Formnext 2019: From Concept to Production with an Integrated End-to-End Process Chain

When I set foot at Formnext on the first day, I immediately felt excitement and anticipation from my colleagues at the expanded Altair booth before the opening of the fair. The entire show matched this year’s theme, “capability to capacity.” From the novelties, interactive presentations, impressive exhibits, and exciting partner projects, there was no doubt that Formnext 2019 was a successful event.

What's the best manufacturing method for my project?

This key question concerned all Formnext visitors who want to use manufacturing opportunities in an optimal and efficient way, especially for mass production.

To answer this question, tailor-made interactive presentations of an integrated end-to-end simulation process walked booth visitors through defining the first requirements to creating a suitable concept. It also showed analysis of complex structures, up to the simulation of the manufacturing process. Not surprisingly, the Altair Inspire™ live demonstration was the highlight of the Altair booth.

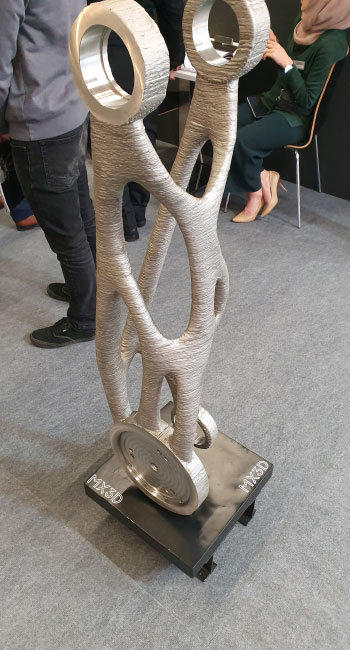

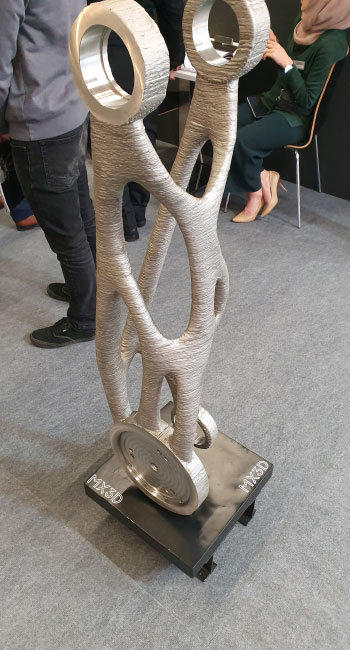

Additive manufactured topology optimization parts that were shown at the Altair booth.

Within the booth area, remarkable exhibits of numerous partners were represented. Partners like amprove, M&H CNC Technik GmbH, MX3D, and Festo, demonstrated how powerful additive manufacturing can be when combined with Altair's simulation solutions.

This applies to all production methods in the field of 3D printing. Whether it's a structure and weight-optimized wheel carrier or a customized 3D printed polymer orthotic for children, combining 3D printing with optimization and simulation techniques can improve the quality of a product and decrease manufacturing time. The displayed applications not only attracted numerous visitors but demonstrated the advantages of combining innovative simulation solutions with advanced manufacturing methods.

Topology optimized robot arm developed with the help of a digital twin design process

Purmundus Challenge: Award of the best

Another highlight of this year's Formnext was the international design contest "Purmundus". Altair, who has been supporting the award for several years, had this year's honor of awarding four prizes as well as launching a category "Simulation-driven Design". 38 finalists in total were competing for their chance to win the challenge trophy. The challenge was moderated and organized by Cirp GmbH, together with the organizers of Formnext.

Additive Manufacturing is growing up

Formnext is an impressive trade fair. This year's exhibition confirmed what has already been indicated in previous years – additive manufacturing has arrived. This solution has evolved into a massively suitable and significant manufacturing method that leads to perfectly functioning, weight-reduced, and easy-to-manufacture products. I am already looking forward to Formnext 2020.

What's the best manufacturing method for my project?

This key question concerned all Formnext visitors who want to use manufacturing opportunities in an optimal and efficient way, especially for mass production.

To answer this question, tailor-made interactive presentations of an integrated end-to-end simulation process walked booth visitors through defining the first requirements to creating a suitable concept. It also showed analysis of complex structures, up to the simulation of the manufacturing process. Not surprisingly, the Altair Inspire™ live demonstration was the highlight of the Altair booth.

Additive manufactured topology optimization parts that were shown at the Altair booth.

Within the booth area, remarkable exhibits of numerous partners were represented. Partners like amprove, M&H CNC Technik GmbH, MX3D, and Festo, demonstrated how powerful additive manufacturing can be when combined with Altair's simulation solutions.

This applies to all production methods in the field of 3D printing. Whether it's a structure and weight-optimized wheel carrier or a customized 3D printed polymer orthotic for children, combining 3D printing with optimization and simulation techniques can improve the quality of a product and decrease manufacturing time. The displayed applications not only attracted numerous visitors but demonstrated the advantages of combining innovative simulation solutions with advanced manufacturing methods.

Topology optimized robot arm developed with the help of a digital twin design process

Purmundus Challenge: Award of the best

Another highlight of this year's Formnext was the international design contest "Purmundus". Altair, who has been supporting the award for several years, had this year's honor of awarding four prizes as well as launching a category "Simulation-driven Design". 38 finalists in total were competing for their chance to win the challenge trophy. The challenge was moderated and organized by Cirp GmbH, together with the organizers of Formnext.

Additive Manufacturing is growing up

Formnext is an impressive trade fair. This year's exhibition confirmed what has already been indicated in previous years – additive manufacturing has arrived. This solution has evolved into a massively suitable and significant manufacturing method that leads to perfectly functioning, weight-reduced, and easy-to-manufacture products. I am already looking forward to Formnext 2020.