Optimizing a Hot Mix Asphalt Mixer using DEM and Machine Learning

Presentation by Dr. Andrew Hobbs, Head of Simulation and Modeling at Astec Industries.

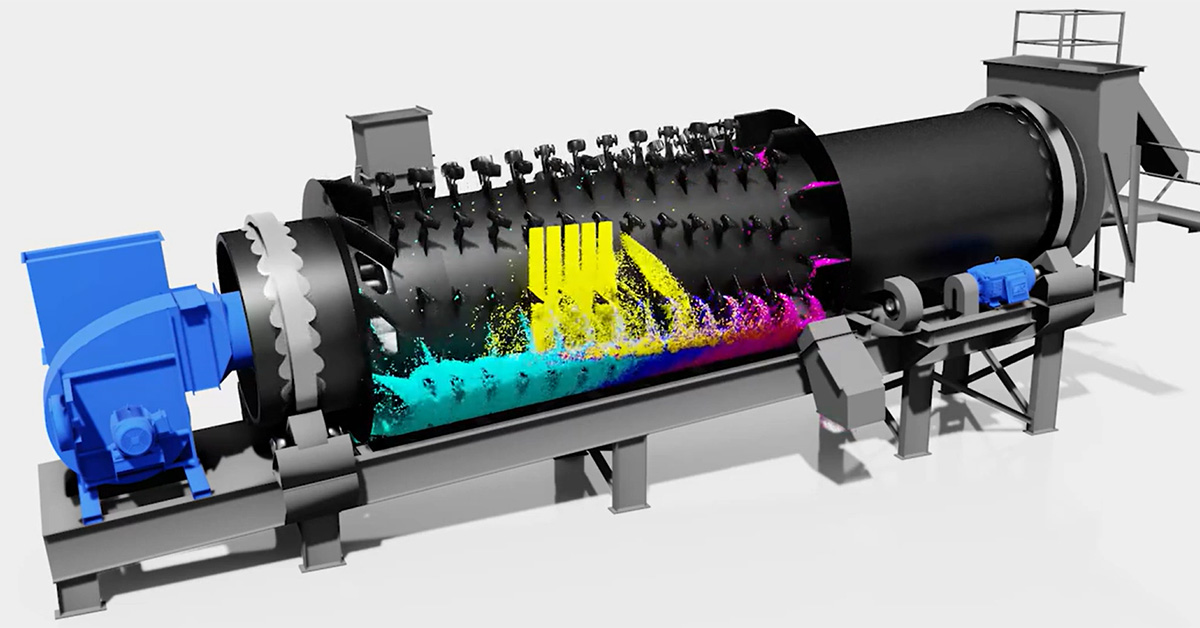

Efficient mixing of reclaimed asphalt product (RAP) is a crucial part of the process of making hot mix asphalt more sustainable but the traditional optimization approach, which is heavily reliant on physical trial-and-error, is prohibitively time consuming and expensive. Optimization using simulation provides a significant advantage. This work demonstrates an efficient methodology for virtual design optimization that combines high-fidelity physics-based simulation, High Performance Computing (HPC), machine learning and optimization to rapidly identify the globally optimal equipment design.

The methodology consists of parametrizing the equipment geometry, automatically generating and running Discrete Element Method (DEM) simulations for a well distributed quasi-random sample of the geometric parameter space on the cloud and fitting a response surface to the results using machine learning. A Multi-Objective Genetic Algorithm (MOGA) is then utilized to rapidly estimate the globally optimal parameter set from the fitted response surface. Optima from the MOGA were verified and a new mixer configuration was identified which provides similar mixing with fewer paddles, lower torque, and greater mass flow representing a superior design.