Model-based Solutions to Advance Small Molecule Solid Dose Development and Manufacturing

Dr. Rohit Ramachandran, Professor, Dept. of Chemical & Biochemical Engineering at Rutgers University presents at the 2024 ATCx DEM.

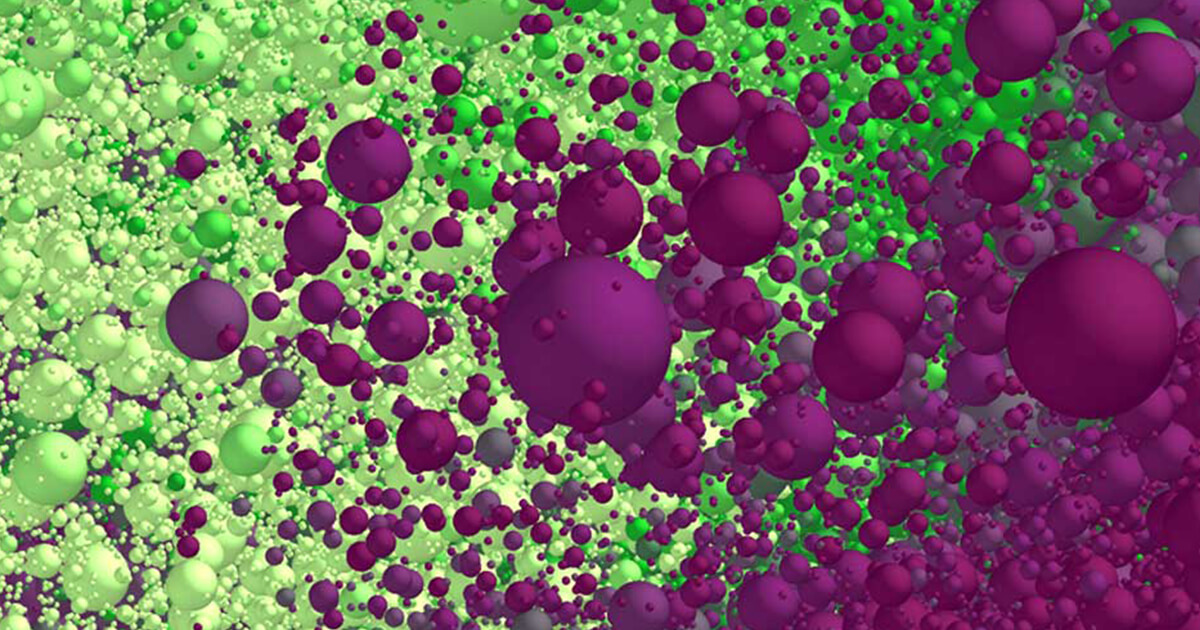

The development and manufacturing of small molecule solid doses is a complex process that can benefit significantly from the development and deployment of model-based approaches. This work explores the development/application of mathematical process models to enhance product and process understanding, enabling more efficient development and optimization of solid dose pharmaceuticals. The use of mechanistic models such as Discrete Element Method (DEM) and Computational Fluid Dynamics (CFD) provide detailed, physics-based simulations of particulate and fluid dynamics, offering insights into material behavior and equipment performance. Semi-mechanistic models, often described by systems of differential equations, combine first-principles knowledge with empirical data, providing a balance between accuracy and computational efficiency. In addition to these, statistical models play a critical role in identifying key process parameters and their interactions, facilitating design space exploration and process robustness. Machine learning (ML)-based models, both data-driven and physics-informed, offer novel opportunities to capture complex, nonlinear relationships within high-dimensional datasets, enhancing predictive capabilities in the absence of comprehensive mechanistic understanding. Hybrid models, which integrate mechanistic and ML-based approaches, further extend the capabilities of process models by leveraging the strengths of both physics-based and data-driven frameworks. The adoption of these diverse model types can significantly improve process control/optimization, quality assurance, and risk management, resulting in enhanced performance and reduced time-to-market. By supporting data-driven decision-making and optimization in advanced manufacturing, model-based solutions offer a pathway to more agile, efficient, and cost-effective pharmaceutical production.