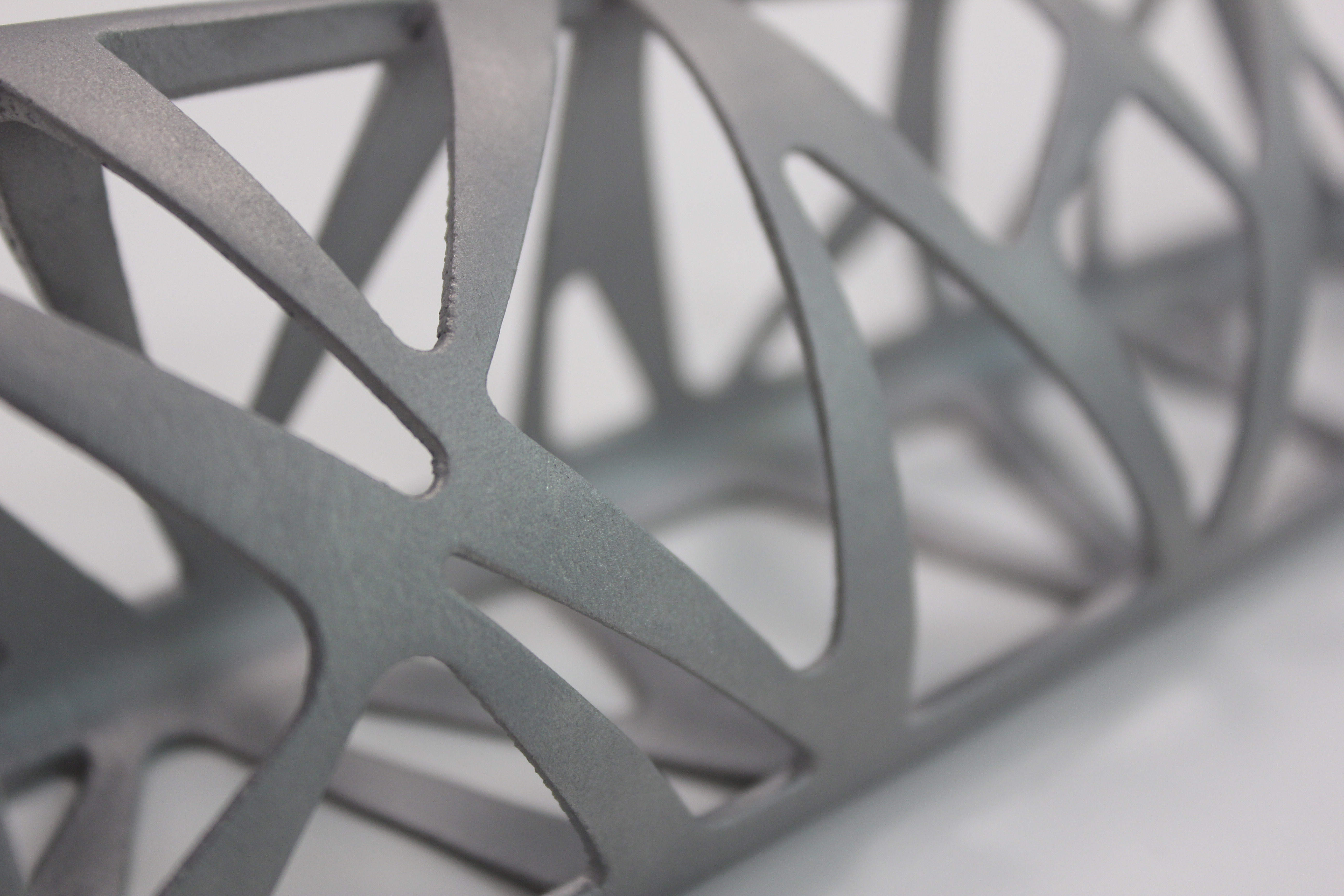

- Visiting APWORKS, formnext guests will experience Scalmalloy®, APWORKS’ patented aluminum alloy. As the first material worldwide specifically developed for 3D printing, Scalmalloy® combines the ductility of titanium with the weight of aluminum. When combined with the design freedom offered by additive manufacturing, it enables production of some of the most efficient components.

- Furthermore, at APWORKS, guests can learn more about the company‘s understanding of "design for additive manufacturing", find out about APWORKS' concepts for a qualified serial production of components as well as the company’s processes and service offerings for additive manufacturing.

“We are looking forward to present our new software solutions and development methods to the formnext audience,“ says Mirko Bromberger, head of Marketing and Additive Manufacturing strategies at Altair Engineering. “We will show a prototype of the new solidThinking Inspire release that now enables topology optimization for hybrid solid/lattice structures. As such, areas with different densities and orthotropic properties can be realized, and the potential of additive manufacturing fully exploited. With the AM specific boundary conditions for topology optimization, easy geometry I/O, component orientation in the printer, generation of support structures, and many other features, we contribute to closing the gap in the digital process chain."

"Last year at the formnext we presented our Light Rider project, the worldwide first 3D-printed prototype of a motorcycle, which will again be exhibited at our booth," explains Sven Lauxmann, Head of Marketing and Sales at APWORKS. "This year we are looking forward to bring our concept “ReThink” to visitors’ attention. ReThink does not only mean to exploit the manifold design possibilities of 3D printing and to use high performance material such as Scalmalloy®, it also means to qualify 3D printing for serial production.”

Visit Altair and APWORKS at the formnext in hall 3.1 booth E69/F70, and the workshop: "The Making-of 3i-PRINT" to learn more about the making of the 3i-PRINT project on November 15 at 10:00 am in room Aspekt, hall 3, level C. Learn more at: https://web2.altairhyperworks.com/workshop-experience-3iprint.