Altair to Present “Simulation-Driven Design for Advanced Manufacturing” at Formnext in Frankfurt

Altair, along with co-exhibitors from its reseller community, will present solutions enabling simulation-driven design processes, driving modern manufacturing from capability to capacity.

Böblingen, Germany - October 01, 2019 – Altair (Nasdaq: ALTR) a global technology company providing solutions in product development, high-performance computing and data intelligence, announced it will present its methods and solutions for modern manufacturing at Formnext2019 in Frankfurt, November 19-22. With the tools and methods provided by Altair, technology companies can reach their full design and manufacturing potential to create advanced products and services.

Formnext is the international exhibition and conference on additive manufacturing and the next generation of intelligent industrial production. Aligning with Formnext's motto of "Turning your Ideas into Reality" Altair will present development and design processes and solutions, driving design and modern manufacturing processes from capability to capacity.

Jointly with co-exhibitors from the Altair European reseller community – among them M&H, Elmec, and a delegation of Eastern European resellers – Altair will showcase practical use cases, including mobility, medical, tooling and other industry applications. Highlights will include the Andiamo use case, featuring 3D-printed orthoses for children; the biggest 3D-printed aerospace application to-date by South African research initiative Aeroswift; simulation-driven designed and pneumatically actuated robot with printed lightweight structures based on the EU funded research project DIMAP (GA No. 685937) and PhD project of Gabriel Dämmer, and many more.

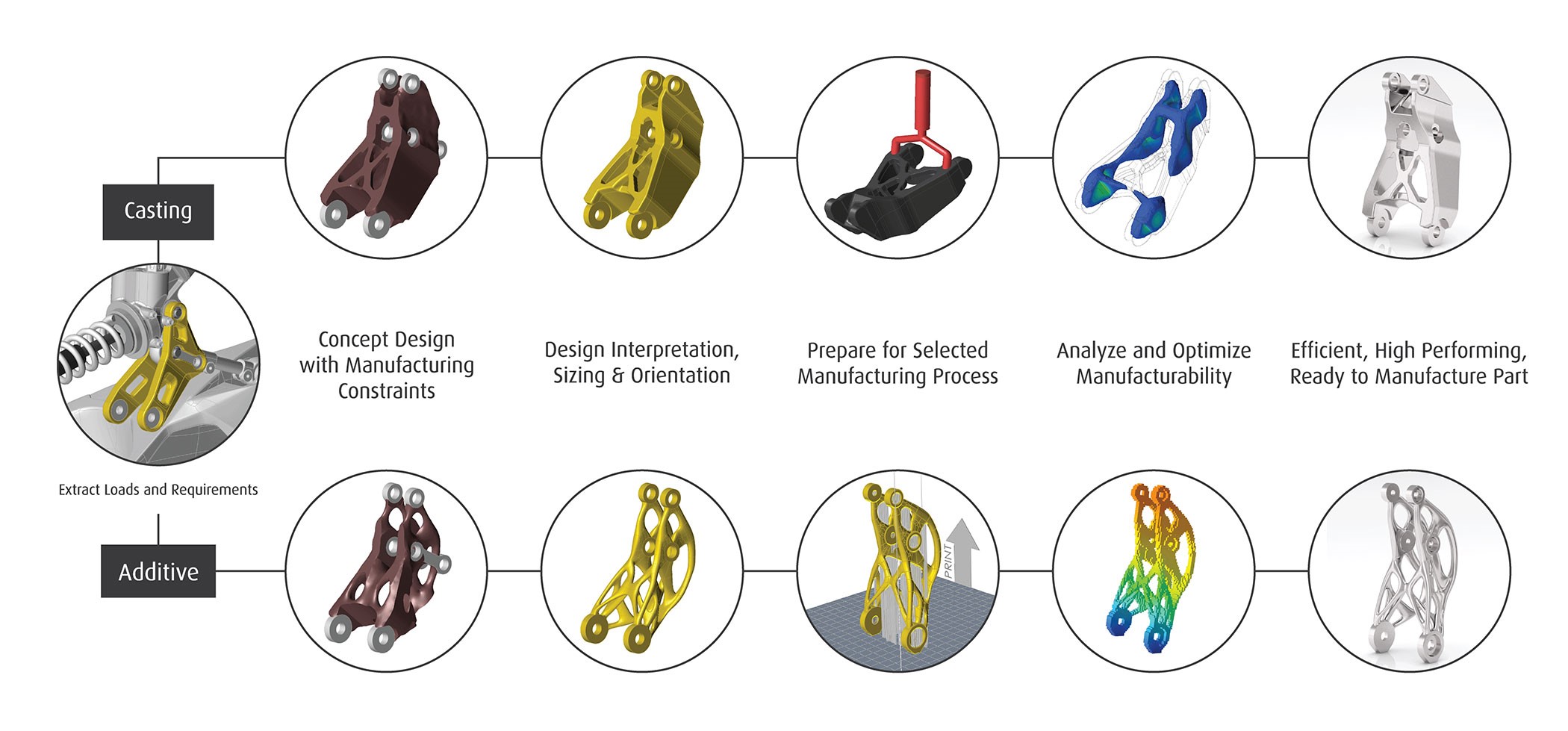

“We are showcasing breakthrough, real-life use cases that demonstrate the power our development methods, simulation-driven design approach and tools have," said Dr. Pietro Cervellera, senior vice president EMEA operations, Altair. "These outstanding innovations illustrate the entire design process beginning with the identification of requirements that feed generative design, considering manufacturing design rules, the setup of the chosen manufacturing process and a feasibility check. The new automatic geometry creation and the manufacturing process simulation capabilities are unparalleled, and the workflow ensures product developers will be able to confidently generate industrial-relevant results.”

Exploring these use cases, Formnext visitors can experience how Altair’s workflow serves manufacturing realities, all while gaining a competitive edge in the design process. All use cases highlight the journey of advanced manufacturing (from design to production) answering fundamental questions such as:

Formnext is the international exhibition and conference on additive manufacturing and the next generation of intelligent industrial production. Aligning with Formnext's motto of "Turning your Ideas into Reality" Altair will present development and design processes and solutions, driving design and modern manufacturing processes from capability to capacity.

Jointly with co-exhibitors from the Altair European reseller community – among them M&H, Elmec, and a delegation of Eastern European resellers – Altair will showcase practical use cases, including mobility, medical, tooling and other industry applications. Highlights will include the Andiamo use case, featuring 3D-printed orthoses for children; the biggest 3D-printed aerospace application to-date by South African research initiative Aeroswift; simulation-driven designed and pneumatically actuated robot with printed lightweight structures based on the EU funded research project DIMAP (GA No. 685937) and PhD project of Gabriel Dämmer, and many more.

“We are showcasing breakthrough, real-life use cases that demonstrate the power our development methods, simulation-driven design approach and tools have," said Dr. Pietro Cervellera, senior vice president EMEA operations, Altair. "These outstanding innovations illustrate the entire design process beginning with the identification of requirements that feed generative design, considering manufacturing design rules, the setup of the chosen manufacturing process and a feasibility check. The new automatic geometry creation and the manufacturing process simulation capabilities are unparalleled, and the workflow ensures product developers will be able to confidently generate industrial-relevant results.”

Exploring these use cases, Formnext visitors can experience how Altair’s workflow serves manufacturing realities, all while gaining a competitive edge in the design process. All use cases highlight the journey of advanced manufacturing (from design to production) answering fundamental questions such as:

- Which manufacturing method is the best for any given design?

- How do we create the best possible shape to benefit from the design freedom of 3D printing?

- How do we capture organic shapes within the user’s CAD system?

- How do we ensure part performance and manufacturability, considering manufacturing design rules?