Unveiling Powder Bed Homogeneity in Additive Manufacturing: Numerical and Experimental Insights through Multi-Layer Spreading

Dr. Ratna Kumar Annabattula, Professor, Department of Mechanical Engineering at IIT presents at the 2024 ATCx DEM.

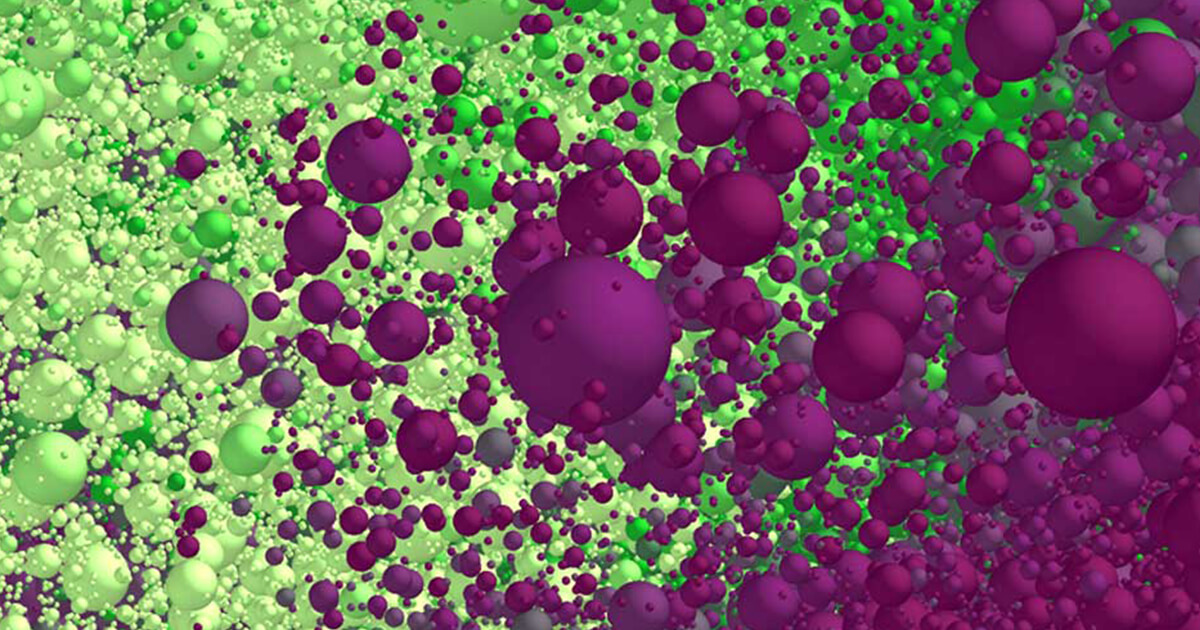

MadrasLaser Powder Bed Fusion (LPBF) additive manufacturing utilises metallic powders to create components with exceptional dimensional accuracy. Components are manufactured by spreading powders and selectively fusing them with a laser beam in a layer-by-layer fashion. Powder spreading is the most critical powder bed fusion additive manufacturing process. Achieving a uniform and homogeneous powder bed under various process parameters is crucial for ensuring high-quality final components in LPBF. Experiments revealed significant variations in particle size distribution, particularly in the extreme zones of the spreading platform, indicating segregation within the powder bed. Scaled DEM simulations were carried out to analyse the multi-layer spreading process. The simulation results reveal the variation in the packing density and particle size distribution in different zones of the spreading platform. The variation in the packing density with the number of layers spread is also investigated. The influence of the recoater geometry on the powder bed quality will be discussed. The results from this research provides detailed insights on the influence of process parameters such as dosing factor, first layer thickness and recoater velocity on the powder bed homogeneity. The findings contribute to a better understanding of the powder spreading mechanism in LPBF and provide insights to improve the overall bed quality.