Engineering in the America’s Cup: Creating an Edge with Simulation

To the uninitiated, the word sailing might elicit thoughts of a gentle breeze catching billowing white sails and boats gliding slowly over calm seas. The America’s Cup, one of the world’s oldest and most prestigious yacht race, is a different beast entirely. Boats literally fly, their hulls fully lifted out of the water on narrow hydrofoils. The new 75-foot AC75 foiling monohulls are capable of reaching speeds of more than 50 knots (92 kph). Piloting these vessels takes strength, strategy, and endurance, but in many ways, it’s the team’s designers and engineers that help a winning ship break away from the pack. With the Prada Cup finals beginning February 12, 2021, there’s no better time to take a deeper look at the simulation-driven designs that power these exciting races.

Young America

Altair began its involvement with America’s Cup racing in 1995 as a technical supplier to the PACT95 team. A year after winning IndustryWeek's "Technology of the Year Award" for its topology optimization software, Altair OptiStructTM, Altair consulted and applied this technology to optimize the strength and weight ratios of the hull and appendages for PACT95’s Young America entry.

At this time in America’s Cup racing, the hull structure was the only part of the boat’s design that is secret from competitors. Applying OptiStruct to optimize the best placement for the ring plates and bulkheads yielded a novel inner hull structure design resembling a spider web of trusses. The optimized Young America hull structure provided a clear speed advantage, prompting Team Dennis Conner to use USA-36 Young America in the Americas Cup finals instead of their USA-34 Stars & Stripes.

Although the yacht was defeated by New Zealand in the finals, its technical superiority prompted three American syndicates to approach Altair for help in designing entries for the 2000 race. Altair chose to collaborate with the AmericaOne team spurring a deep technical appreciation, passion, and continued involvement in yacht racing throughout Altair’s operations worldwide.

Artemis Racing

In the 35th America’s Cup in 2017, Altair and Artemis Racing together applied design and simulation technology to help place Artemis Racing in a position to take it all.

The design of the daggerboards – foils that lift the boat out of the water to break the drag barrier – are a critical differentiator between the competing teams as they have a significant impact on a boat’s performance. The Altair and Artemis Racing technical teams placed a great deal of emphasis on perfecting these composite material structures.

“Technology plays a huge part in the America’s Cup. It’s been said the fastest boat has won the America’s Cup for the last 160 years and I’m not sure that is about to change. The daggerboard is the appendage that we fly the boat off and also transfers side force into driving force. Millimeters of difference make knots of difference, so the optimal manufacturing and design of the daggerboard is absolutely critical.”

Iain Percy, Team Manager and On-Water Tactician for Artemis Racing

The teams focused much of their effort on optimizing the strength, shapes, and thicknesses, and how water and wind interact with daggerboards using a simulation-driven design approach involving complex composite material finite element model development, structural and nonlinear large deflection analysis, and optimization.

2021 America’s Cup

2021 brings the much anticipated 36th America’s Cup, as well as a new engineering challenge for the racing teams. Reigning champions Emirates Team New Zealand and their Challenger of Record, Luna Rossa, opted to race monohull ships, a departure from the multihull designs of past races. Altair was named an official supplier for the Luna Rossa Prada Pirelli team and will provide the engineering team of the sailing boat, AC75 Luna Rossa, with simulation software and engineering services.

The catamarans used in the last America’s Cup in Bermuda provided some thrilling races, but their designs were tightly constrained, limiting each team’s potential for technical innovation. In the words of Emirates Team New Zealand's Dan Bernasconi, the defender was keen to push for more differentiation between teams and widening the window of opportunity for design improvements. They chose to come back to monohulls for these reasons, putting their faith in their ability to out-innovate the competition.

Dan Bernasconi Talks AC75 Class Rule Design,” uploaded to YouTube by America’s Cup, July 23, 2020

The new AC75 boats are 75ft long monohull structures, flying above the water balanced on a main hydrofoil and a T-foil Rudder. The windward foil is raised up to act as a counterweight and increase righting moment. As a result of their design, these innovative boats are able to reach the speeds of their multihull contemporaries while offering much greater stability and control.

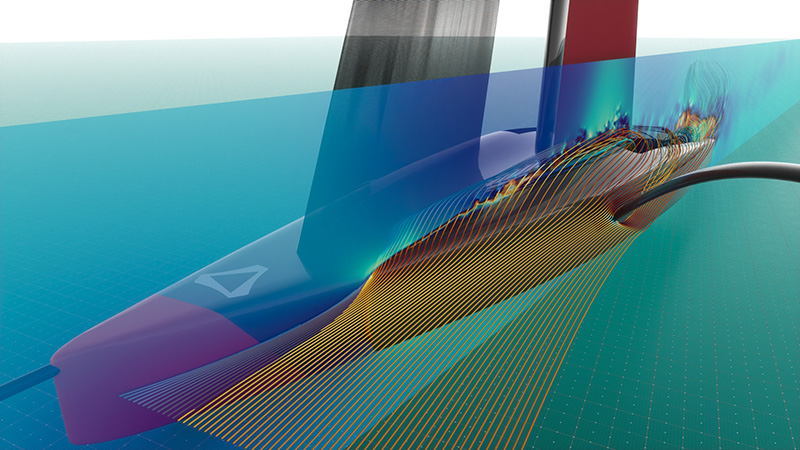

Computational fluid dynamics study on an AC75 monohull boat

When considering an entirely new ship design layout, all of the teams challenging for the America’s Cup had to interrogate the structural makeup of the monohull and understand the complex aerodynamic and hydrodynamic loading conditions the boats would face in operation.

Julien Chaussee, a senior application specialist at Altair and avid sailing enthusiast, decided to create his own AC75 monohull with the assistance of Altair’s topology optimization tools. Rather than focus on detailed component-level design as Altair has done in past projects, Julien focused on applying topology optimization at the concept level to identify main load paths and understand how different load inputs and components interact with each other. In practice this would then be used to define the internal structure and would be refined and optimized further at the next stages of development.

In his study, Julien compared three different design configurations, incorporating a single full-width cockpit and a split cockpit layout as well as looking at a more extreme hull shape.

Through this study, we were able to observe how various design layouts might influence to ultimate performance of the vessel.

Compliance/stiffness results show configuration 1, the split cockpit design, to be the stiffest, though only by 6 percent. This is predominantly driven by the global longitudinal rigidity of the structure. A closer look at the foil and mast area shows configuration 2, the full-width cockpit design, to be better in those regions. Achieving a very rigid midship section would be critical to foils, sails, and systems performance. A stiffer boat does not deform as much when puffs hit and converts the wind energy directly into speed without major losses. Stiffness helps teams harness wind energy more efficiently and assists teams with achieving better wind angles, both of which contribute to a faster boat.

This region would also see a lot of dynamic loads with the big moving foil arms hanging outboard and moving constantly. The structural analysis results observed in this concept study would likely push a team towards configuration 2. This is confirmed by the more extreme configuration 3 which combines the benefits of both earlier designs. In the next steps, engineers would add a more complete set of loads to modify the initial concept and build out the detailed structure inside the hull skin and optimize the overall laminate.

You can take a deeper dive into the preliminary structural design, analysis, and optimization process of sailing yacht hulls in this interview with Julien.

So, as you watch the America’s Cup yachts take flight this March, take note of the incredible feats of engineering that make these races possible. The fastest boat will likely take home the championship as it has throughout the race’s history, and the best application of simulation-driven design will likely be a significant factor in determining who reaches the pinnacle of the sport.