Breaking Total Internal Reflection (TIR): Is it against the law?

The quick answer is, of course not. The first question really should be, what is TIR. TIR stands for Total Internal Reflection, and is the guiding principle of fiber optics, light guides, and light pipes for use in applications such as automotive interior lighting, computer displays, consumer electronics, aviation displays, and many other areas. TIR means that light rays that meet certain conditions are reflected inside of a light guide with no loss in flux or power. This is great when transmitting light from one point to another where little or no loss is important. There are other cases though, such as displays and indicators, where it is desirable to get the light out of the light guide at some user defined position. This is where breaking TIR is appropriate.

When we break TIR we are in fact breaking a law, in this case Snell’s Law. Snell’s Law governs how light is refracted or bent when it goes from one medium to another. For example, for air into plastic, or from plastic back into air. Snell’s Law is: n1sinθi = n2sinθt where:

- n1 = index of refraction of incident material

- n2 = index of refraction of transmitted material

- Θi = incident angle

- Θt = transmitted angle

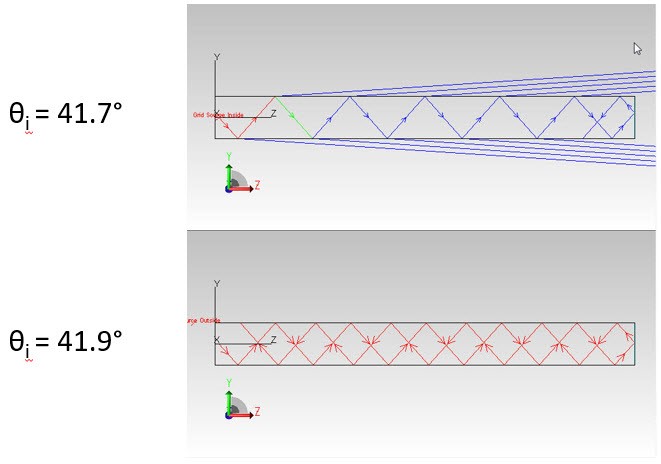

Figure 1: Ray in a light guide, greater than and less than critical angle

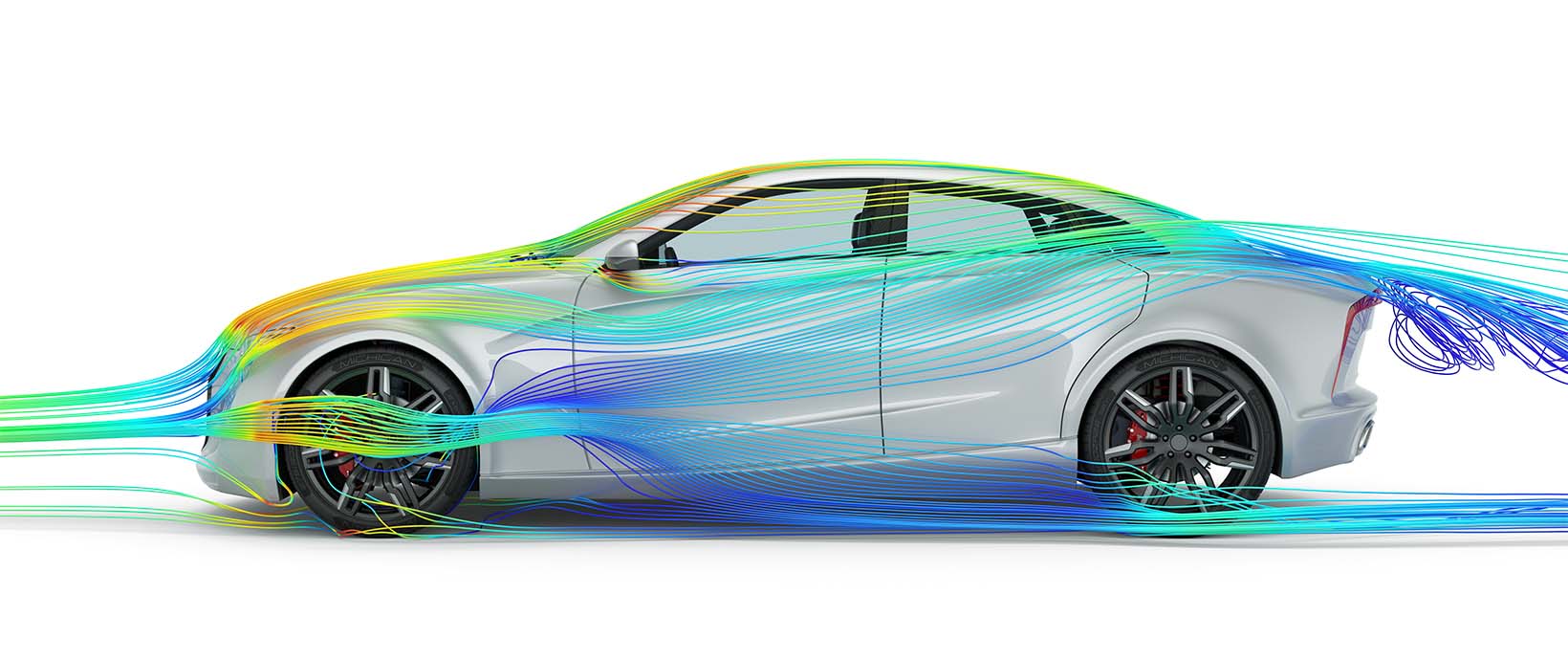

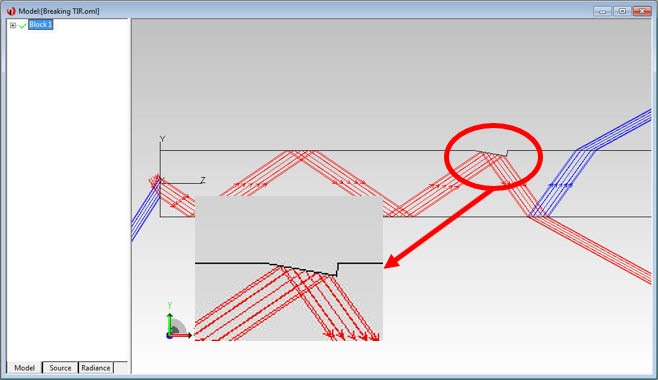

As mentioned earlier, sometimes it is necessary to break TIR to direct light in a specified direction. Examples of this would be for a backlight or a display ring. A couple of ways of breaking TIR are adding surface features or surface textures to the light guide. Figure 2 shows an example of adding a geometric feature to the light guide to break TIR. This method may be used in a backlight light extractor. The red rays in this example have higher flux or power and the blue rays have lower flux.

Figure 2: Using a geometric feature to break TIR

Figure 3 shows an example of adding a texture to the exit surface of a light guide to break the TIR and facilitate getting light out of the light guide. This could be done by molding a texture on the surface of the light guide or by apply a ground glass type finish to the surface.

Figure 3 : Surface texture used to break TIR

Translucent paint on the surface of a light guide can also be used to break TIR. Some examples of this would be indicators and logos using a laser etched paint method. Figure 4 shows an example of a plastic light guide with a company name and logo using a black laser etched paint with a red paint under the black paint and white LEDs.

Figure 4: Light guide with laser etched paint

One additional method that could be considered is to add a diffusing or scattering material into the plastic light guide when it is being molded. This causes the light to scatter inside the light guide and break the TIR by making the rays hit the surface of the light guide at less than the critical angle. Figure 5 shows an example of a light guide with a diffusing material added to the plastic.

Figure 5: Light guide with diffusing material added

As can be seen, despite sounding like a risky endeavor, breaking TIR is actually a useful tool that can be used by optical engineers and lighting designers to create light guides to meet a wide range of requirements. There are numerous ways that features can be added to the light guide to break TIR and many of these features lend themselves to high volume manufacturing. Learning how to control TIR is a great skill to develop and has numerous applications in light guide, backlight, and display applications.Learn more about APA partner Lambda Research Corporation, here.