How Optimization of Geometry Aids Streamlining of CAE Data Preparation

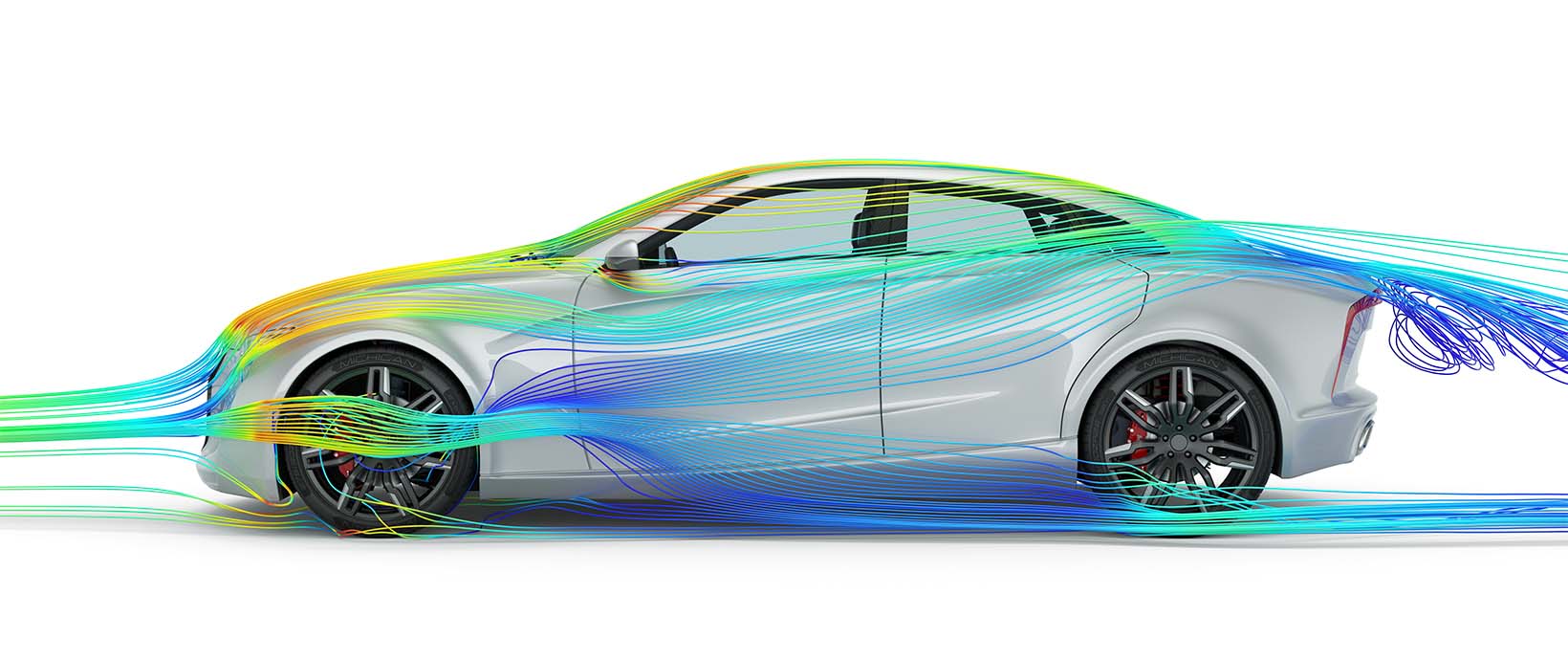

The CAE process is an important step within the product manufacturing lifecycle. Specific data formats are required and in the world of FEM analysis, meshing is a primary step towards sending your data to solvers for analysis such as structural and heat transfer analysis. Solvers and meshing software have become more advanced throughout the years realizing more efficient and accurate simulation results and cutting down costs for manufacturing parts and the like.

As 3D models are utilized more frequently and in various situations, it is more necessary than ever before to prepare quality assured data (more information about data interoperability and data quality could be found in the blog post, “CAD Data Quality and its Importance in Downstream Data Interoperability”). It goes without saying that getting the right format and acquiring high quality data is of utmost importance for CAE data preparation, but optimization of the geometry also plays a crucial role in attaining CAE results.

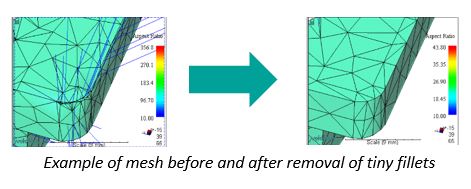

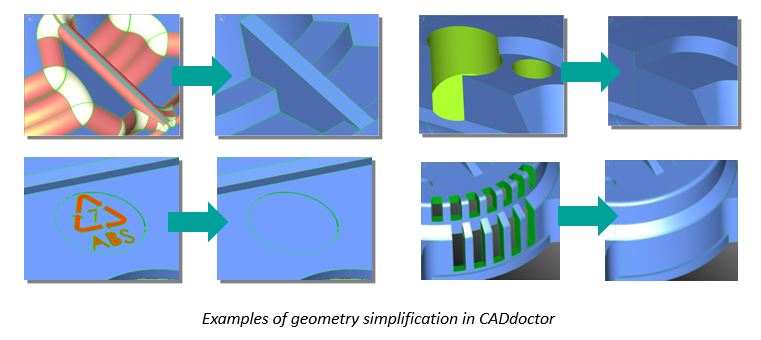

One of the geometry optimization examples that are often examined is to remove unnecessary features from the geometry that is often not needed for the CAE process. This is commonly referred to as “Geometry Simplification” and it is often the case that without geometry simplification, the calculation time for meshing and solving accumulates, creating longer lead times. This is because taking highly complex geometry directly into meshing causes rework for engineers to repair elements inside of the meshing software. Tiny fillets and thin faces are just a couple of things that could cause inability and poor quality meshing, leading to inaccurate and lengthy calculation.

To avoid a nightmare, engineers could refer to their CAD systems and run through the history tree for removing features. This procedure is not very straightforward as the more complex the model becomes, it will be increasingly more difficult to find the appropriate features to suppress. Even if the features are found, the complication of the history makes it difficult for a successful removal. Also, it is often the case that the already prepared data for meshing has been exported as an intermediate format such as STEP or IGES. This implies that design history information is no longer intact and another method is required.

As introduced in the previous blog, CADdoctor offers high-quality translation and healing technology based on over 30 years of experience handling sophisticated geometry. Not only that, but CADdoctor also includes simplification technology to detect and remove features. Fillets of course, but small holes, bosses/ribs, steps, and logos can all be automatically recognized and removed with ease.

Check out the webinars/videos below for an introduction to CADdoctor and its use cases as well as a workflow using CADdoctor’s robust geometry simplification function and HyperMesh’s meshing capability.

Arkal Automotive Case Study Video

Optimizing your CAE Data Preparation with HyperMesh and CADdoctor

CADdoctor Use Cases for Ideal CAD Data Preparation