Aerospace Startup Acceleration Program (ASAP)

Altair believes in those who dare to push the limits of engineering to change the world. That’s why we support startups in their challenging journey towards success through the Aerospace Startup Acceleration Program (ASAP), an acceleration program designed to help startups overcome the aerospace industry’s unique hurdles.

We know that developing, testing, and certifying your minimum viable product (MVP) as soon as possible – without financial trade-offs early on – is a top priority. Market-leading design, simulation, engineering, artificial intelligence (AI), and data analytics tools can drastically accelerate your journey, reduce risks and costs, and ensure your team makes data-driven decisions quickly.

What Makes ASAP Different?

Altair designed ASAP to meet the unique needs of the aerospace industry. As a startup, every penny counts – and obtaining the right tools can be very costly, requiring you to allocate precious capital on software instead of people. ASAP ensures you’re maximizing your investments across the board.

In addition, many startup programs from other companies have major drawbacks: they often last only a few years, which isn’t enough time for most aviation startups to get off the ground. They can also lock you in with attractive initial offers and then increase prices too soon — regardless of your financial condition.

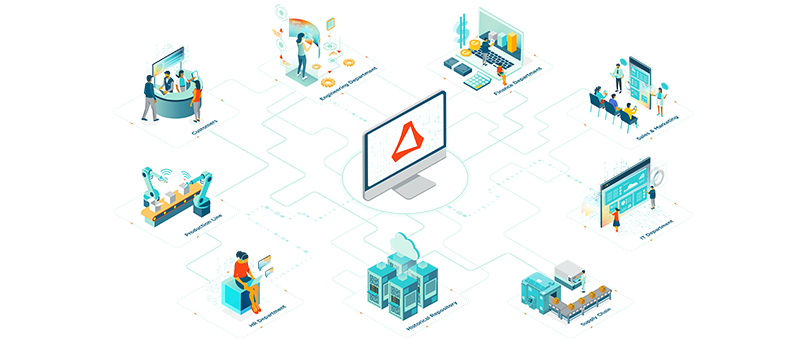

With Altair, you get flexibility and peace of mind. You can use our solutions along with in-house code, open-source tools, or software from other companies; Altair’s tools are interoperable and easy to connect to other systems.

Apply for this Altair Startup Program package today.

Apply NowUnlimited Simulation and Data Analytics Software

Your cost for access to all our design and simulation and data analytics software is a small percentage of your total funding, recalculated annually. This gives your team access to all the software they need, wherever they work. In short, you get the same access to the software trusted by major aerospace organizations around the world.

Unlimited Training

To shorten your team’s learning curve, you also get 24/7/365 access to the Altair Community and support resources. All our resources offer an easy-to-understand interface that gets your team up to speed quickly.

Looking to enhance the performance, efficiency, and safety of your aerospace and defense sysems?

Get StartedFeatured Resources

Startup Innovation: Building the Future of Space Panel Discussion

Panel discussion presented as part of Altair's Future.Industry 2025 conference.

Moderator: Paolo Colombo, Director of Strategy, Aerospace & Defense at Altair

Panelists:

Dr. Giuseppe Borghi, Head of the Φ-lab Division at ESA

Cornelis Eldering, Head of ESA Entrepreneurship & Business Incubation Services at ESA

Felix Motzki, CTO of Reflex Aerospace

Farouk Haidar, Structures Engineer at ATMOS Space Cargo

This panel discussion will bring together leaders from space startup companies along with the European Space Agency, to discuss how digital engineering plays a critical role in their product development, the transformative potential of AI, and how these advancements are shaping the future of space exploration and commercialization. The conversation will provide insights into where the industry is headed, and the opportunities and challenges facing startups in today’s highly competitive space sector.

Meridian Flight Systems Joins Altair Aerospace Startup Acceleration Program

Within ASAP, Meridian will utilize Altair’s next-generation simulation, data analytics, and HPC software and technical support to enhance the development of the Corra unmanned aerial vehicle (UAV) and its Hybrid Electric Rang