RMIT and Altair Collaborate to Prepare Future Engineers in Simulation-driven Design

Altair HyperWorks and solidThinking CAE suites now available at RMIT University

Altair (Nasdaq:ALTR) and RMIT University, Australia announce wider access to students and staff for the Altair HyperWorks™ and solidThinking suites.

RMIT students and staff in the College of Science, Engineering and Health will get unlimited access to high-end simulation software used by engineers across the world under a first of its kind agreement in Australia with global company Altair Engineering.

The technology is used by companies including Boeing, BAE, Telstra and GM Holden to reduce the weight of aeroplane and automotive structures, make Japan’s high-speed bullet trains safer, develop ultra-light bikes and drones, create wireless sensors that detect damage to planes from lighting strikes and for simulating bio-electromagnetic effects.

It’s the first time American-based Altair has worked with an Australian University to enable access to its engineering software programs for teaching and non-commercial research use and the agreement is another great example of RMIT’s commitment to delivering industry-ready graduates.

The agreement is the brainchild of Joel Kennedy, an RMIT alumni and Project Engineer at Altair.

“RMIT had previous, limited access to the software. Students are currently using the simulation software as part of RMIT Combustion and Electric Racing, which competes in the Formula SAE competition, and the RMIT unmanned aircraft systems research team, which has seen staff and students showcase high-tech autonomous drones in overseas competition,” said Kennedy.

“I used some of the design software during my studies but wasn’t taught HyperWorks. Now working with it, I can see the level of impact it has in industry and it will only continue to grow. This campus-wide agreement means students across science, engineering and health courses can access world-class engineering tools,” he said.

Associate Dean of Aerospace Engineering and Aviation Professor Pier Marzocca welcomes the agreement.

“From few users to many, it is fantastic to see our students learning world-class computational engineering tools that can help in their academic and real-world engineering practices,” Professor Marzocca said. “It’s another example of RMIT embedding industry into everything we do and our commitment to providing students the best tools available to get them industry ready.”

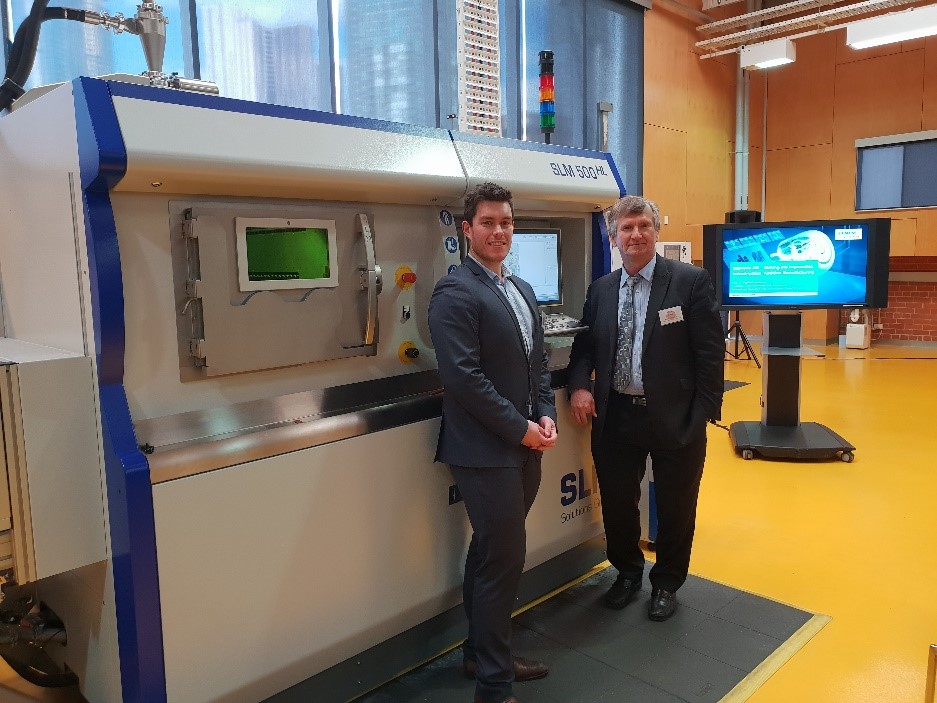

As global industry pushes for lean manufacturing techniques, faster prototyping and light weighting of optimised structures, additive manufacturing is now becoming a mainstream manufacturing technology globally and the design tools are a critical element of the process chain.

Advanced Manufacturing Precinct Director Professor Milan Brandt said he was excited about how the software could link high-end product design capabilities with high-end manufacturing techniques.

“This software gives us access to the design tools and enable the ability to incorporate new manufacturing methods into prototyping and serial production,” said Brandt.

RMIT students and staff in the College of Science, Engineering and Health will get unlimited access to high-end simulation software used by engineers across the world under a first of its kind agreement in Australia with global company Altair Engineering.

The technology is used by companies including Boeing, BAE, Telstra and GM Holden to reduce the weight of aeroplane and automotive structures, make Japan’s high-speed bullet trains safer, develop ultra-light bikes and drones, create wireless sensors that detect damage to planes from lighting strikes and for simulating bio-electromagnetic effects.

It’s the first time American-based Altair has worked with an Australian University to enable access to its engineering software programs for teaching and non-commercial research use and the agreement is another great example of RMIT’s commitment to delivering industry-ready graduates.

The agreement is the brainchild of Joel Kennedy, an RMIT alumni and Project Engineer at Altair.

“RMIT had previous, limited access to the software. Students are currently using the simulation software as part of RMIT Combustion and Electric Racing, which competes in the Formula SAE competition, and the RMIT unmanned aircraft systems research team, which has seen staff and students showcase high-tech autonomous drones in overseas competition,” said Kennedy.

“I used some of the design software during my studies but wasn’t taught HyperWorks. Now working with it, I can see the level of impact it has in industry and it will only continue to grow. This campus-wide agreement means students across science, engineering and health courses can access world-class engineering tools,” he said.

Associate Dean of Aerospace Engineering and Aviation Professor Pier Marzocca welcomes the agreement.

“From few users to many, it is fantastic to see our students learning world-class computational engineering tools that can help in their academic and real-world engineering practices,” Professor Marzocca said. “It’s another example of RMIT embedding industry into everything we do and our commitment to providing students the best tools available to get them industry ready.”

As global industry pushes for lean manufacturing techniques, faster prototyping and light weighting of optimised structures, additive manufacturing is now becoming a mainstream manufacturing technology globally and the design tools are a critical element of the process chain.

Advanced Manufacturing Precinct Director Professor Milan Brandt said he was excited about how the software could link high-end product design capabilities with high-end manufacturing techniques.

“This software gives us access to the design tools and enable the ability to incorporate new manufacturing methods into prototyping and serial production,” said Brandt.