DEM-led Digital Twin for Blending Unit Operation in Pharmaceutical Manufacturing

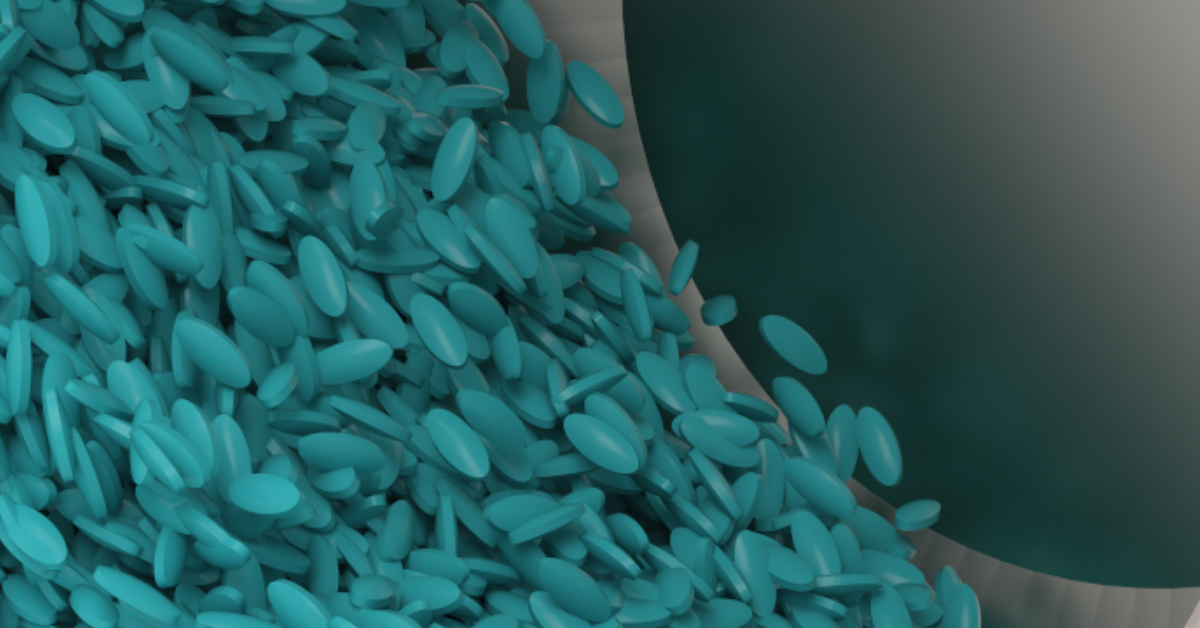

In pharmaceutical manufacturing, the blending operation plays a critical role in ensuring the uniformity and quality of the final product. Traditional methods of process optimization and quality control can be time-consuming and often incur huge operating and batch failure costs. This presentation explores the application of Altair EDEM, a particulate simulation software, in creating a Digital Twin for the blending unit operation in pharmaceutical manufacturing. By integrating romAI with advanced simulations, a Digital Twin model is developed that mirrors the physical blending process. This model allows for dynamic analysis of particle interactions, blend uniformity, and the influence of operational parameters such as mixing speed, load, and time. Through this virtual representation, manufacturers can predict blend consistency, optimize process parameters, and mitigate risks associated with product variability. The approach enhances process understanding, reduces the need for extensive & expensive physical trials, and ensures compliance with stringent regulatory standards. The integration of Altair EDEM-led Digital Twin technology represents a significant step toward more efficient, data-driven, and adaptable pharmaceutical manufacturing processes.

Presented by Mohan Nainegali, Solutions Specialist - DEM Technology at Altair as part of the virtual event: DEM Simulation for Pharmaceutical Manufacturing Processes - Latest Advances, Methodologies & Applications in June 2025.