Incorporating Variability in Simulation Models with RAMDO via the Altair Partner Alliance

RAMDO by RAMDO Solutions is now available for use by APA enabled HyperWorks® customers

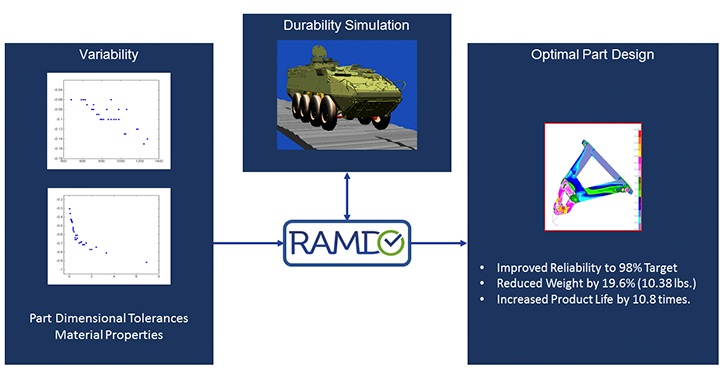

TROY, Mich. – February 2, 2018 – Altair Engineering Inc. (Nasdaq: ALTR) is pleased to announce the addition of RAMDO, software developed by RAMDO Solutions, to the Altair Partner Alliance (APA). RAMDO is an Uncertainty Quantification (UQ), reliability analysis, and Reliability-based Design Optimization (RBDO) software platform. As a complementary CAE software when used in conjunction with a design simulation package, RAMDO provides a more reliable product design. It allows the designer to take into account the variability of design inputs (materials, loads, operating conditions, etc.) and create an optimized solution. RAMDO uniquely performs this analysis with efficient use of computer resources, a user-friendly interface, and at a cost-effective license subscription.

“We are excited to be joining the Altair Partner Alliance,” said Nicholas Gaul, COO and Lead Developer at RAMDO Solutions. “RAMDO can be a great tool for HyperWorks users to explore design reliability improvements by the formal inclusion of variability (materials, loads, manufacturing, operational conditions, etc.) into simulations. Our software increases the reliability and robustness of designs at reduced total product lifecycle costs, thus ultimately creating better products and happier end customers.”

Companies using design simulation software can benefit from adding RAMDO to their workflows. In the aerospace industry, RAMDO can be of particular interest in the design of wings, engines, and interiors by taking into account the variability of materials, aerodynamic loads, electrical resistance, manufacturing, and operating conditions. In the architecture, engineering, & construction industry, RAMDO can help structural designers take into account variability of structural & wind loads, material properties for steel, concrete, soil, and fluid flows for thermal distribution and solar loading. The primary goal of this product is twofold. First, it provides users with a tool to help them understand how variability affects their application. Second, it guides designers into improving the reliability of their design for products and systems. An intermediate benefit of this tool is also a reduction of computational times for UQ, reliability analysis, and RBDO. The result for end consumers is a product that usually includes reduced weight, lower costs, less frequent maintenance, as well as improved safety.

“Structural optimization is used as part of many standard design processes to create better-performing products at lower costs. However, it is important to note that an optimized design could be at the edge of feasibility when considering potential variations due to manufacturing, operational environment, etc.,” explains Fatma Kocer, Altair’s VP of Business Development - Design Exploration. “When this risk is significant, a safety factors approach can be employed, but this approach can lead to overdesigned products. We are happy to have RAMDO in the APA program with solutions for complex problems of reliability and robustness-based design optimization.”

An introductory webinar for RAMDO will be held on February 15 at 10 a.m. EST. For more information about the software, please visit the product page for RAMDO.

“We are excited to be joining the Altair Partner Alliance,” said Nicholas Gaul, COO and Lead Developer at RAMDO Solutions. “RAMDO can be a great tool for HyperWorks users to explore design reliability improvements by the formal inclusion of variability (materials, loads, manufacturing, operational conditions, etc.) into simulations. Our software increases the reliability and robustness of designs at reduced total product lifecycle costs, thus ultimately creating better products and happier end customers.”

Companies using design simulation software can benefit from adding RAMDO to their workflows. In the aerospace industry, RAMDO can be of particular interest in the design of wings, engines, and interiors by taking into account the variability of materials, aerodynamic loads, electrical resistance, manufacturing, and operating conditions. In the architecture, engineering, & construction industry, RAMDO can help structural designers take into account variability of structural & wind loads, material properties for steel, concrete, soil, and fluid flows for thermal distribution and solar loading. The primary goal of this product is twofold. First, it provides users with a tool to help them understand how variability affects their application. Second, it guides designers into improving the reliability of their design for products and systems. An intermediate benefit of this tool is also a reduction of computational times for UQ, reliability analysis, and RBDO. The result for end consumers is a product that usually includes reduced weight, lower costs, less frequent maintenance, as well as improved safety.

“Structural optimization is used as part of many standard design processes to create better-performing products at lower costs. However, it is important to note that an optimized design could be at the edge of feasibility when considering potential variations due to manufacturing, operational environment, etc.,” explains Fatma Kocer, Altair’s VP of Business Development - Design Exploration. “When this risk is significant, a safety factors approach can be employed, but this approach can lead to overdesigned products. We are happy to have RAMDO in the APA program with solutions for complex problems of reliability and robustness-based design optimization.”

An introductory webinar for RAMDO will be held on February 15 at 10 a.m. EST. For more information about the software, please visit the product page for RAMDO.