Using Altair EDEM in the Design of Construction and Mining Equipment

Watch examples of applications of EDEM in the design of dump trucks, excavators, loaders, grab buckets, and more.

EDEM software, powered by the Discrete Element Method (DEM), accurately simulates the behavior of rocks, soils, ores and gravel, etc. It provides engineers with crucial insight into how materials will interact with their equipment during a range of operating conditions, and enable them to use realistic loads in Finite Element Analysis and Multi-body Dynamics simulations for optimal designs.

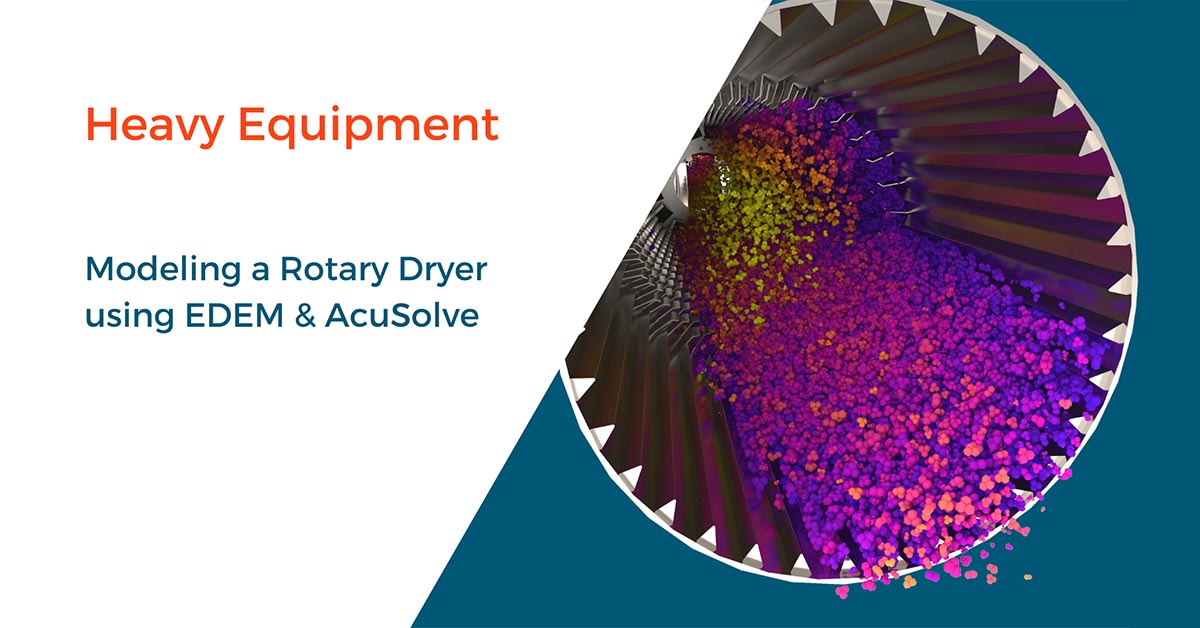

Modeling a Rotary Dryer using EDEM and AcuSolve

Rotary dryers are used to dry bulk materials in a wide range of industry applications including road making, agriculture or chemicals. While being a very common process, there is significant potential to optimize the energy usage and material throughput. In this example, EDEM and AcuSolve are used to model the dryer and the drying, which allows to optimize its operational parameters, feeding rate and lifters design to maximize its efficiency and performance.

Grab Bucket Simulation using EDEM Coupled with MotionSolve

In this video EDEM is coupled with MotionSolve to better understand and predict the performance of a grab bucket handling different materials. Critical information on how the equipment responds when interacting with the bulk material can be obtained such as force and torque acting on different parts as well as the stress on components.

Dump Truck Loading Analysis Using EDEM and OptiStruct

This video shows how EDEM can be used to understand and predict the behavior and impact of different bulk materials like gravel, clay, tar and grass on a dump truck. EDEM provides accurate contact forces data that can be used to run finite element analysis using OptiStruct.

Road Grader Simulation using EDEM

This video produced in collaboration with Xuzhou Construction Machinery Group shows how EDEM software can be used to simulate grader applications such as flattening, ditching and scraping. Ground particles can be colored by velocity, layers and position to enable analysis. Additionally, data for the grader blade can be obtained such as wear, pressure and forces allowing equipment optimization.

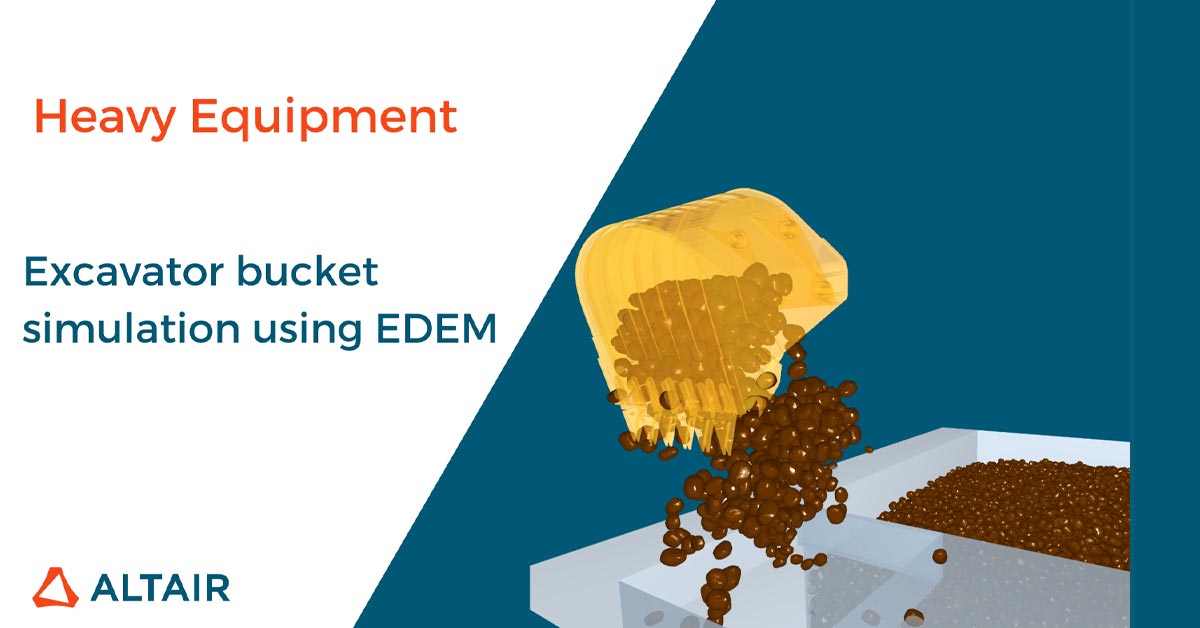

Excavator Bucket Simulation using EDEM

EDEM can be used to optimize the design of excavator buckets - providing key insight into equipment performance. Different designs can be compared for handling a range of materials such as rocks, gravels or more cohesive materials. Key information on loading time, spillage and wear can be visualized and analyzed – enabling more design optimization improvements to be made.

Simulation of Dump Truck Unloading Material into Hopper using EDEM

EDEM can be used to aid the design process of dump truck bodies. Realistic material modeling allows users to test dump truck performance in different operating conditions by analyzing loading/unloading patterns or pressure distributions.

Designing Faster, Lighter Equipment

Nemag BV is a manufacturer of grabs designed for handling a range of bulk materials. Nemag worked with TU Delft to develop a new generation of grabs for iron ore that are faster and lighter – using Altair EDEM bulk material simulation software to test and optimize the new design.

Read Customer StoryDesigning Construction and Mining Equipment with EDEM

In this webinar, learn more about EDEM software and how it can be used for the design, performance testing, and optimization of mining and construction equipment.

View WebinarApplications of EDEM for Construction and Mining Equipment Design

This eBook discusses the challenges linked to designing equipment intended to handle rocks, soils, ores and gravel. It introduces EDEM and explains how it can be used for the design, performance testing, and optimization of construction and mining equipment.

Read eBook