Materials Databases: Supporting CAE Simulation and Keeping Pace with Evolving Technologies

This guest contribution on Innovation Intelligence is written by Neil Baumann, COO at Key to Metals AG. Total Materia by Key to Metals is the world’s most comprehensive materials database with over 10 million property records spanning over 380,000 materials. Total Materia is available through the Altair Partner Alliance.

Introduction

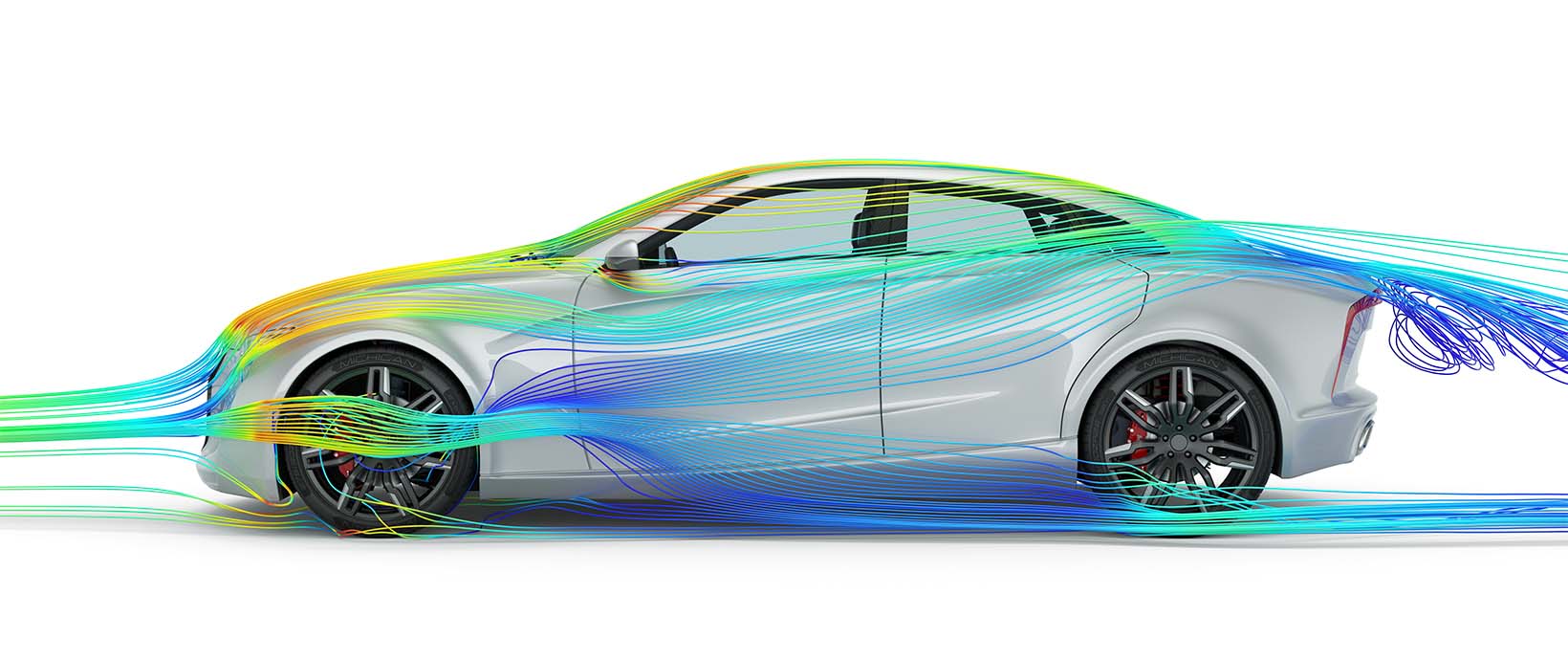

The importance of accurate material properties information for engineering calculations and simulations, such as CAE (Computer Aided Engineering) and FEA (Finite Element Analysis), can never be overstated. Conventional mechanical properties such as yield strength, tensile strength, hardness, and ductility may vary more than tenfold for structural steels at room temperature, depending on the variations of alloying elements, heat treatment and fabrication. With even a moderate change in working temperature, the properties’ variations and changes can become even more profound and their approximation using the typical property values for some groups of alloys may lead to very serious errors.

Serving the Engineering Design Workflow

Information about materials and their properties can be used in diverse engineering activities, but three use cases can be emphasized as typical:

- Selection of a material starting from a required set of properties and conditions

- Choosing the best alternative within a large or small group of materials

- Extracting detailed property information for a defined material.

The first use case can be relatively straightforward. This can be attained by combining the values of various mechanical and physical properties to define conditions that the material needs to fulfill. Optionally, the content of some alloying elements or, in case of reverse engineering, complete chemical composition can be specified as well. As a result, a list of materials is obtained that may have a few or up to several hundred materials.

The second use case may come in the workflow either after the first case or independently. It implies starting from a group of materials and then comparing and analyzing their properties in order to find the most convenient material for a given application. Materials can be compared in a variety of ways, from an entire material property dataset side-by-side, to comparison of selected properties in one or two dimensions, to comparing various curves and multipoint data. In Total Materia for example, alternative materials can be further explored using cross-reference tables, a patented SmartCross algorithm or Equivalence Finder.

The third use case can again come either after the second case in the simulation workflow or independently. The material properties of interest can be highly diversified depending on the application and the following section of this blog describes some the material properties related to forming.

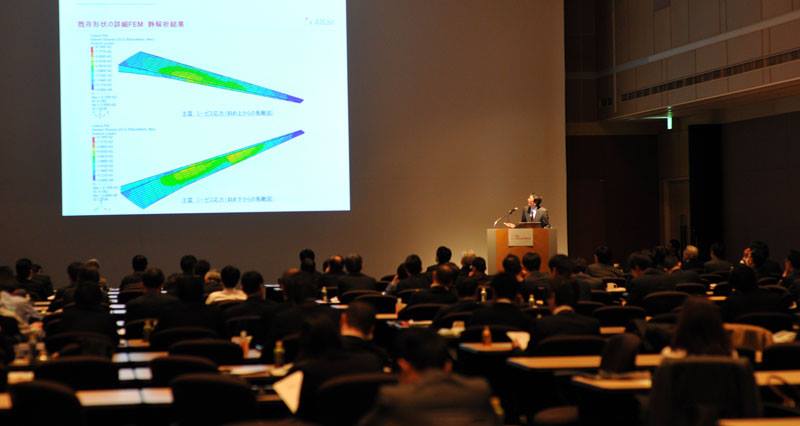

Application Case: Material Property Information for Forming Simulations

Besides linear mechanical and physical properties on various temperatures, non-linear and plastic properties are of particular interest for accurate simulations of forming. Unfortunately, this advanced mechanical properties information is typically very hard to find due to general scarceness of published experimental data, especially when various conditions of temperature and velocity of deformation are considered.

To overcome this problem, in the process of database development, as in the case of Total Materia, over 2,200 data resources have been acquired, ranging from relatively large data collections to individual papers dating back from over 60 years ago to more recent articles. In addition, a proprietary methodology has been developed for integrating raw data obtained from diversified experiments from all over the world, consisting of a specific set of algorithms for data selection, processing and assessment for each of the five advanced properties modules.

The resulting database contains direct stress-strain curves and formability data for more than 12.000 materials, and is updated monthly.

The future is now…

An increased usage of Extended Range in CAE analysis has recently led to an increased number of requirements for some form of integration with CAE software. While implementation of such integration and its complexity level can depend on a number of technical and contractual questions, some recent and simpler solutions have been developed in order to provide a higher level of accuracy and time savings to CAE engineers.

As a result, the user obtains a file that can be used directly in the solver, which represents a loose integration, based on file exchange. A stronger integration with CAE tools can be achieved by using API, which can enable users to program and use Total Materia data and functions within the CAE software itself or to automatically update the internal database of CAX software environment

Summary

As a consequence of a permanently increasing demand for accurate and reliable material properties data that can be used for sophisticated CAE analysis and simulations, the Total Materia database has in recent years undergone dynamic development, which includes an increased number of records and materials covered, stress-strain curves and formability data, introduction of new properties and tools for material comparison and selection, as well as integration possibilities with CAE software.

Besides further increase of data included, especially for high temperatures, and new search functionalities, on-going and future developments are focused to further integrate within the design workflow, either with CAX software and simulation tools or with broader PLM and ERP systems, and implementing new exchange formats that prepare for the integration level needed for Industry 4.0.