Modern organic architecture with ESAComp

What is organic architecture?

First coined by Frank Lloyd Wright, it describes his environmentally-integrated approach to architectural design. Embraced by architects worldwide and across the ages, modern organic buildings tend to avoid linear or rigidly geometric shapes by using curves to suggest organic forms, often coupled with natural materials.

Varna Regional Library: An approach for an interactive space for 21st century

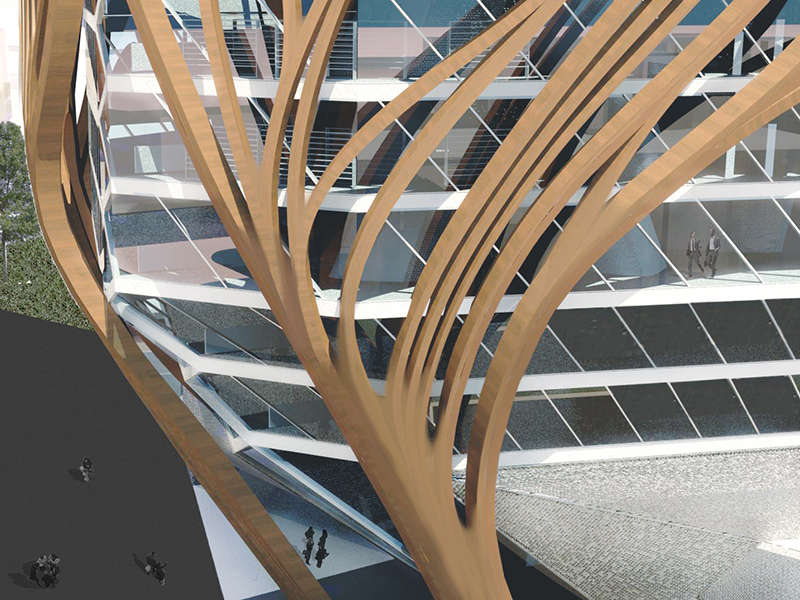

When Varna in Bulgaria wanted to consolidate their libraries to create the "Varna Regional Library", a new and active public space in the centre of the city, they launched an open international architectural competition and invited architects across the world to participate. One of the entries, from Digital Architects (Vienna, Austria) and Archicomplex Ltd (Tokyo, Japan), proposed an innovative wooden composite façade that acts as both an external support structure for the building and louver system allowing a comfortable natural light into the library.

“We applied new and innovative simulation technology to engineer strong, lightweight wooden composite sections capable of withstanding all the necessary load cases”, says architect Atanas Zhelev, from Digital Architects, “Altair’s ESAComp software was ideal for the preliminary laminate analysis, to evaluate the structural component behaviour along with the development of the joint system”.

Learn more about “Use of Composite Materials in Organic Architecture”

Join our webinar on November 14, hosted by Composites World, to see some recent applications where —with the help of advanced simulation tools offered by Altair HyperWorks suite — architects have found original solutions to balance design, structural strength and cost. Learn more about Digital Architects wood-composite materials with their application to the proposed innovative façade for the Varna Regional Library in Bulgaria.

Altair - ESAComp

“We usually see ESAComp used for fibre-reinforced, polymer matrix composites. Nowadays these sectors are increasingly wide, from our roots in the high-performance aerospace sector to effectively wherever laminated composite materials are being used – an example is for civic structural art installations: “Leonardo” in Finland; “Mae West” in Germany. Although conventional plywood and balsa wood, a core material for sandwich panels, are already in our database, this is a successful application of ESAComp that clearly shows the software’s capability to assist learning and understanding of complex wood-composite materials along with trade-off studies, structural analysis of parts and joint details for innovative architects”. Markku Palanterä, Altair Finland

Wood composite material development

Composites offer the designer ability to create a material and so engineer its properties to meet individual load cases and environments. Such infinite possibilities can be daunting and a big step away from the more conventional way of working with a material with known set of characteristics. It is here that designers can be aided by software such as Altair’s ESAComp either working alone or along with HyperWorks advanced simulation and optimization software suites.

The wood-carbon composite comprises thin sheets of birch wood, with layers of carbon fibre interspersed between them, all adhesively-bonded together: a classic plywood type construction, but with a modern twist provided by an advanced composite reinforcement to enhance structural performance.

ESAComp was used to first understand wood laminate constructions before adding in the carbon plies. Combinations of birch ply thickness and position were examined to determine how much structural strength changes compared with a laminate having equal thickness plies. Then the orientation of carbon plies on the mechanical performance was examined, followed by an analysis for the different load cases in the façade components.

Structural component behaviour

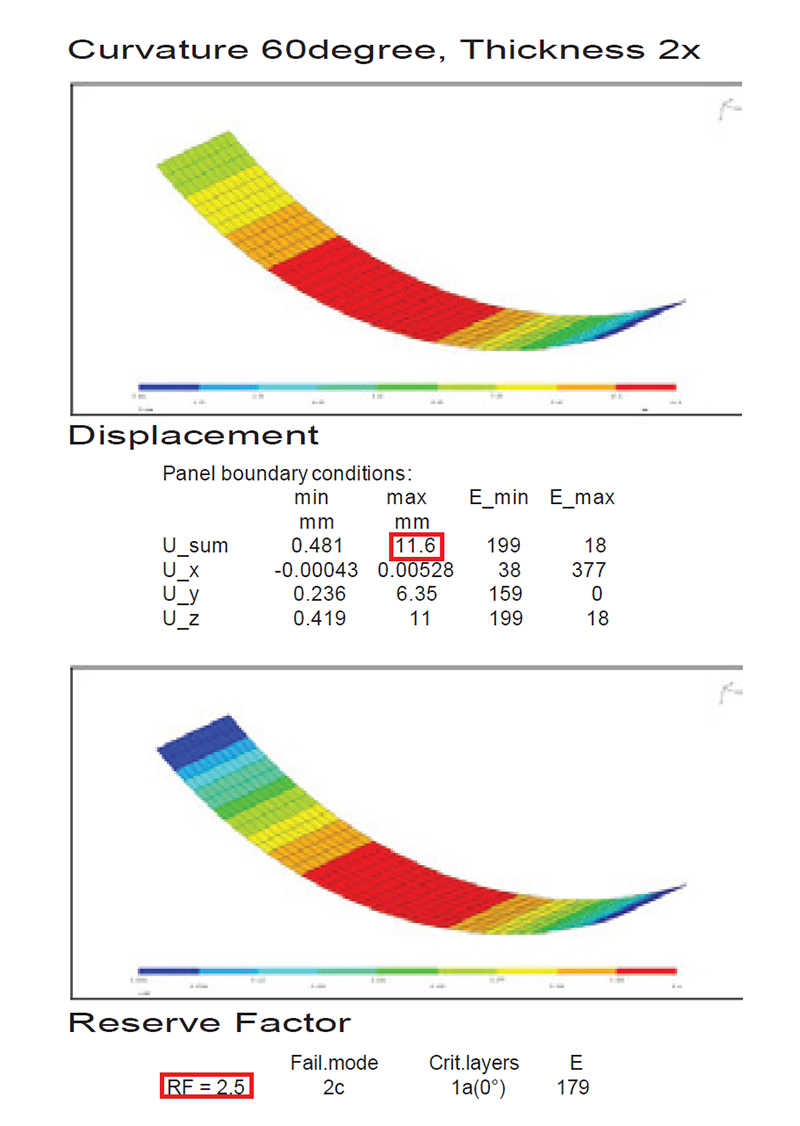

Early in the design process, “Trade-off studies” working with simplified geometries helps narrow down possible concepts and provides valuable input for later, more detailed design stages.

Using the optimized wood-composite laminate, when the structure was divided into three simplified main façade elements (vertically-oriented; horizontally-oriented; transition elements having different radius of curvature), each of the correct dimensions, their precise structural and wind load cases were examined.

As the wooden lamellas split and join at different points of the overall structure, the analysis showed that the more horizontally-oriented elements needed to be thicker compared with the more vertically-oriented elements owing to the structural load being larger than the wind load and to the decrease in performance of the composite to out-of-plane shear.

Joint system development

For a successful design, the joining of composites needs careful consideration early in the design. Joint geometry, incorporating extra material in adhesive bond zones, is common. Drilling holes in composites disrupts load paths within materials and, if not done properly can cause damage that may cause long-term degradation: both structurally and aesthetically.

To join the façade to the concrete slabs of the building, bolted and bonded joints were evaluated. Holes drilled for bolts effectively damage the wooden façade and require the structure to be supported by big, heavy steel members that spoil the elegant, fluid design of the façade. The solution was a newly-developed epoxy concrete. This material is both a structural adhesive, which makes it easier to bond with the wood, and being a concrete makes it easy to bond with the concrete slab. Joint analysis performed in ESAComp determined the thickness of the joining member required to make this process possible. The responses of two different lay-ups for the carbon beam enabled the thickness of the beam to be minimized in order for the façade retain its elegance.

Active Grid Monocoque: Next step for wood-carbon composites

Continuing their experiments with wood–carbon composites, in January 2017 Digital Architects structurally-certified a wood-carbon composite material for architectural use, along with the “Active Grid Monocoque” construction method required to manufacture ultra-thin lightweight, long-span roof structures using a wood-carbon hybrid.