Parameter and Casting Optimization with Simulation-Driven Casting Design

This guest contribution is written by Hakan Fransson, Technical Manager at NovaCast Systems, a member of the Altair Partner Alliance.

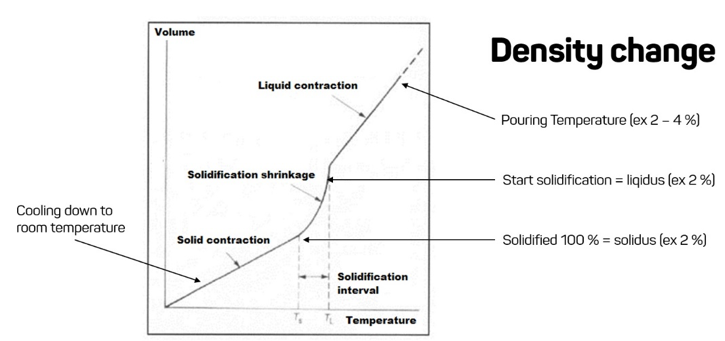

The casting process has been used for more than 5,000 years to produce castings for varying applications. Castings are becoming lighter, stronger and increasingly defect-free, but there remains room for improvement. The higher demands for lower weights and higher quality challenges us to change how to design and produce castings. Until now, casting simulation programs have more or less been used primarily by foundries and not the companies designing the castings. This is rapidly changing. So, why is it complex to cast different kinds of metals? Simply put: density changes when metals transform from a liquid to a solid.

When a liquid melt goes transforms into a solid metal the volume decreases and the density increases.

Typically for steel, the volume reduction from liquid to solid state is 7 percent. This volume decreases the dimensions and also creates ’holes’ in the casting where it solidifies in its final stages.

Simulation-Driven Casting Design

Taking a simulation-driven casting design approach will directly address density changes. To help accomplish this, here are some basic rules that can be applied to make good castings:

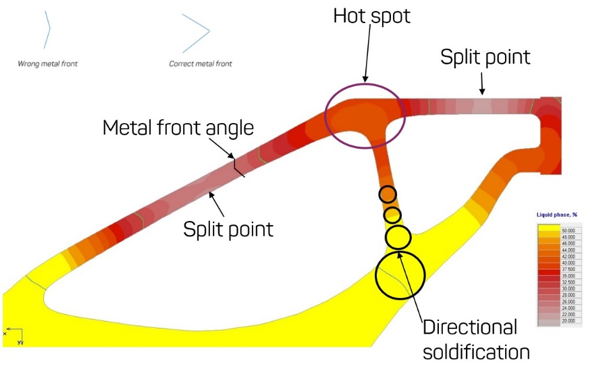

- Find hot spots in the casting and try to eliminate them

- Define melt splitting points

- Design for directional solidification

- Study the metal front angle

The basic design rules when designing a casting include hot spots, directional solidification, split points and metal front angle detection.

By applying these rules, the casting can be more robust to endure the casting process, resulting in better quality products. To dive deeper into this topic, register for our webinar on November 12, 2019.

Parameter and Geometry Optimization

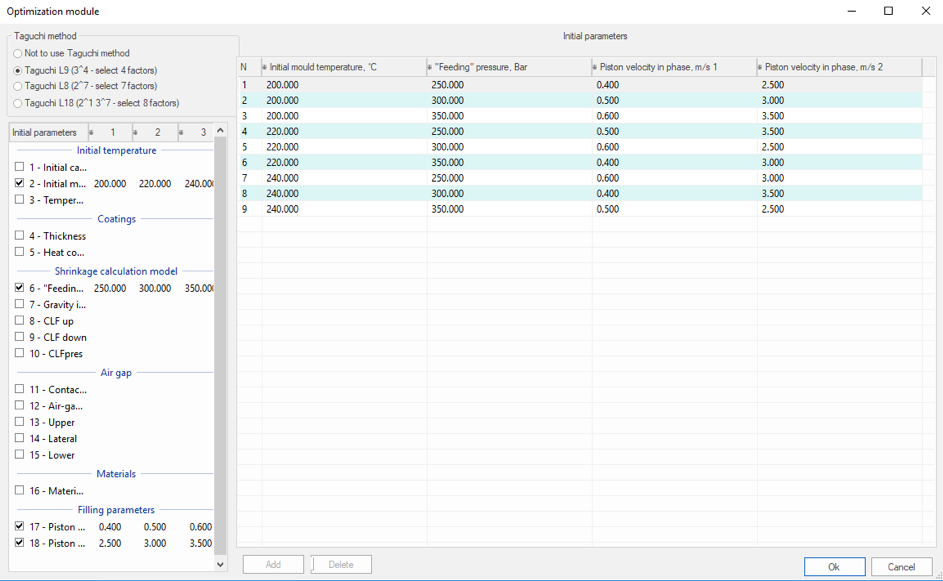

To work more efficiently with casting design development using simulation and applying the earlier described rules, one can use design of experiments (DOE), for example Taguchi Methods. In NovaFlow&Solid the Taguchi methods are integrated with the simulation, allowing the user to set-up structured simulations and run a set of different parameters, like different temperatures, or vary the geometry of the casting to see the differences and select the best option.

The set-up menu for design of experiments and Taguchi methods and what can be set as parameters.

The evaluation can be manual by studying different graphs or tables:

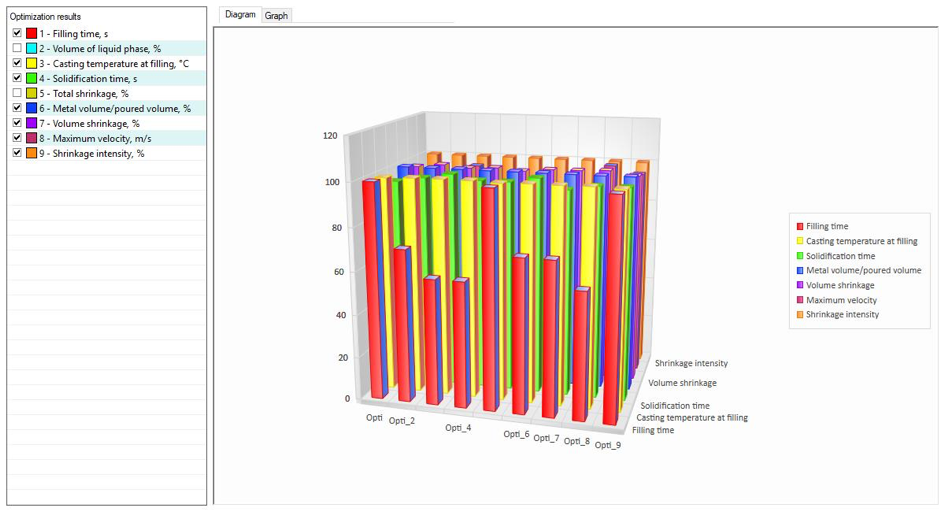

A snapshot of different result fields for different trials. In this way you can judge which one of the trials that is best by simply studying the graph.

Or they are automatically evaluated based on:

- Shrinkage defects in the casting

- How much of the casting that is filled

- Maximum velocity during filling

- Maximum shrinkage intensity

By using these factors, the system itself can find the optimal parameter set or the best casting design.

This way of structured simulations, using the specific rules, shortens the design process and makes the castings easier to produce and gives them greater potential to be higher quality. By Taguchi Trials one can find the best combinations and ways to produce castings that go beyond the manual human approach.