Letting Engineers Be Engineers

Not too long ago, CAE was a tool to help engineers fix the problems found in physical models. Today CAE is a cornerstone of manufacturing that solves the most serious challenges on virtual models long before the first bolt of a physical prototype is made.

As dependency on CAE has grown, so has the multitude and complexity of CAE processes. Now faced with numerous standards and requirements to reach, an engineer, who would like nothing more than to build the next breakthrough system, is taxed heavily with setting up analyses and creating reports. We have learned from our own customers that the average CAE analyst spends nearly 70% of his time in analysis setup and reporting that includes largely “repetitive, mundane and error-prone activities.”

That leaves a mere 30% of time in which an expert resource can make expert decisions. Simply put, an engineer has little time to be an engineer. Though the help of macros and scripts can automate some CAE challenges, these options also include requirements of their own including scripting or programming in addition to regular maintenance and upgrading.

So the big challenge today is how to provide a reliable, robust and scalable capability that can meet a particular automation requirement and be available on the fly to engineers and methods teams?

We looked around for solutions and our minds wandered. We thought about what made us want to be engineers? As kids, we played with LEGO, and were inspired by the limitless creations—simple to sublime—that we could construct from one pile of common interlocking blocks.

This got us thinking. Could CAE start that simply? Could we combine common CAE objects and use them to construct complex processes? Could we break down CAE into blocks basic enough so that non-experts could feel comfortable building processes with them?

Inspired… we took a lean team—inversely proportionate with creativity—and developed HyperWorks Automate. In a year and a half, we created a system of simple CAE building blocks that customers could drag, drop and connect to construct tailored, repeatable processes—process automation on the fly.

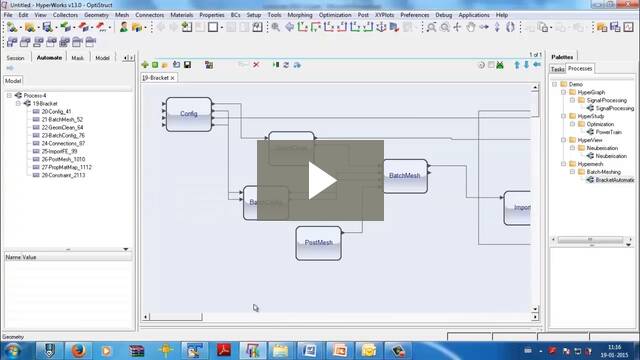

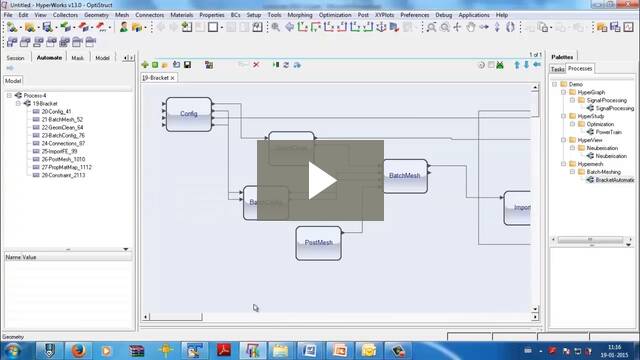

The following videos show Automate in use through HyperMesh, HyperView and HyperGraph.

The video provide a glimpse of how Automate helps companies capture the know-how of repetitive, time-consuming tasks, thus freeing engineers to spend time on making good engineering decisions.

Manufacturing industries have shown us the need for CAE process automation and standardization. Automate is a tool that delivers a solution to these issues and elevates engineers from repeating tasks to engineering breakthrough results!

As dependency on CAE has grown, so has the multitude and complexity of CAE processes. Now faced with numerous standards and requirements to reach, an engineer, who would like nothing more than to build the next breakthrough system, is taxed heavily with setting up analyses and creating reports. We have learned from our own customers that the average CAE analyst spends nearly 70% of his time in analysis setup and reporting that includes largely “repetitive, mundane and error-prone activities.”

That leaves a mere 30% of time in which an expert resource can make expert decisions. Simply put, an engineer has little time to be an engineer. Though the help of macros and scripts can automate some CAE challenges, these options also include requirements of their own including scripting or programming in addition to regular maintenance and upgrading.

So the big challenge today is how to provide a reliable, robust and scalable capability that can meet a particular automation requirement and be available on the fly to engineers and methods teams?

We looked around for solutions and our minds wandered. We thought about what made us want to be engineers? As kids, we played with LEGO, and were inspired by the limitless creations—simple to sublime—that we could construct from one pile of common interlocking blocks.

This got us thinking. Could CAE start that simply? Could we combine common CAE objects and use them to construct complex processes? Could we break down CAE into blocks basic enough so that non-experts could feel comfortable building processes with them?

Inspired… we took a lean team—inversely proportionate with creativity—and developed HyperWorks Automate. In a year and a half, we created a system of simple CAE building blocks that customers could drag, drop and connect to construct tailored, repeatable processes—process automation on the fly.

The following videos show Automate in use through HyperMesh, HyperView and HyperGraph.

The video provide a glimpse of how Automate helps companies capture the know-how of repetitive, time-consuming tasks, thus freeing engineers to spend time on making good engineering decisions.

Manufacturing industries have shown us the need for CAE process automation and standardization. Automate is a tool that delivers a solution to these issues and elevates engineers from repeating tasks to engineering breakthrough results!