GE’s Flow Simulator Software Now Available Exclusively from Altair

GE’s patented engine system modeling technology is now available for use by Altair customers

Altair (Nasdaq: ALTR) is pleased to add GE’s Flow Simulator software to the Altair Partner Alliance (APA) and offer direct licenses to Altair customers. Flow Simulator is an integrated flow, heat transfer, and combustion design software that enables mixed fidelity simulations to optimize machine and systems design.

“GE’s Flow Simulator will benefit our customers by providing thermal fluid system mixed fidelity simulation capabilities relevant to multiple industries. It expands our strong multiphysics system modeling portfolio, and we are very positive about working with GE to carry their great development work forward to a broader set of customers and applications,” said Brett Chouinard, Altair’s President and COO.

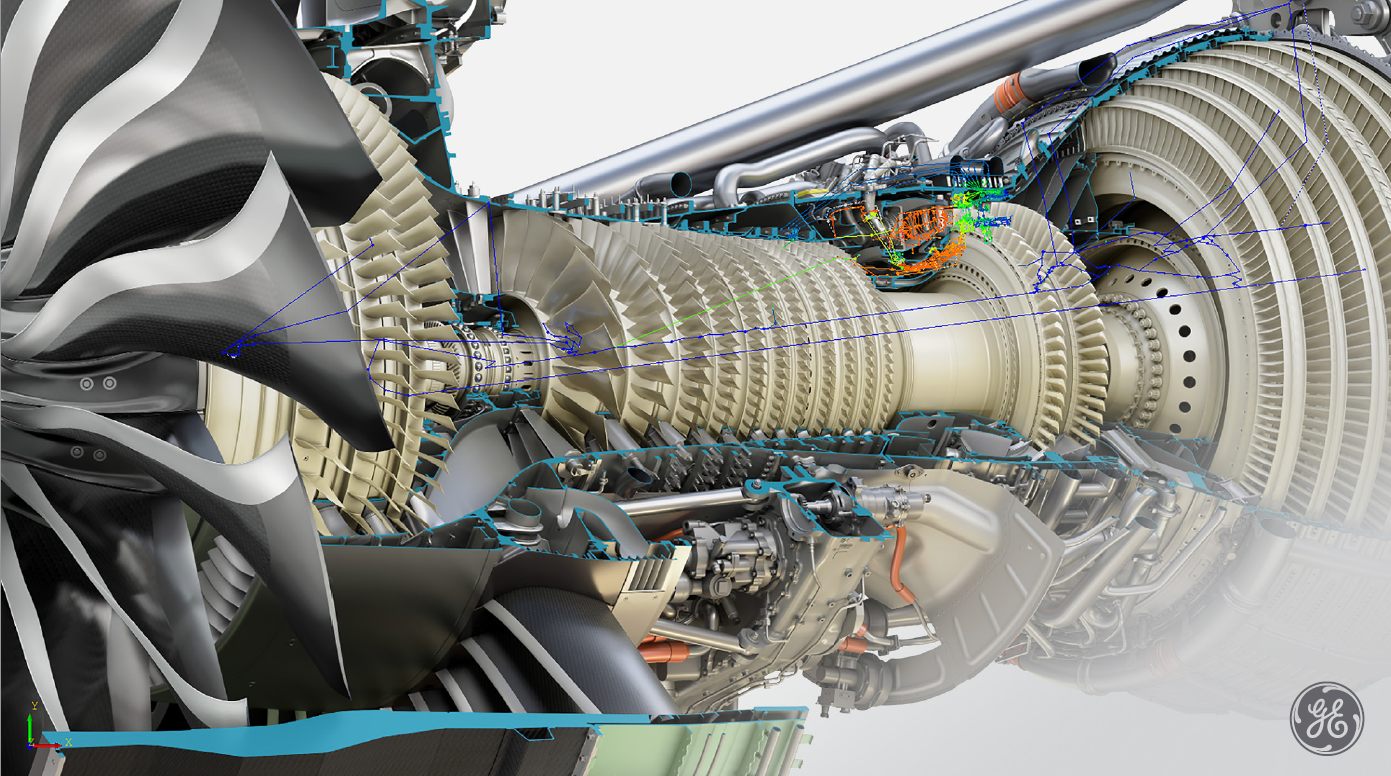

This fluid system design tool provides interdisciplinary modeling and optimization capabilities within a single platform for machine design with respect to fluid dynamics, thermal, and combustion within a 3D design environment. This tool allows users to import actual hardware and utilization of 3D CAD point-cloud to automatically create the computational model overlaid on the machine hardware. An extended library of preconfigured elements and components is available to simulate a wide-range of physical phenomena including; compressible and incompressible fluid flow; buoyancy-driven flow; rotating cavity system flow; conduction, convection and radiation heat transfer; and combustion equilibrium-chemistry and species transport.

Flow Simulator can be used in many industries including aerospace, power generation, oil & gas power conversion, transportation, additive manufacturing, automotive, and others. The capabilities of GE’s Flow Simulator cover a wide range of applications within these industries including; turbomachinery rotating cavity systems, secondary flow and engine sealing, combustor cooling, fuel and lube systems, and power plan piping networks.

“Every 2 seconds, a GE, CFM or Engine Alliance powered engine takes off or lands somewhere around the world. A key part of this success is our ability to perform advanced simulations of how the aircraft and our engines operate,” said Tim Stone, Chief Consulting Engineer, Component Design at GE Aviation. “The tool we use for advanced fluid simulations is Flow Simulator. Due to its modern graphical user interface, advanced simulation capabilities, accuracy, speed and robustness, Flow Simulator is our day-to-day work horse to design and simulate engine sealing systems, structures cooling, rotating cavity systems, combustor cooling, and thermal management. The accuracy and robustness of our Flow Simluator software has played a major role in the success of our engines.”

An introductory webinar for GE’s Flow Simulator software will be held on July 12 at 10 a.m. EST. For more information about the software, please visit the product page for Flow Simulator. APA-enabled HyperWorks customers can download Flow Simulator software here.

“GE’s Flow Simulator will benefit our customers by providing thermal fluid system mixed fidelity simulation capabilities relevant to multiple industries. It expands our strong multiphysics system modeling portfolio, and we are very positive about working with GE to carry their great development work forward to a broader set of customers and applications,” said Brett Chouinard, Altair’s President and COO.

This fluid system design tool provides interdisciplinary modeling and optimization capabilities within a single platform for machine design with respect to fluid dynamics, thermal, and combustion within a 3D design environment. This tool allows users to import actual hardware and utilization of 3D CAD point-cloud to automatically create the computational model overlaid on the machine hardware. An extended library of preconfigured elements and components is available to simulate a wide-range of physical phenomena including; compressible and incompressible fluid flow; buoyancy-driven flow; rotating cavity system flow; conduction, convection and radiation heat transfer; and combustion equilibrium-chemistry and species transport.

Flow Simulator can be used in many industries including aerospace, power generation, oil & gas power conversion, transportation, additive manufacturing, automotive, and others. The capabilities of GE’s Flow Simulator cover a wide range of applications within these industries including; turbomachinery rotating cavity systems, secondary flow and engine sealing, combustor cooling, fuel and lube systems, and power plan piping networks.

“Every 2 seconds, a GE, CFM or Engine Alliance powered engine takes off or lands somewhere around the world. A key part of this success is our ability to perform advanced simulations of how the aircraft and our engines operate,” said Tim Stone, Chief Consulting Engineer, Component Design at GE Aviation. “The tool we use for advanced fluid simulations is Flow Simulator. Due to its modern graphical user interface, advanced simulation capabilities, accuracy, speed and robustness, Flow Simulator is our day-to-day work horse to design and simulate engine sealing systems, structures cooling, rotating cavity systems, combustor cooling, and thermal management. The accuracy and robustness of our Flow Simluator software has played a major role in the success of our engines.”

An introductory webinar for GE’s Flow Simulator software will be held on July 12 at 10 a.m. EST. For more information about the software, please visit the product page for Flow Simulator. APA-enabled HyperWorks customers can download Flow Simulator software here.