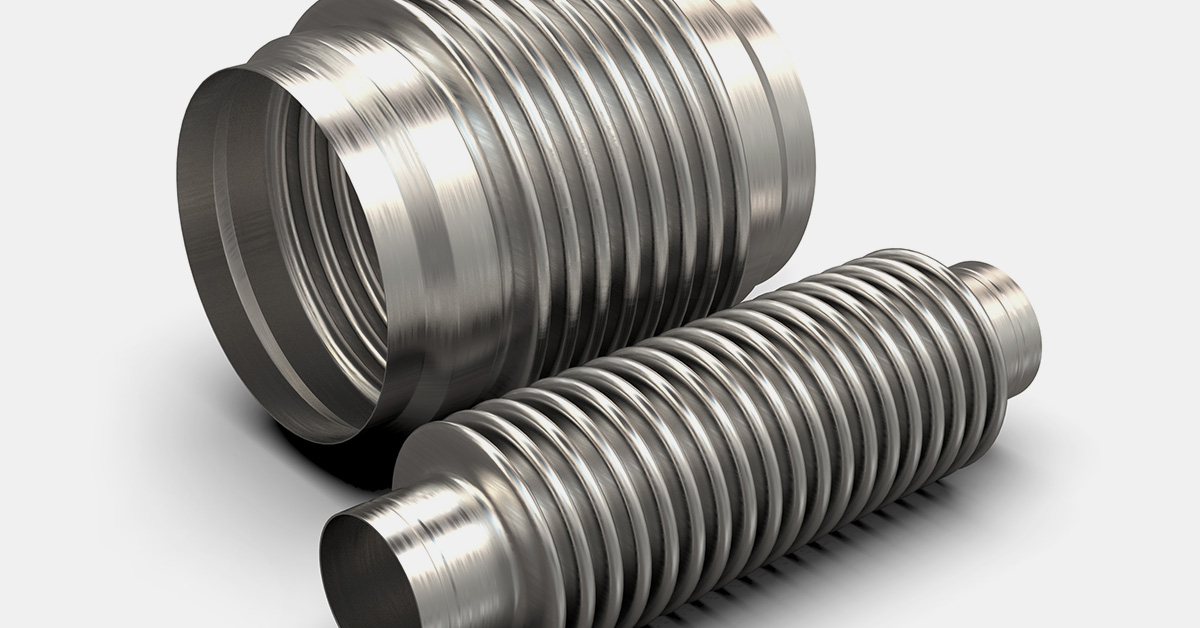

Custom Bellow Forming Simulation - Altair HyperWorks Helps Interlaken Conduct Efficient Bellows Forming Simulation

Interlaken were awarded projects to develop processes and tooling for manufacturing bellows – accordion-like devices used often in rocket propulsion systems – from tubular stock for aerospace OEMs. To ensure the production of high-quality bellows with minimal development costs and time, Interlaken needed to study the bellow forming process for various tool geometries, tool kinematics, process conditions, and stock tube geometry and material. To shorten this process and minimize physical prototyping, Interlaken decided to work with Altair. Together, they set up a bellows forming process simulation comprising a multi-layered tube using Altair HyperForm, Altair Radioss, and Altair HyperView to visualize and analyze finite element analysis (FEA) results through a guided 3D workflow.

With Altair’s simulations tools, Interlaken team was able to iterate upon several design concepts, optimize the forming process, and compensate the tools for springback to manufacture high-quality parts – all while meeting design goals, minimizing costs and effort, and speeding time to market.