Virtual Weld Certification

Welded assemblies are used widely across industrial sectors. The design processes in rail, construction, heavy machinery, and many other industries rely heavily on regulations, codes, and norms such as FKM, DVS-1612, and Eurocode-3. Identifying the local degree of utilization of weld connections in accordance with individual or industry guidelines can become a challenge. A fast, automated, and practical fatigue strength verification for mechanically stressed components accelerates the design process significantly.

Certification of Welded Structures

The evaluation and standard-based certification of welded construction is a repetitive and time-consuming process.Altair HyperLife™ addresses the challenges of weld inspection by combining CAE methodology with relevant norms and regulations in a guided and standardized workflow. This includes model preparation and verification calculations, as well as the generation of reports for documentation, making the analysis of welded joints easier, faster and more robust. Altair HyperLife provides a standard process and platform to handle changing product configurations.

Learn MoreRapid Design Iterations of Welded Assemblies

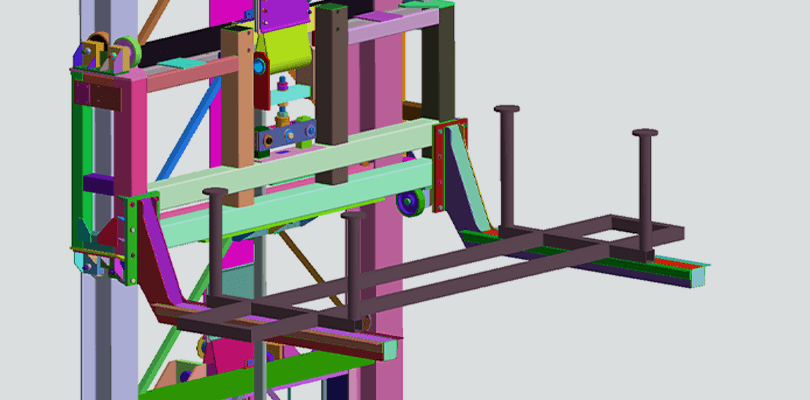

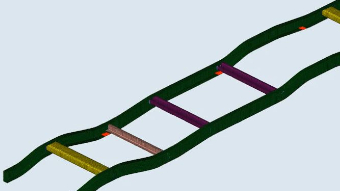

By performing structural analyses on fully featured CAD assemblies within minutes, Altair SimSolid™ is a game-changing simulation technology for designers, engineers, and analysts. It eliminates geometry preparation and meshing: the two most time-consuming, expertise-extensive, and error-prone tasks performed in a conventional structural simulation. SimSolid can create seam welds directly from polyline definitions or from legacy data to enable program teams to perform fast and accurate seam weld design studies on large assemblies.

Learn MoreHow can we help you to accelerate your virtual weld assessment?

Contact Us

Accelerate Manual Processes

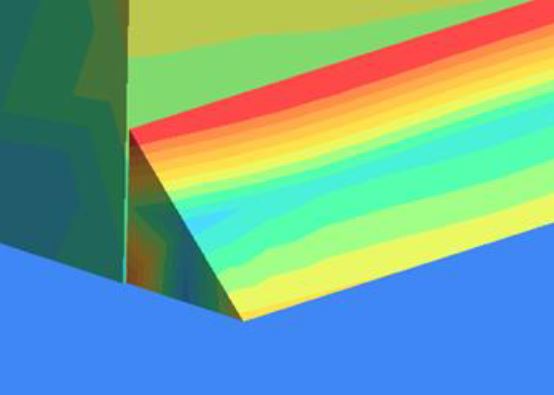

Altair HyperLife™delivers robust fatigue strength assessments for welded structures. It identifies and classifies weld lines across an entire structure then checks for fatigue issues throughout a structure and across multiple joint types, providing a consistent and efficient method to run a full weld line verification process. It delivers a competitive advantage to organizations that want understand influence of weld lines on product performance and need to perform weld line certifications.

Comply with Norms and Regulations

The implementation of norms and regulations for the assessment of welded structures in the open architecture of Altair HyperLife™ enable evaluations according to defined standards, as well as individual methods. The supported norms and regulations include:

- DVS 1612 for weld seam evaluation

- EuroCode 3 for the evaluation of welds and the evaluation of the base material

- FKM guideline for the evaluation of welding seams and evaluation of the base material

Deploy Virtual Weld Certification

Altair's team will work with you to understand your individual unique operating practices to ensure that your process meet your requirements.

Our experts can:

- Evaluate current methods for modeling and simulating weld lines

- Align the automation solution base module accordingly

- Provide quick-start focused support and periodic checkpoint assessments to ensure a successful user experience

Featured Resources

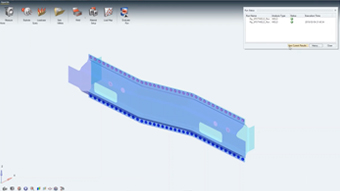

Altair SimSolid™ – 3D Solid Seam Welds

Seam welds are now modeled as 3D solids. This replaces the previous connection based approach. Welds are defined by section size and length along the edge. Simple trapezoidal shapes are used to represent the welds. Weld material properties are taken from the adjacent parts.

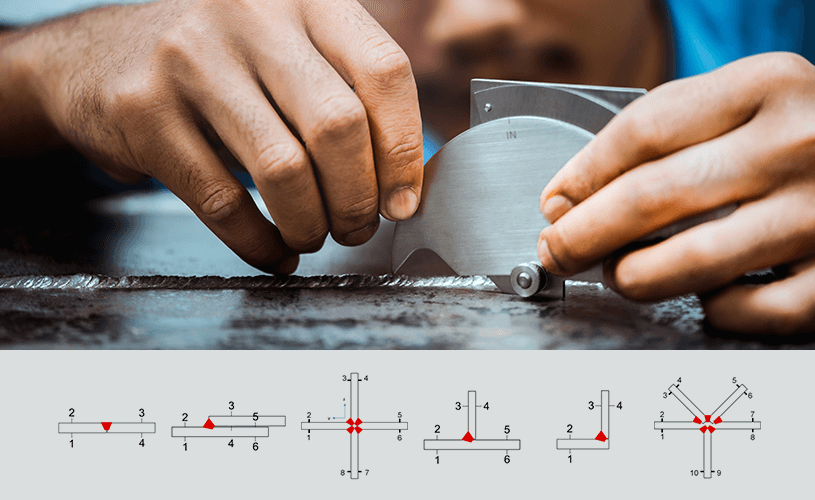

Altair HyperLife Seam Weld Fatigue Analysis

Structural stress method implementation for Seam welds idealized with plate or shell elements. The approach is based on VOLVO method. Supported weld type is FILLET weld and the weld lines (root and toe) are automatically identified.